Energy-saving middle-frequency-inverting automatic gang bonder with multiple transformers

A technology for transformers and group welding machines, which is applied in the field of energy-saving intermediate frequency inverter multi-transformer automatic group welding machines, can solve the problems of uneven current distribution of solder joints, large volume, low production efficiency, etc., and achieves high automatic control precision of solder joints. High power efficiency and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

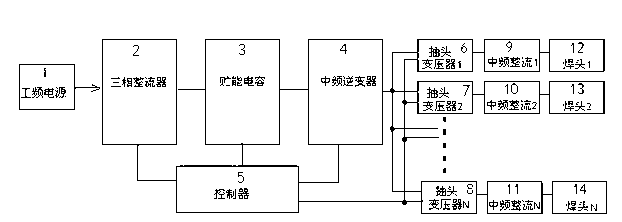

[0010] Such as figure 1 The intermediate frequency inverter power supply technology is applied as shown in the figure, and the power frequency alternating current is converted into high voltage direct current through a three-phase rectifier. The energy is stored and smoothed by the energy storage capacitor to become a stable direct current, and then the high-power IGBT (insulated gate bipolar transistor) The intermediate frequency inverter composed of power is converted into intermediate frequency PWM pulse wave, and then the intermediate frequency pulse width is adjusted by the controller to form a constant voltage or constant current output. It is converted into medium-frequency pulsating low-voltage direct current and loaded onto the welding head to weld multiple workpieces. In this scheme, since a high-voltage DC circuit is equipped with a large-capacity energy storage filter capacitor, the stored electric energy is released when the spot welding machine works instanta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com