Waste extraction device

A technology for extracting equipment and waste, applied in metal processing and other directions, can solve the problems of complicated removal process and expensive equipment, and achieve the effects of improving process flow, simplifying structure and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the implementations shown in the accompanying drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structures made by these implementations Equivalent transformation or substitution all belong to the protection scope of the present invention.

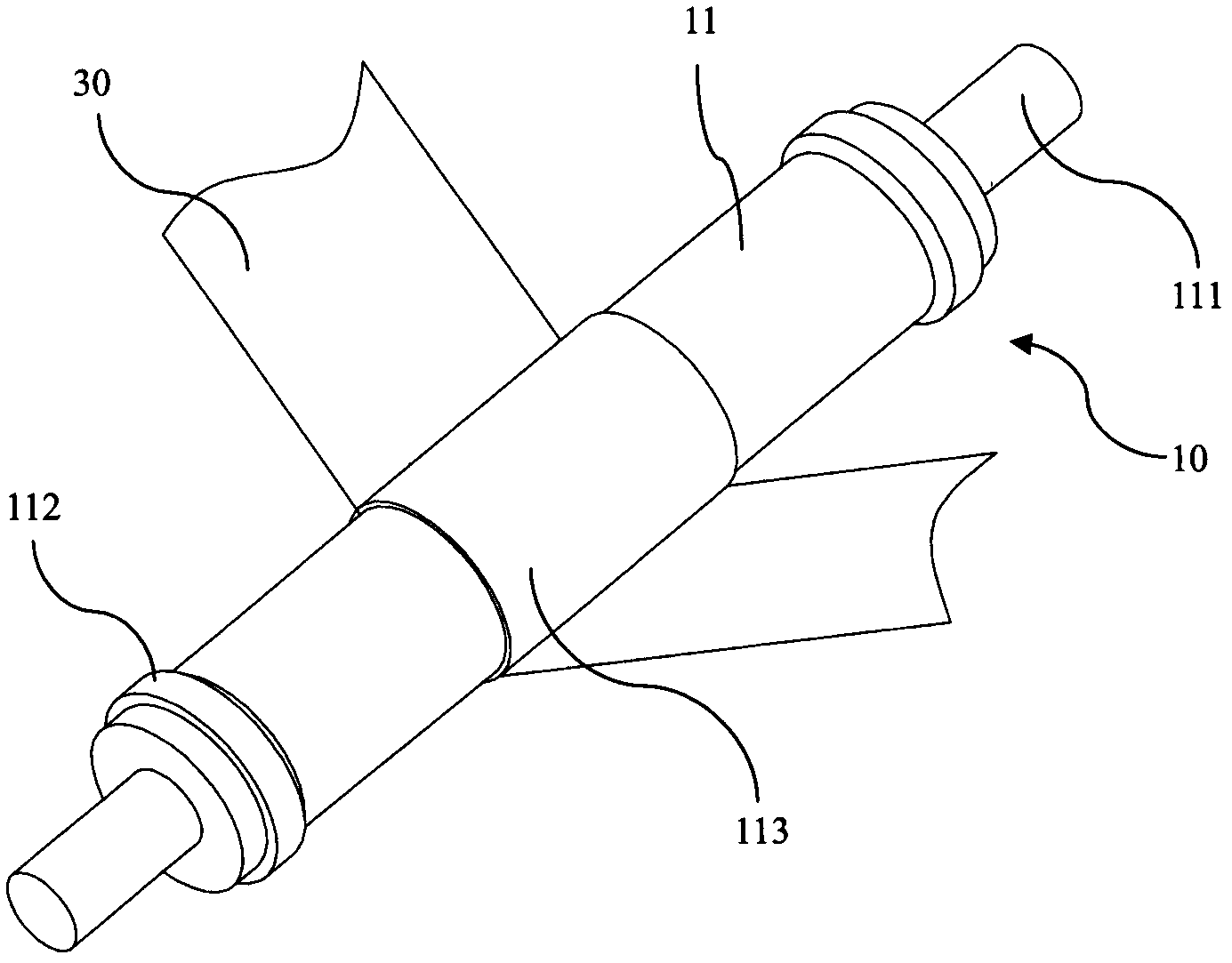

