A Controlled Deformation Machining Technology of Thin-walled Disk Parts

A technology for deformation processing and thin-walled disks, which is applied in the field of thin-walled disk parts control deformation processing technology, can solve the problems of aggravating the stress and deformation of parts, and long time for empty cutting, so as to improve machining accuracy, control deformation problems, and improve The effect of processing efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

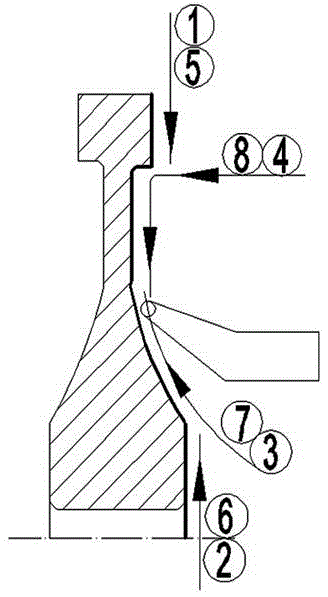

[0011] This embodiment provides a controlled deformation processing technology for thin-walled disk parts, which is characterized in that: the thin-walled disk parts controlled deformation processing technology is used to process disk parts, and the cutting direction is as shown by the arrow in the figure. First turn the end face, and then adopt the scattered cutting method, so that the same surface can be processed in multiple scattered cutting processes;

[0012] Cutting 1 is, the direction of cutting is from outside to inside, serial number 1, this way of cutting makes the cutting force of the part point to the center of the wheel, and improves the rigidity of the part; cutting 2, number 2, is to process from the center of the The force is directed to the inside of the disc body, which enhances the compressive stress of the disc body, which is beneficial to the deformation and service life of the parts; tool pass 3, serial number 3, is machining from the high point to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com