High-speed railway track static comfort analysis adjustment method

A technology of static smoothness, high-speed railway, applied in the direction of track, track laying, track maintenance, etc., it can solve the problems of systematic analysis and adjustment of the overall smoothness and smoothness of the track, heavy workload, difficult to achieve, etc., to achieve true measurement results, Highly targeted and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

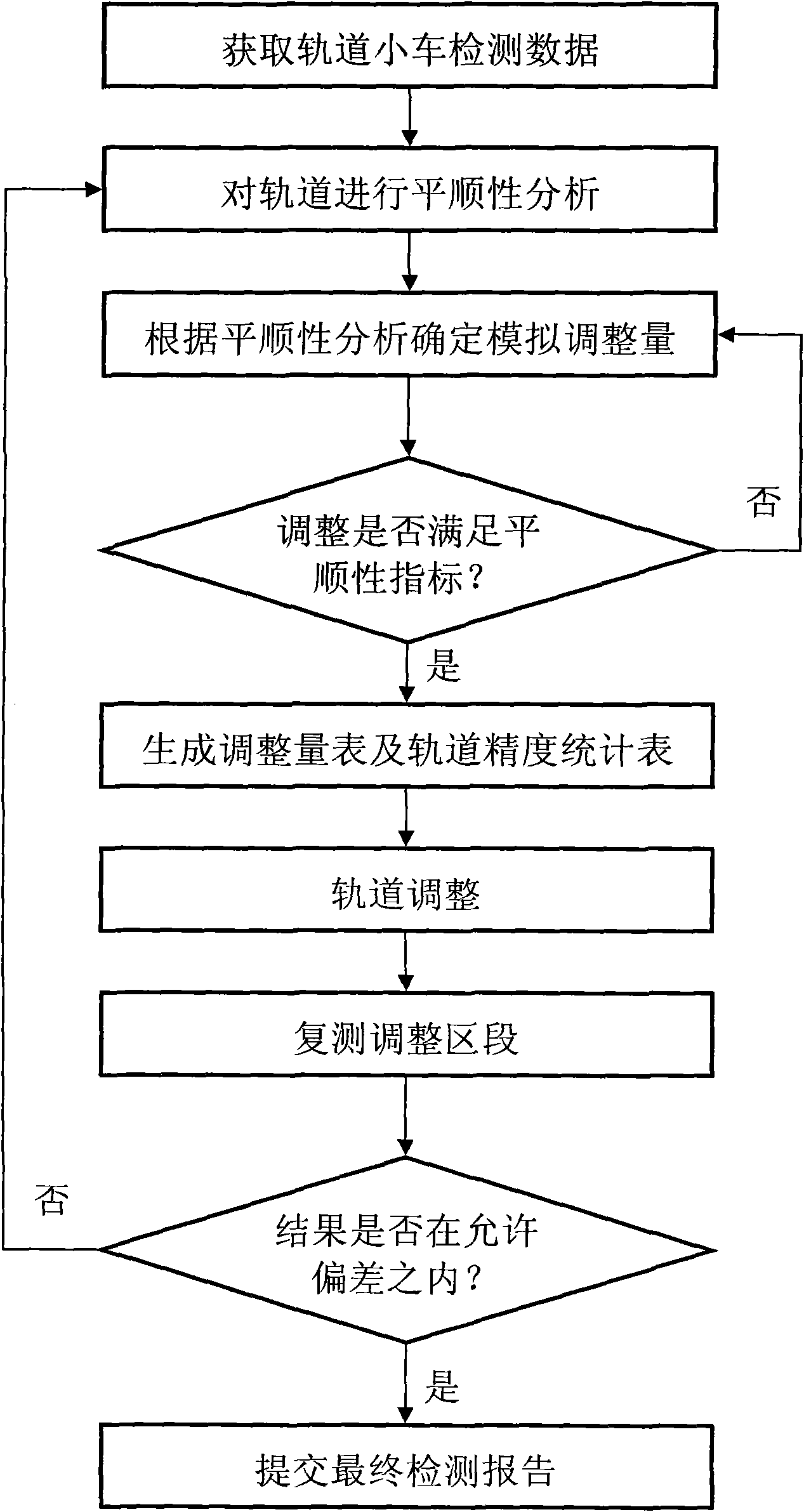

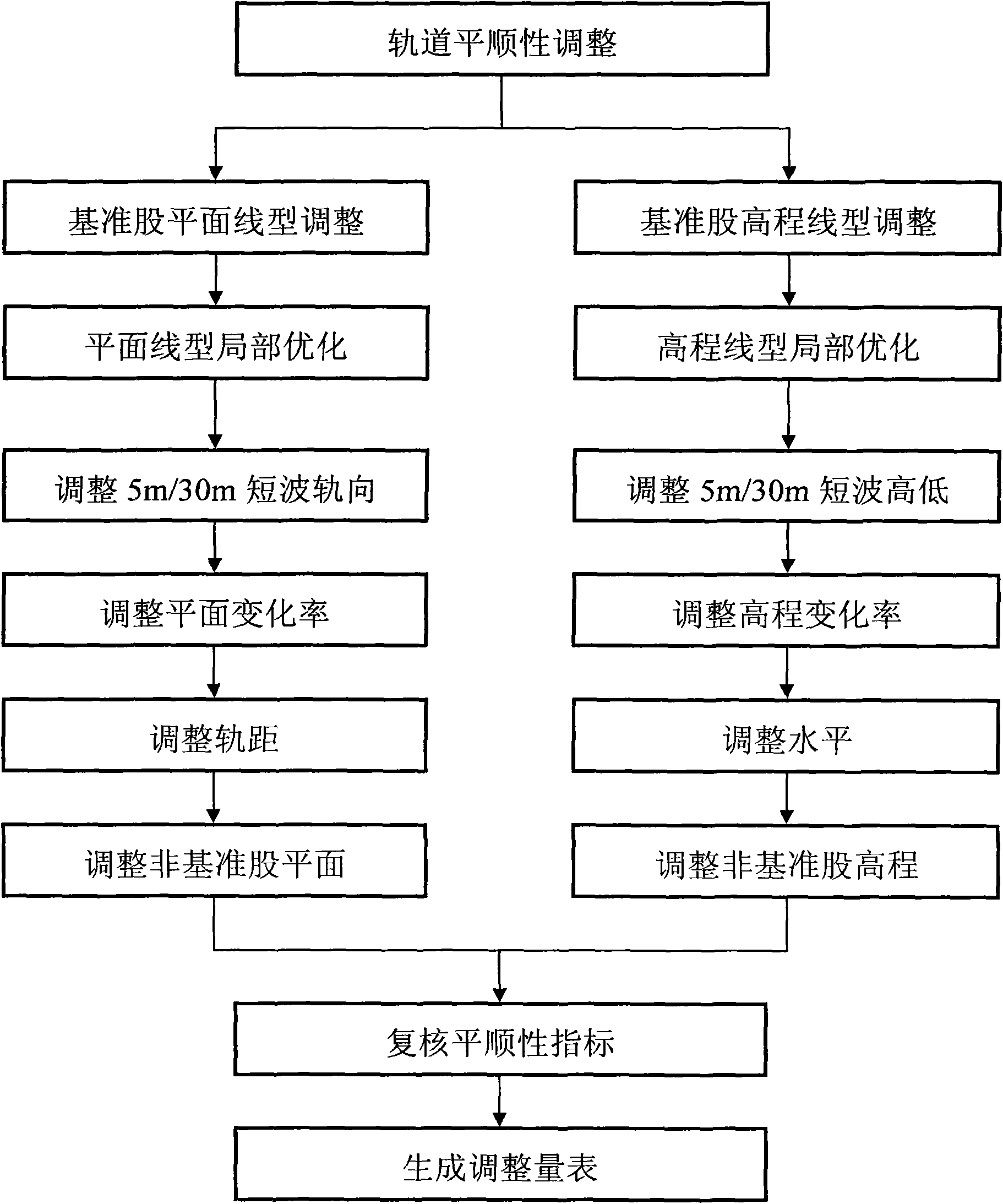

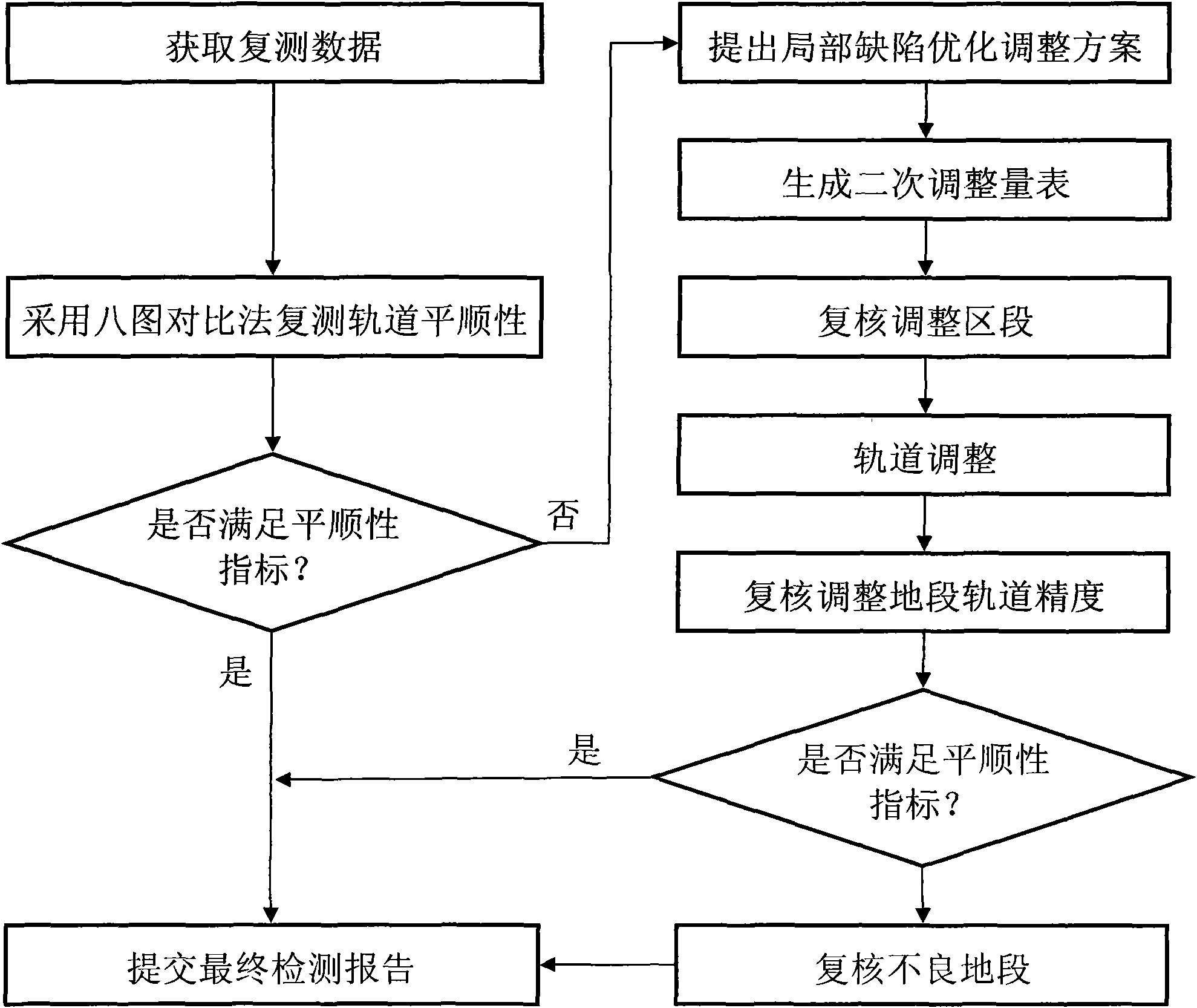

Method used

Image

Examples

Embodiment Construction

[0055] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0056] The rail trolley measurement technology used in the embodiment of the present invention can realize accurate measurement of railway tracks, and has been widely used in railway track measurement at present.

[0057] The absolute accuracy of the track is a measure of the deviation between the actual geometric shape of the track and the design theoretical shape, specifically the deviation between the measured center line and elevation of the track and the design theoretical center line and elevation. The relative accuracy of the track refers to the relative accuracy between the rails, and its main parameters include rail direction, height, gauge, level, etc.

[0058] The CPIII pile control network is a three-dimensional contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com