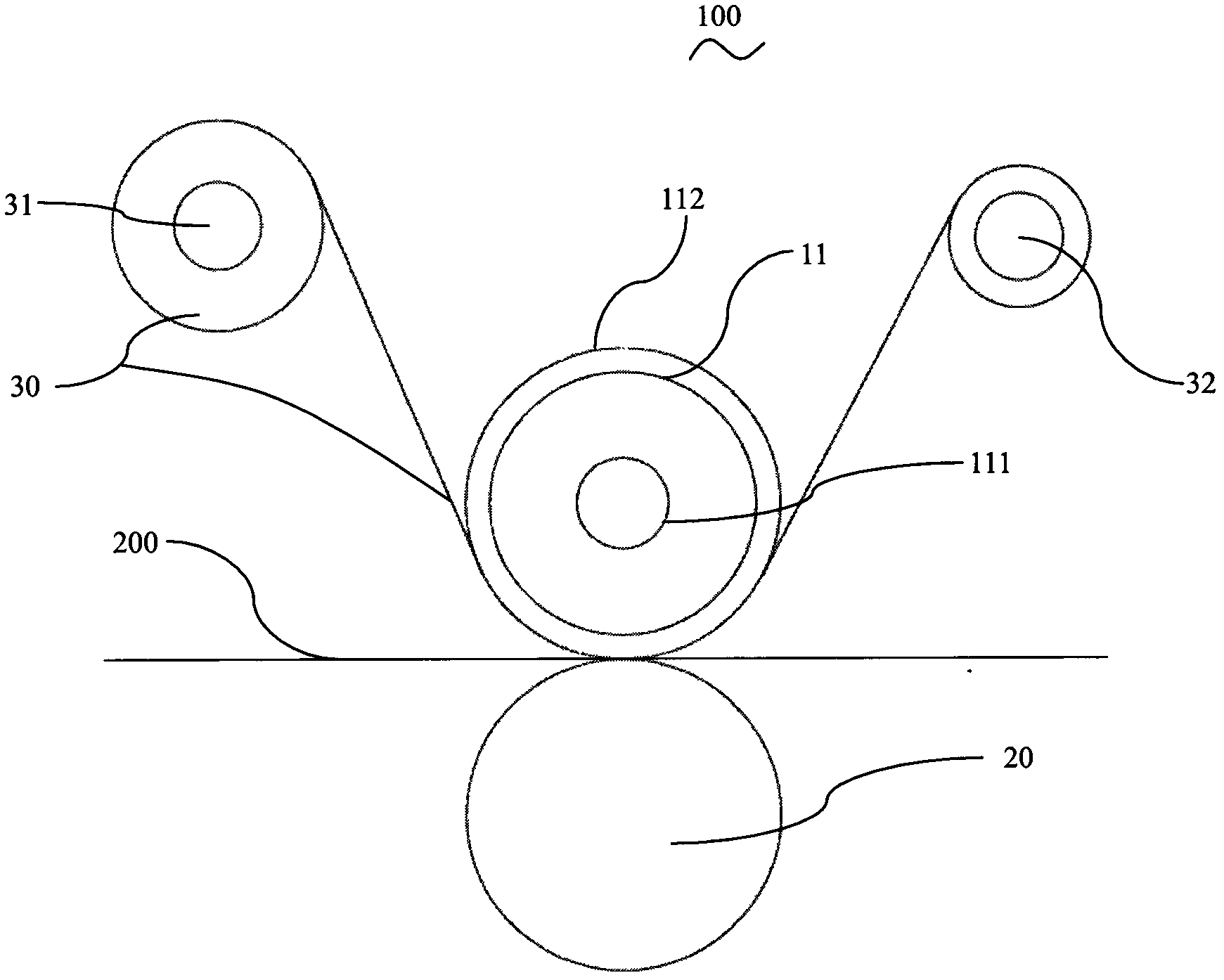

[0022] Such as figure 1 As shown, it is a three-dimensional schematic diagram of the cooperation of the extraction knife 10 and the extraction tape 30 of the waste extraction device 100 of the present invention. The waste extraction device 100 includes: the extraction knife 10, which includes: a body 11, which protrudes laterally to form a ring The positioning device 112 protrudes from the two ends of the main body 11 along the longitudinal direction of the main body 11 to have roller shafts 111. In this embodiment, the main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com