Saline alkali soil conditioner

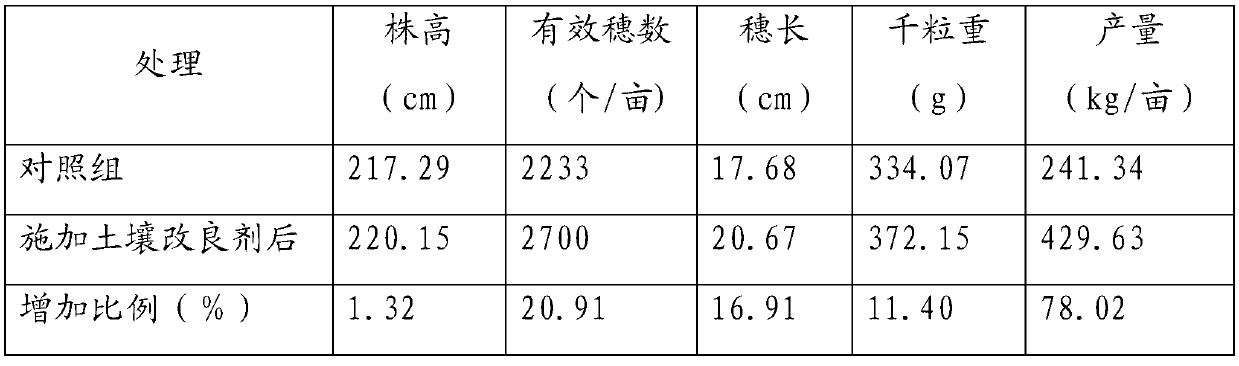

A technology of saline-alkali soil and improver, applied in soil conditioning materials, organic fertilizers, fertilizer mixtures, etc., can solve the problems of affecting the absorption of nutrients, bringing in toxic and harmful heavy metals, and bringing in bacteria, etc., and achieves the improvement of saline-alkali soil, The effect of solving waste disposal problems and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. The raw material phosphogypsum, decomposed sawdust, decomposed distiller's grains and phosphate rock slag are respectively pulverized and passed through a 2mm sieve;

[0017] 2. Weigh 5KG of phosphogypsum, 10KG of weathered coal, 35KG of decomposed sawdust, 25KG of fulvic acid, 20KG of decomposed distiller's grains, 5KG of phosphate slag, and 0.01KG of rooting agent;

[0018] 3. Mix the above raw materials evenly, and it is ready. It can be made into powder, granule or stick according to different requirements.

Embodiment 2

[0020] 1. The raw material phosphogypsum, decomposed sawdust, decomposed distiller's grains and phosphate rock slag are respectively pulverized and passed through a 2mm sieve;

[0021] 2. Weigh 10KG of phosphogypsum, 8KG of weathered coal, 40KG of decomposed sawdust, 20KG of fulvic acid, 30KG of decomposed distiller's grains, 8KG of phosphate slag, and 0.05KG of rooting agent;

[0022] 3. Mix the above raw materials evenly, and it is ready. It can be made into powder, granule or stick according to different requirements.

Embodiment 3

[0024] 1. The raw material phosphogypsum, decomposed sawdust, decomposed distiller's grains and phosphate rock slag are respectively pulverized and passed through a 2mm sieve;

[0025] 2. Weigh 8KG of phosphogypsum, 5KG of weathered coal, 30KG of decomposed sawdust, 15KG of fulvic acid, 35KG of decomposed distiller's grains, 10KG of phosphate slag, and 0.03KG of rooting agent;

[0026] 3. Mix the above raw materials evenly, and it is ready. It can be made into powder, granule or stick according to different requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com