Sliding plate conveying system

A conveying system, slide technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

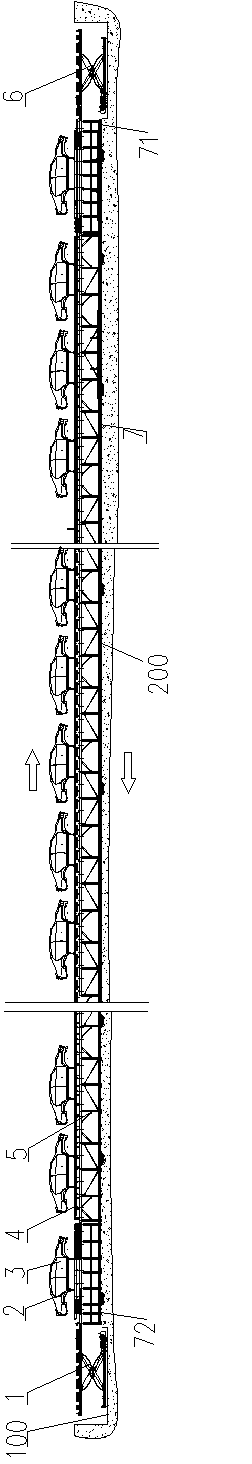

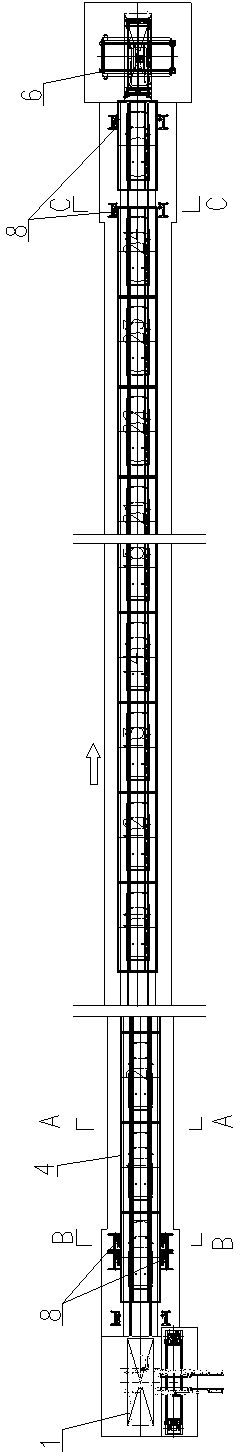

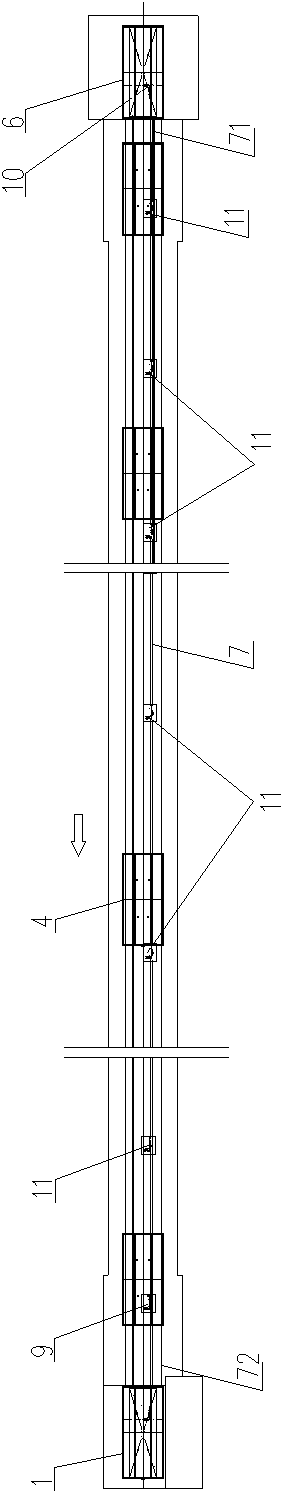

[0025] like Figure 1 to Figure 7 As shown, an embodiment of a skateboard conveying system, the skateboard conveying system in this embodiment includes a working conveying track 4 arranged in a pit 100 for moving and conveying a skateboard carrying an object during use, where the working conveying The track 4 is fixed on the support 5 preset in the pit 100 along the extension direction of the working conveying track. The support 5 supports the working conveying track at a high place at the bottom of the pit. The support 5 is a steel structure support frame. On both sides of the working conveying track 4, a friction drive mechanism 8 for frictionally cooperating with the slide plate to drive the friction to move quickly on the working conveying track 4 is arranged. The working conveying track 4 extends along a straight line, and the two ends of the working conveying track 4 are The input end and the output end, in the pit 100, the return conveying device 200 for transporting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com