Remote control feeding machine

A technology of feeding machine and remote control device, which is applied in the field of remote feeding machine, can solve problems such as incompetence, high cost, and time-consuming, and achieve the effects of improving production efficiency, low production cost, and convenient batching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

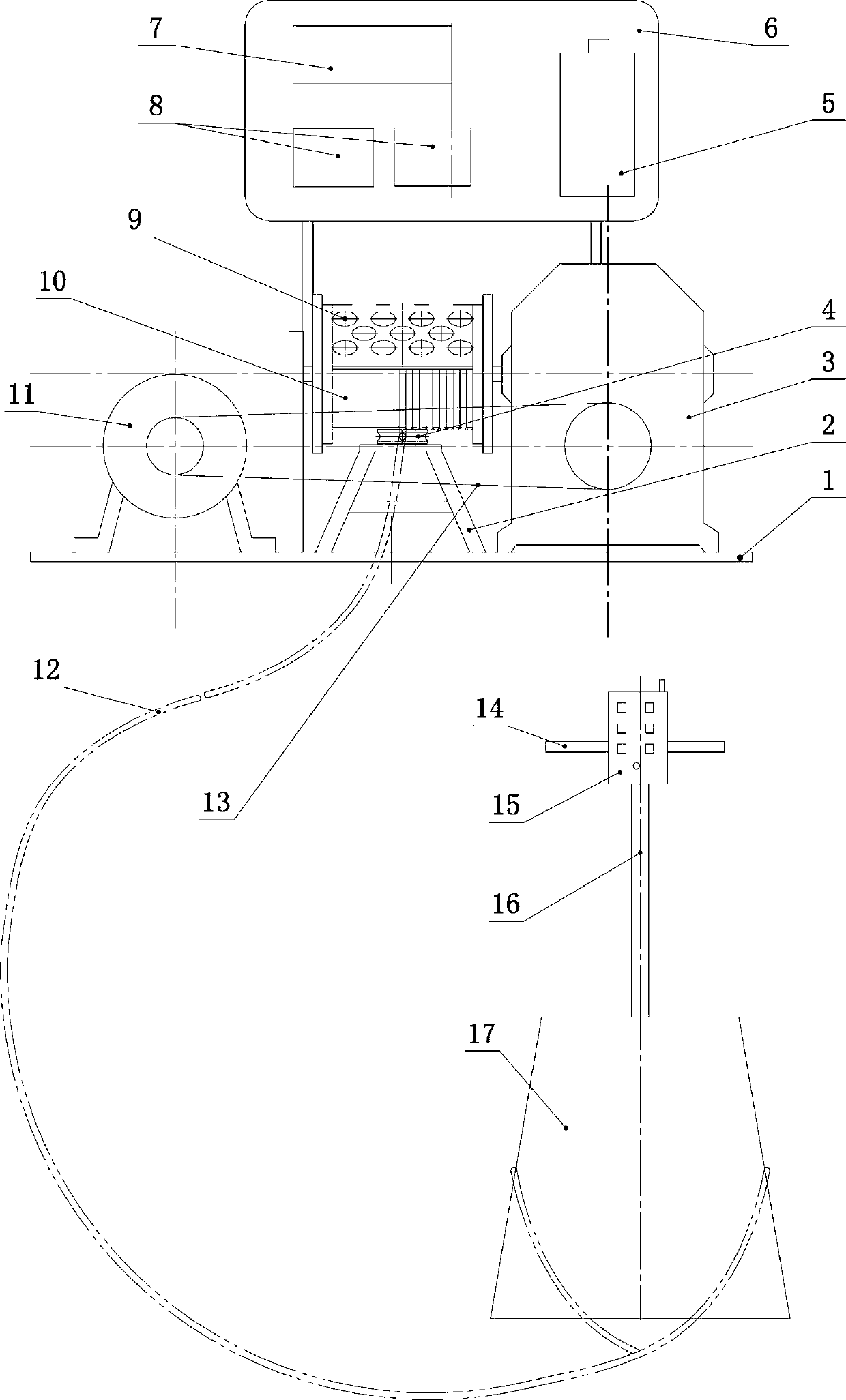

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0019] A remote control feeding machine, such as figure 1 As shown, it includes a base 1, a motor 11 is fixedly installed on the base 1, a winding roller 10 is installed in relative rotation on the base 1, the winding roller 10 is connected with the motor 11 in transmission, and a steel rope 12 is wound outside the winding roller 10, and the steel rope 12 is additionally One end is fixedly connected with a feeding shovel, the feeding shovel includes a shovel head 17, the upper end of the shovel head 17 is fixedly connected with a shovel bar 16, and a remote control device 15 is fixedly installed on the shovel bar 16; the remote control feeder also includes an instrument box 6, an instrument The box 6 is provided with an AC contactor 8 and a remote control receiver 5 connected to each other. The remote control receiver 5 corresponds to the remote cont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap