Plastic bottle cap capping machine

A technology of capping machine and bottle caps, which is applied in the direction of flanged bottle caps, etc., can solve the problems of complex structure, short service life, and low reliability of performance, and achieve the effects of simple installation and operation, long service life and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

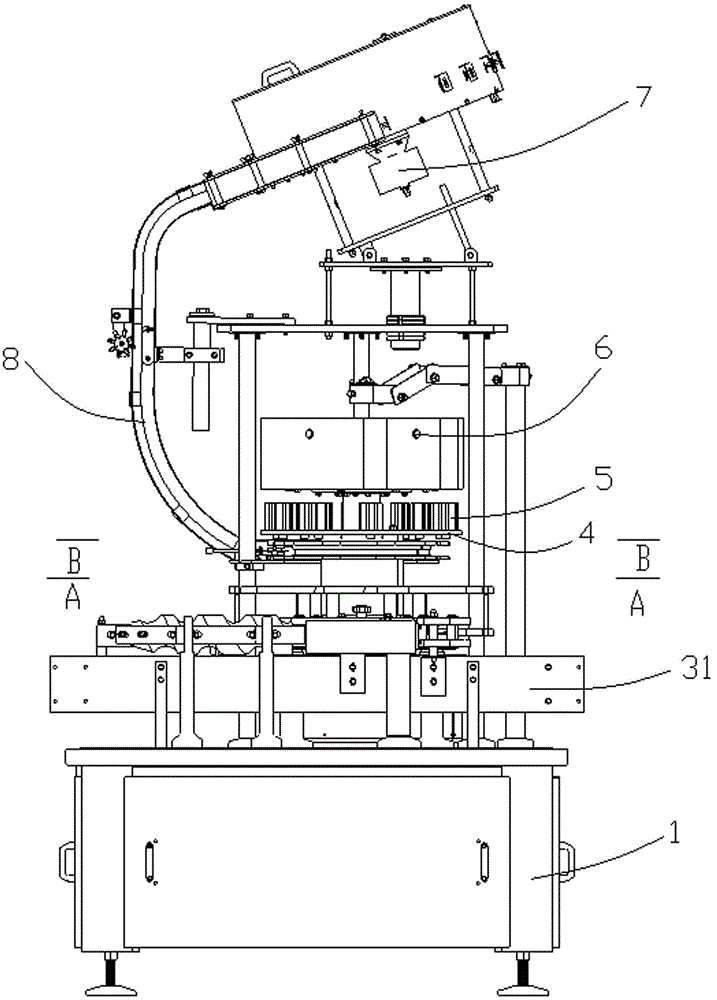

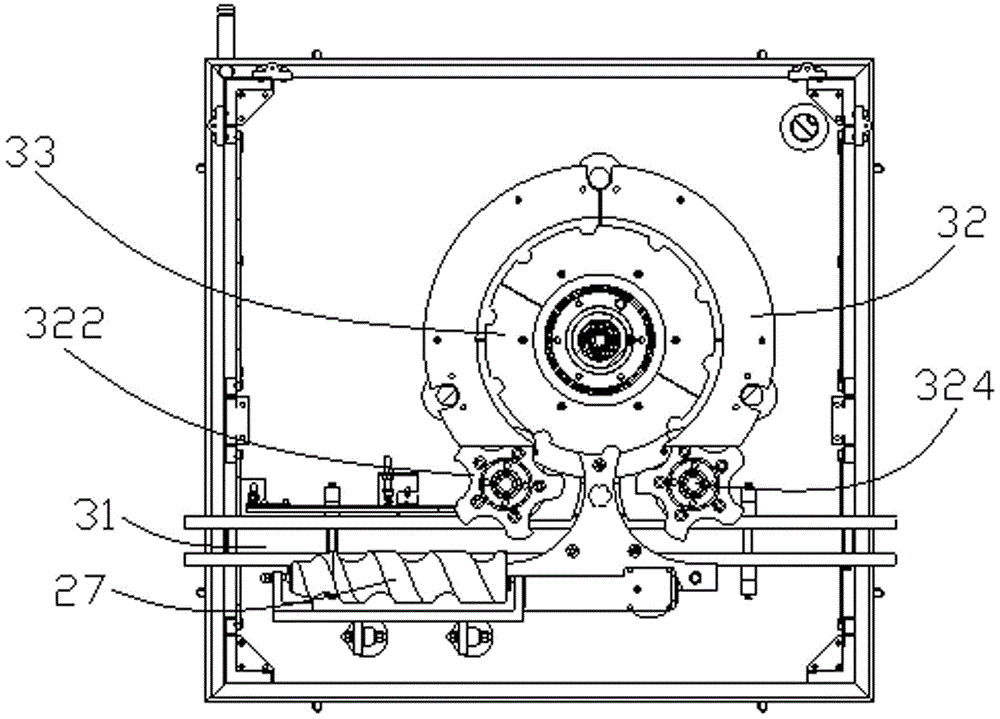

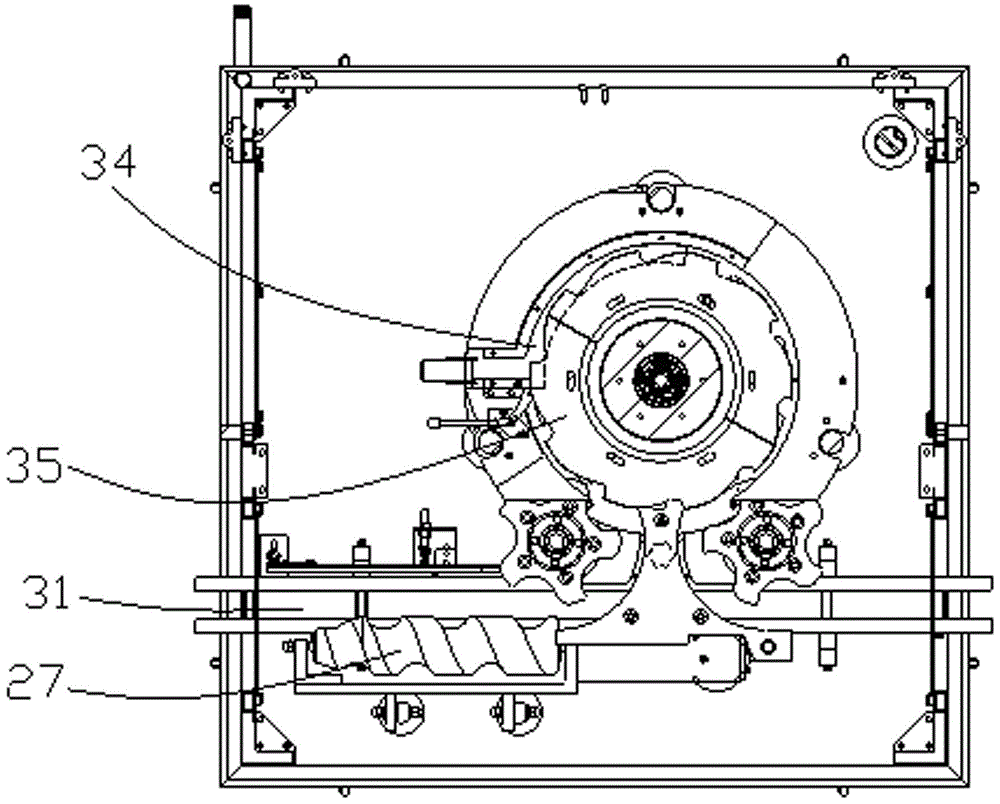

[0031] see Figure 1 to Figure 3 , the plastic bottle cap capping machine of the present invention comprises a frame 1, a drive assembly 2 located at the bottom of the frame 1 (see Figure 4 ) and a bottle cap positioning assembly set on the frame 1 and driven by the drive assembly 2, the bottle cap positioning assembly includes a conveyor belt 31 set on the frame 1 for conveying bottles, a set On one side of the conveyor belt 31, a bottle supporting rotary plate 32 for positioning the bottle body, a central positioning plate 33, a bottle cap tray 34 and a cap shifting plate set coaxially and sequentially on the bottle supporting rotary plate 32 35. The capping disc 35 is provided with a capping rotary disc 4, and the capping rotary disc 4 is provided with a plurality of capping head devices 5 for pressing bottle caps. A central control box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com