Connecting clamp of distribution transformer bushing lead screw rod and line wire

A line and screw technology, applied in the direction of transformer/inductor coil/winding/connection, conductive connection, electrical component connection, etc., can solve the problem of small contact area between wiring board and lead screw, loose contact of lead screw and low power supply reliability and other issues, to achieve the effect of increasing enterprise and social benefits, improving contact reliability, and improving power supply reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

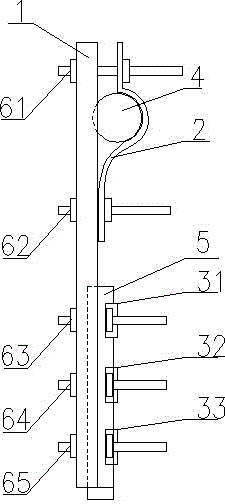

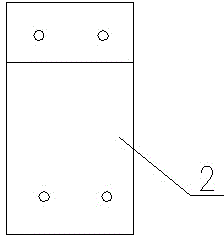

[0017] Such as figure 1 As shown, a wire clamp for connecting the lead screw of a distribution transformer bushing to a line conductor of the present invention includes a screw clamp plate 2, a long clamp plate 1, a line conductor pressing plate 31, 32, 33, the screw clamp plate 2 and the upper end of the long clamp plate 1 The lead screw 4 is placed between the two ends of the screw splint 2 and the upper end of the long splint 1 are fixedly connected by bolts 61, 62, and the line conductor 5 is placed between the lower end of the long splint 1 and the line conductor pressing plates 31, 32, 33. The lower end of the clamping plate 1 is fixedly connected with the line conductor pressing plates 31, 32, 33 by bolts 63, 64, 65.

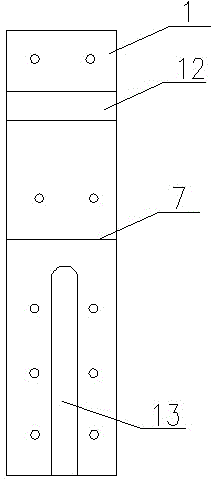

[0018] Such as figure 2 As shown, the long splint 1 is a rectangular copper-aluminum transition plate, the upper end is a copper plate, the lower end is an aluminum plate, the copper plate and the aluminum plate are welded together, and 7 is a welding line; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com