Self-tipping semi-trailer

A technology of semi-trailer and axle, which is applied in the direction of inclined load-carrying vehicles, etc. It can solve the problems of unfavorable loading and unloading of rescued vehicles, unfavorable vehicle up and down, unfavorable vehicle loading and unloading, etc., so as to improve loading, unloading and transportation efficiency, reduce economic costs, and facilitate loading and unloading. Goods are convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

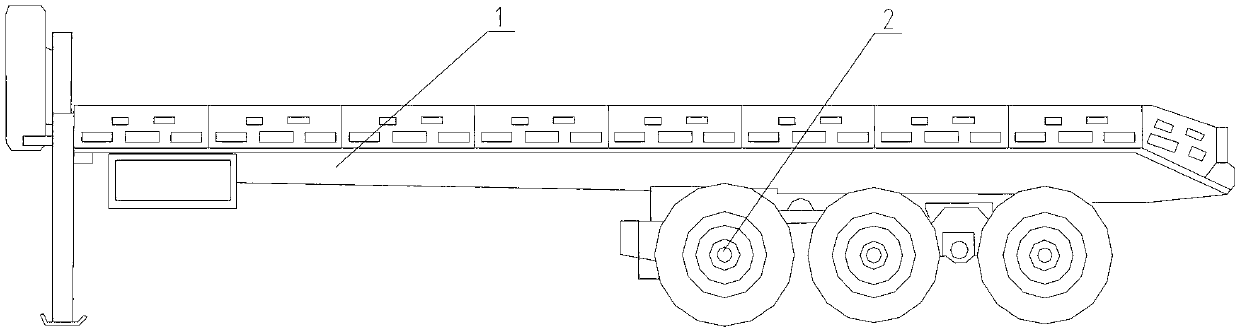

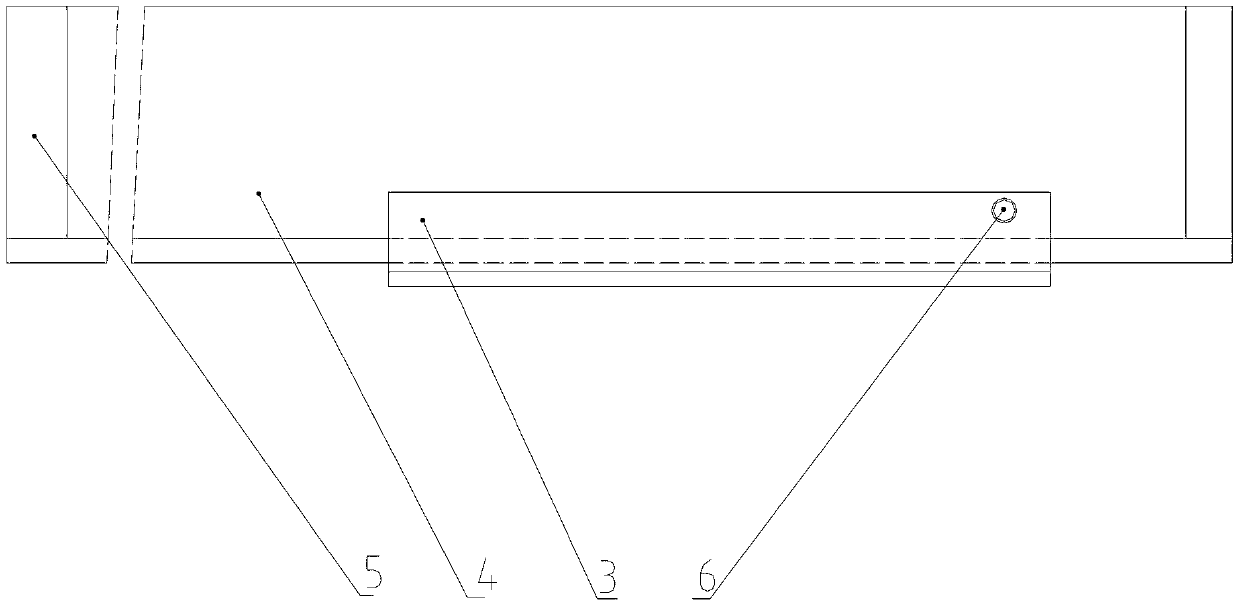

[0025] Such as figure 1 and figure 2 As shown, a self-tilting semi-trailer of the present invention includes a connected vehicle frame 1, an axle 2, an electrical system (not shown in the figure) and an air circuit system (not shown in the figure) for controlling power, and the axle 2 A sliding device is also provided between the vehicle frame 1, and the sliding device includes a connected guide rail 3 and a slide rail 4, positioning blocks 5 provided at both ends of the slide rail 4, for fixing the guide rail 3 and the sliding rail. The fixed pin shaft 6 of the rail 4, the slide rail 4 is welded on the bottom of the vehicle frame 1, and the axle 2 is fixed on the bottom of the guide rail 3.

[0026] In the above embodiment, the slide rail 4 can slide along the guide rail 3 , so that the vehicle frame 1 fixed on the top of the slide rail 4 can move along the guide rail 3 together with the slide rail 4 .

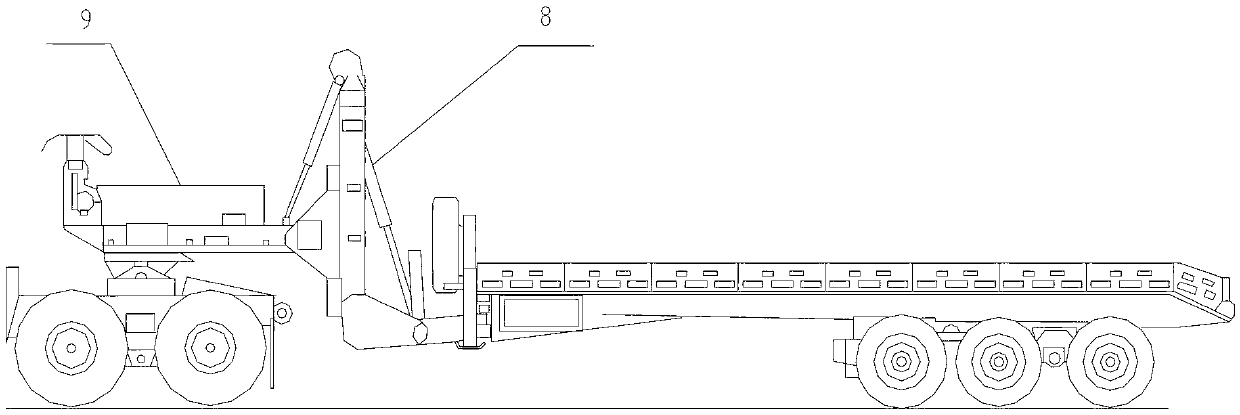

[0027] Such as image 3 and Figure 4 As shown, when using the self...

Embodiment 2

[0030] Such as figure 2 , Figure 5 and Figure 6 As shown, a self-tilting semi-trailer, its basic structure is set with embodiment 1, specifically, also includes the following settings:

[0031] The slide rails include a first slide rail 401 and a second slide rail 402, the first slide rail 401 and the second slide rail 402 are arranged in parallel, and the guide rail 3 is located between the first slide rail 401 and the second slide rail 402 Between the rails 402, the guide rails 3 are vertically connected with the first slide rail 401 and the second slide rail 402 respectively;

[0032] The bottom of the front end of the frame 1 is provided with a scalable leg 7; the front end of the frame 1 is provided with a socket (not shown in the figure); the air circuit system includes a brake chamber, and the brake The air chamber houses the spring for the parking brake (not shown).

[0033] In the above-mentioned embodiment:

[0034] Both the first slide rail 401 and the second ...

Embodiment 3

[0038] Such as figure 2 and Figure 7 As shown, a self-tilting semi-trailer, its basic structure is set with embodiment 1, specifically, also includes the following settings:

[0039] There are three groups of axles, from front to back are the air suspension axle 201, the first balance beam suspension axle 202 and the second balance beam suspension axle 203, the first balance beam suspension axle 202 is connected to the guide rail 3 through the first balance beam (not shown in the figure), and the second balance beam suspension type axle 203 is connected to the guide rail 3 through the second balance beam (not shown in the figure); the air path The system includes a double-pipe air brake device, which are service brake control parts and parking brake control parts.

[0040] In the above embodiment, the air suspension type axle 201 is a constant load type, and the loads of the first balance beam suspension type axle 202 and the second balance beam suspension type axle 203 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com