Wind sweeping material distributing box

A cloth box and air sweeping technology, applied in the field of cloth box, can solve the problems of non-adjustable cloth effect, inability to cope with material collapse, material blocking, etc., and achieve the effect of improving work efficiency, improving material collapse, and alleviating material collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further explained below according to the drawings and specific embodiments of the specification.

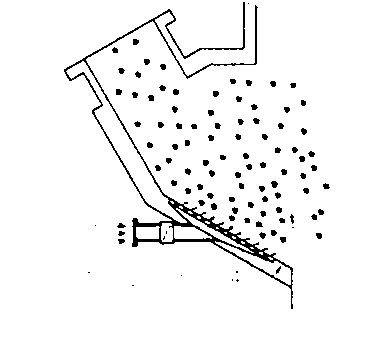

[0011] Such as figure 1 As shown, the air-swept distribution box includes an airflow connecting pipe 1, a distribution box 3, and an airflow distribution plate 4. The distribution platform of the distribution box 3 is provided with an airflow distribution plate 4, and the airflow distribution plate 4 is sealed and connected to the airflow Take over one end of 1.

[0012] According to specific production conditions, the included angle between the axis of the airflow connecting pipe 1 and the airflow distribution plate 4 is between 0° and 180°.

[0013] The airflow connecting pipe 1 is provided with a regulating valve 2, which is used to control the air volume of the compressed air, and the regulating valve 2 can dynamically control the amount of the compressed air blown in according to the change of the feeding amount so as to realize the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com