Method for rapidly detecting stability of steel slag fine aggregate

A fine aggregate and stable technology, applied in the field of steel slag mortar and environmentally friendly steel slag mortar, can solve problems such as engineering hazards, achieve the effects of maintaining environmental coordination, saving resources, and reducing the risk of resource depletion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

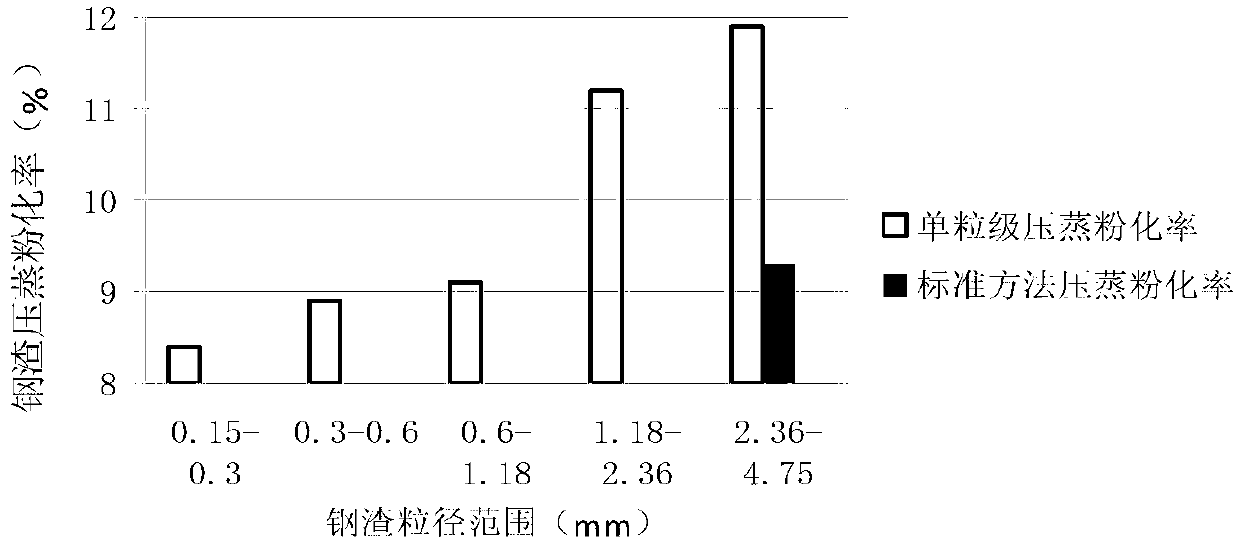

[0014] The biggest difficulty in preparing construction mortar from steel slag solid waste is that the steel slag with a short stacking period will cause the instability of the mortar volume. This example provides a method for quickly detecting the stability of steel slag fine aggregates. The steel slag particles within half a year are divided into five particle sizes ranging from 0.15mm to 0.3mm, 0.3mm to 0.6mm, 0.6mm to 1.18mm, 1.18mm to 2.36mm and 2.36mm to 4.75mm, and measure each particle size immediately The autoclaved pulverization rate of the aggregate itself is based on the mutation point of the autoclaved pulverization rate of each particle size, and the maximum particle size of the selected steel slag fine aggregate is determined, and then the particle size is used as the upper limit to prepare different steel slag content. The construction mortar test block is maintained for 3 days as standard, and the pressure steaming test is carried out. According to the volume c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com