500kv transmission line insulator live water washing method

A technology for transmission lines and insulators is applied in the field of anti-pollution flashover for high-voltage transmission lines, which can solve the problems of anti-pollution technology and low efficiency, achieve good economic and social benefits, reduce line power outages, and prevent pollution flashover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the method for flushing charged water for 500kV transmission line insulators of the present invention will be described in detail below in conjunction with the accompanying drawings.

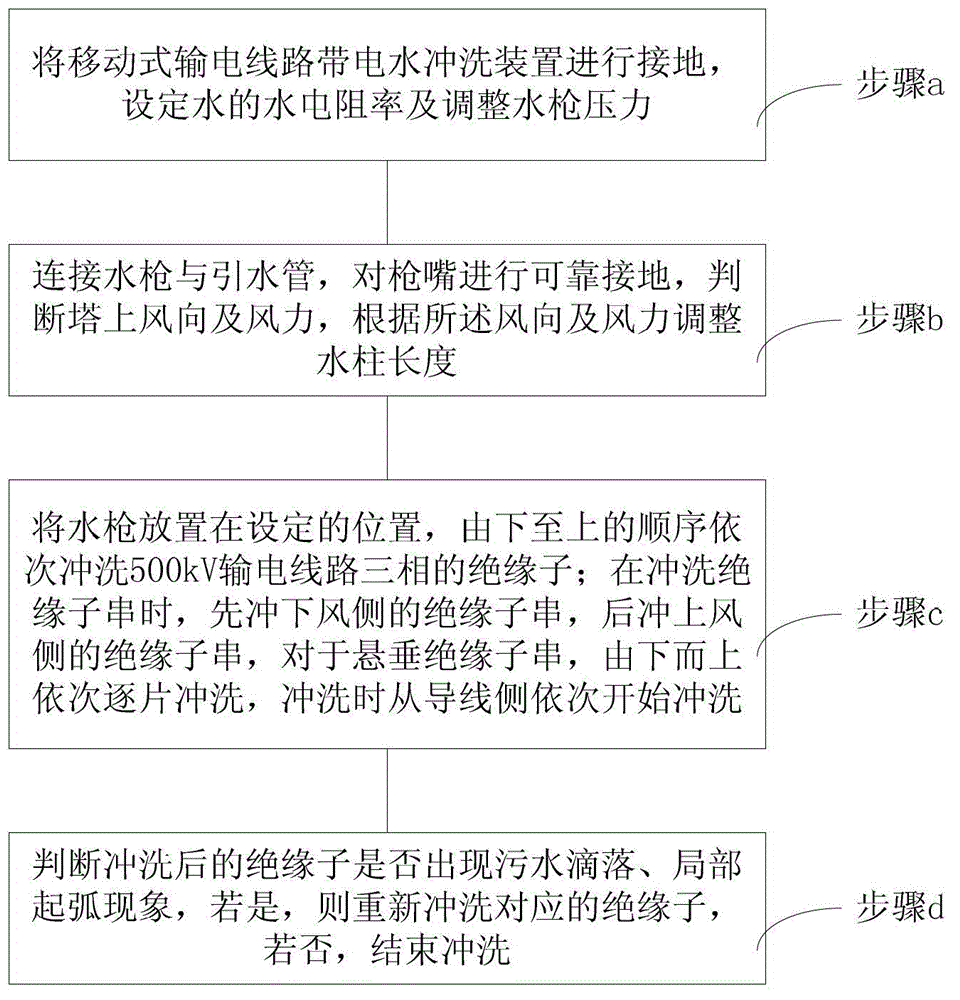

[0016] figure 1 It is a flow chart of the 500kV transmission line insulator charged water flushing method of an embodiment, comprising the steps:

[0017] Step a. Ground the live water flushing device of the mobile transmission line, set the water resistivity of the water and adjust the pressure of the water gun.

[0018] Specifically, after the delivery vehicle arrives at the job site, the ground staff checks the situation of the live water flushing device of the mobile transmission line, first grounds the delivery vehicle, and then lays the water pipe under the iron tower under the control of the hydraulic device to test the water quality of the water. Resistivity and adjust water gun pressure. Preferably, the water resistivity of the water is set to be grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com