Drawer bin purely mechanical type capturing location device

A grasping and positioning, purely mechanical technology, applied in metal processing and other directions, can solve the problems of changing production, inconvenient moving operation, etc., to achieve the effect of wide range of use, improved stability, and improved grasping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

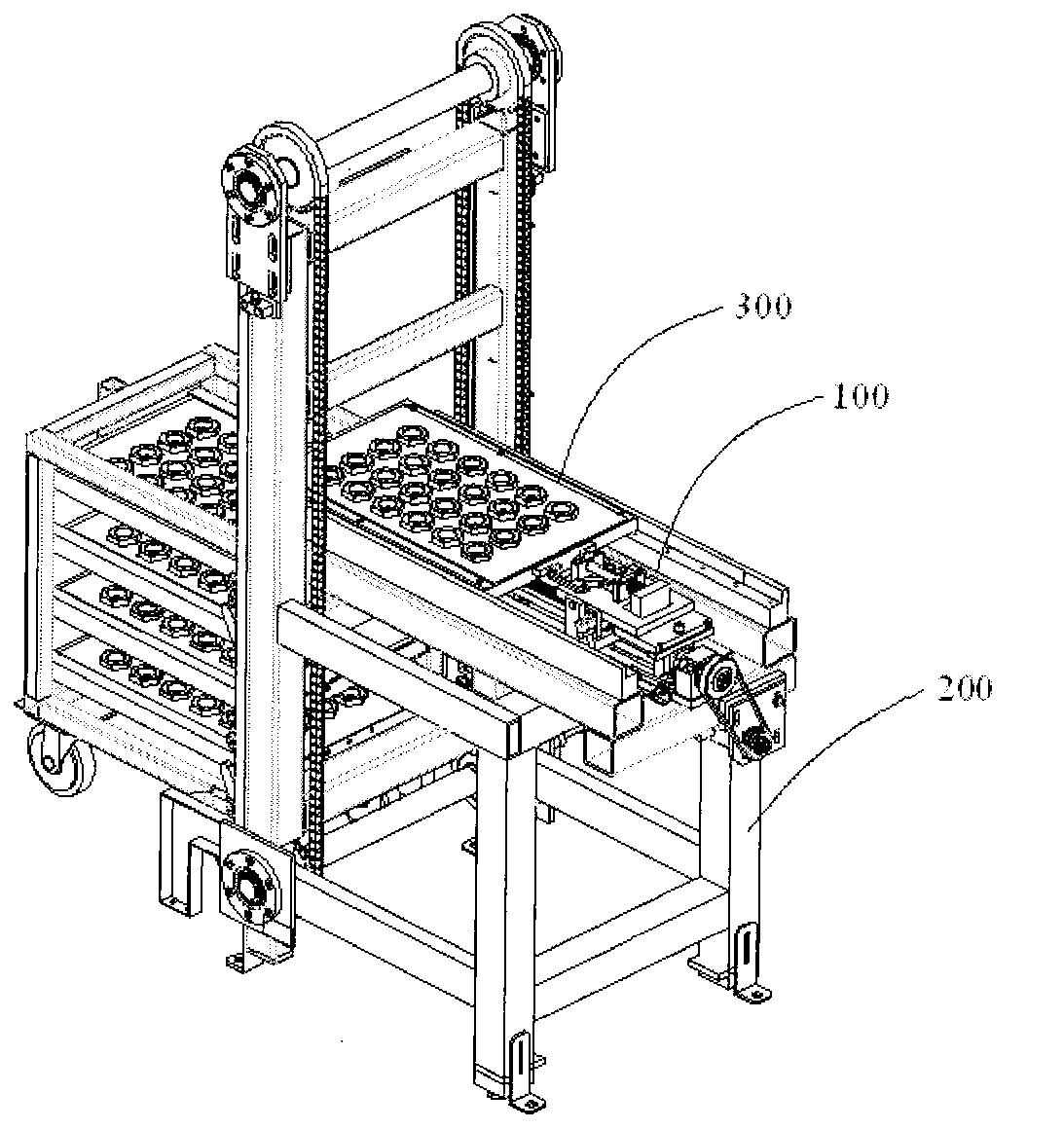

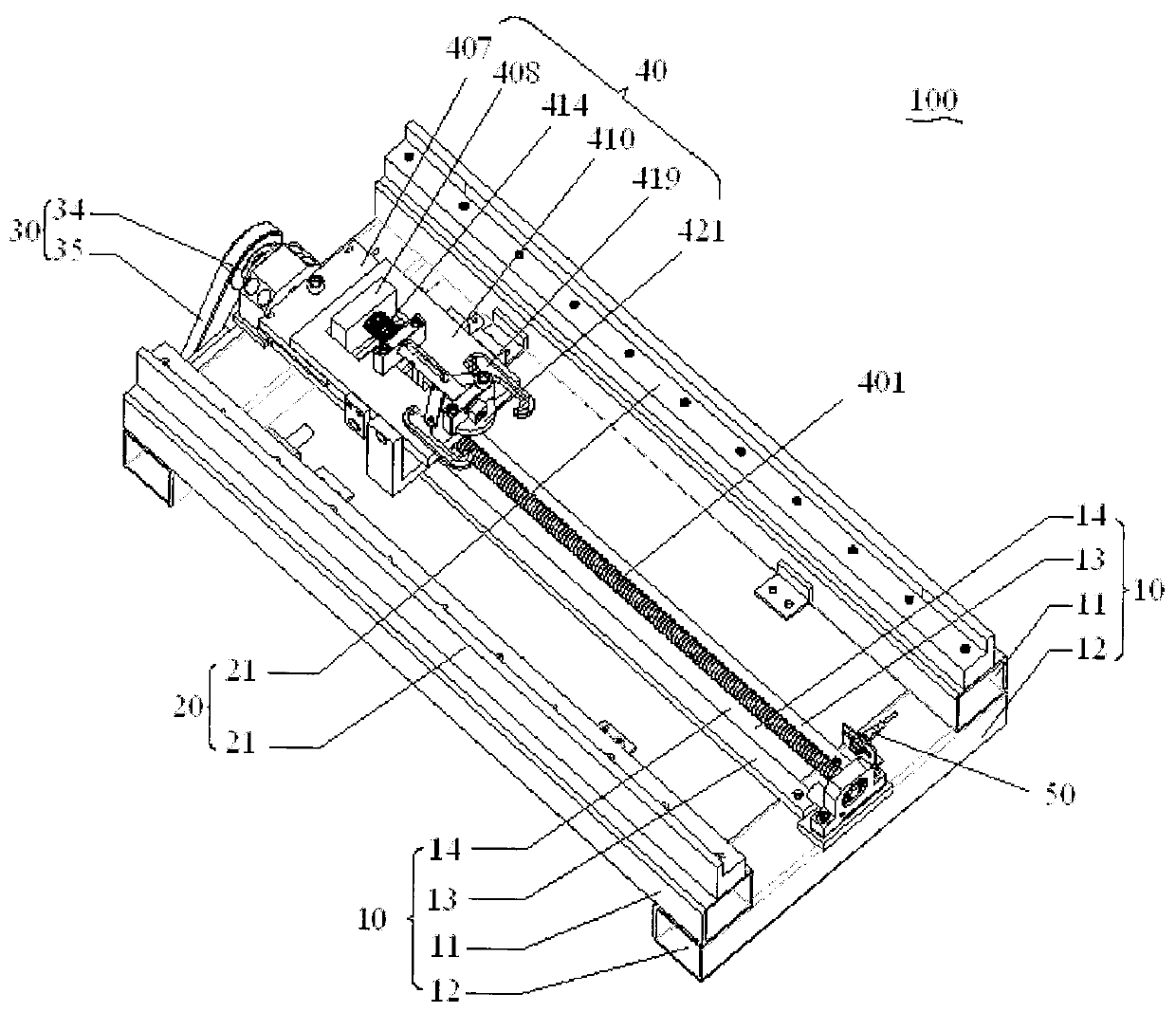

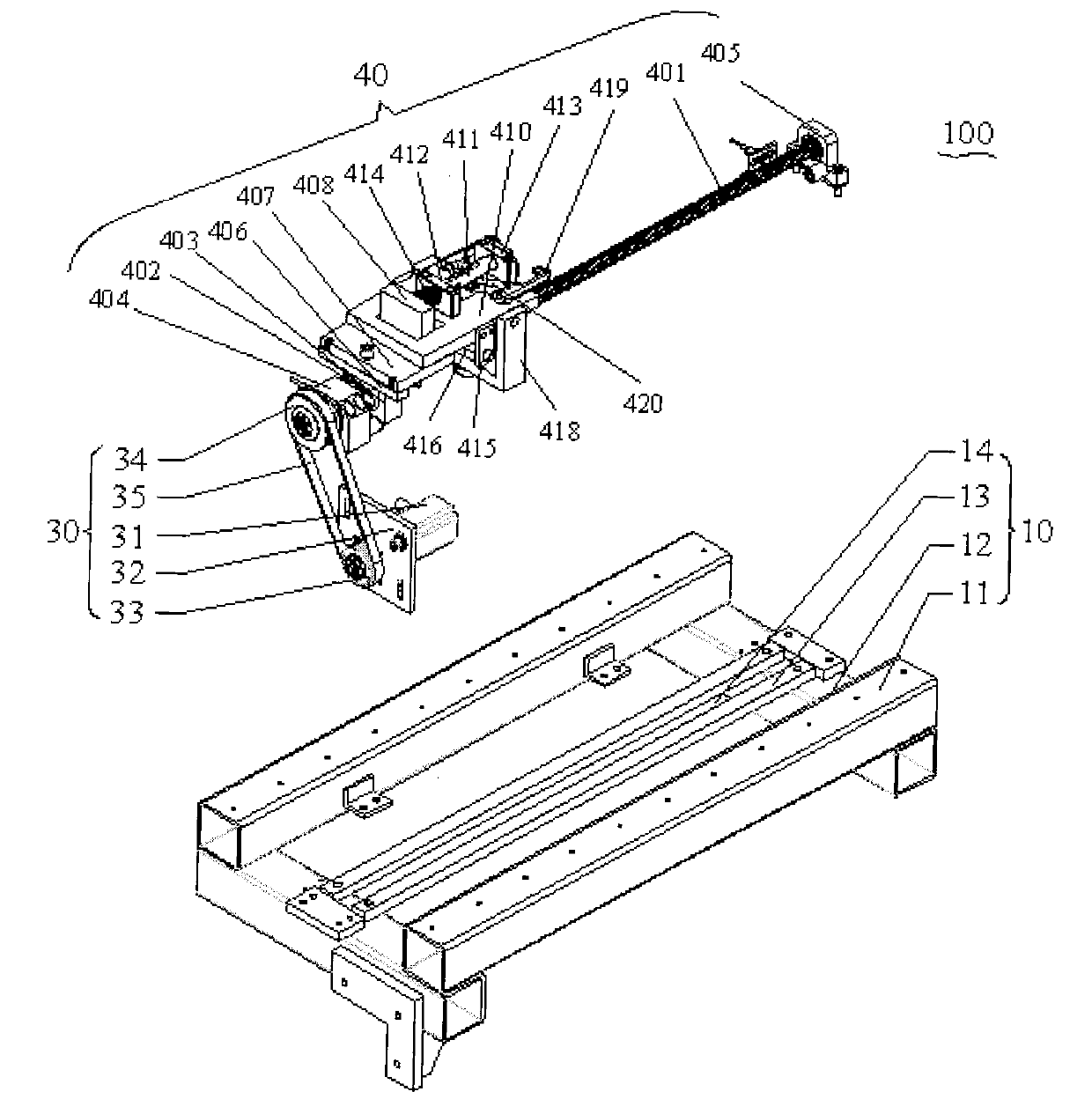

[0028] In conjunction with the accompanying drawings, the present invention is further described, please refer to figure 1 , the purely mechanical grasping and positioning device 100 for the drawer silo is installed on the machine tool 200 to grasp the state of the pallet 300, combined with Figure 2 to Figure 7 The drawer silo purely mechanical grasping and positioning device 100 includes a mounting frame 10, a tray guide mechanism 20, a ball screw driving mechanism 30, a drawer tray grasping mechanism 40 and a control mechanism 50; the mounting frame 10 includes two beams 11, two A longitudinal beam 12 and two guide strips 13, threaded holes are set above the two cross beams 11, one end of the guide strip 13 is installed on the longitudinal beam 12, and the other end of the guide strip 13 is installed on the other longitudinal beam 12, the two guide strips 13 is installed to form a guide space 14; the tray guide mechanism 20 includes two limit blocks 21, the end faces of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com