A three-component induction coil system probe wire passing structure

An induction coil and three-component technology, which is applied in the directions of measurement, borehole/well components, earthwork drilling and production, etc., can solve the problems that affect the detection of weak signals, the signal passing through the line is prone to interference, and cannot meet the needs of large borehole logging, etc. Achieve the effects of good weak signal detection ability, reliable work, and enhanced awareness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

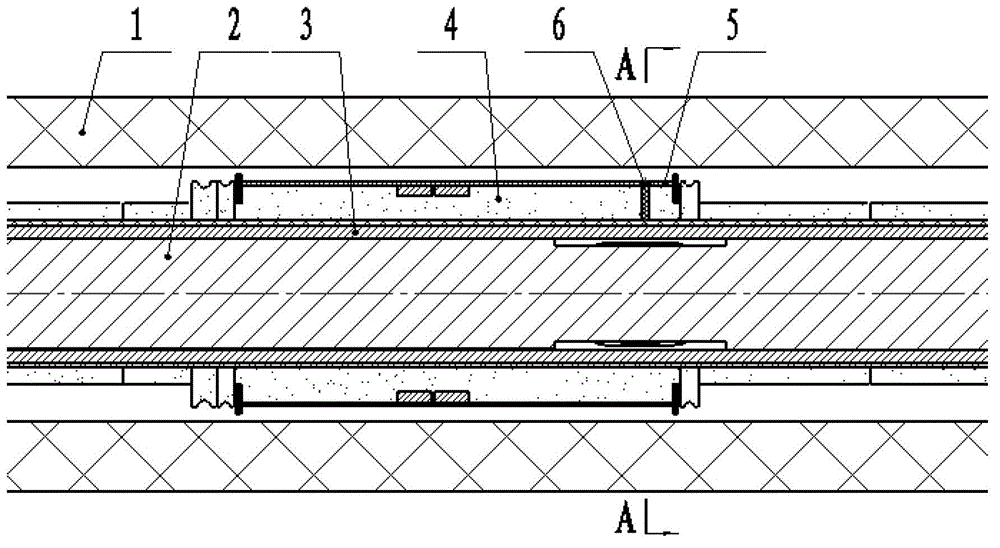

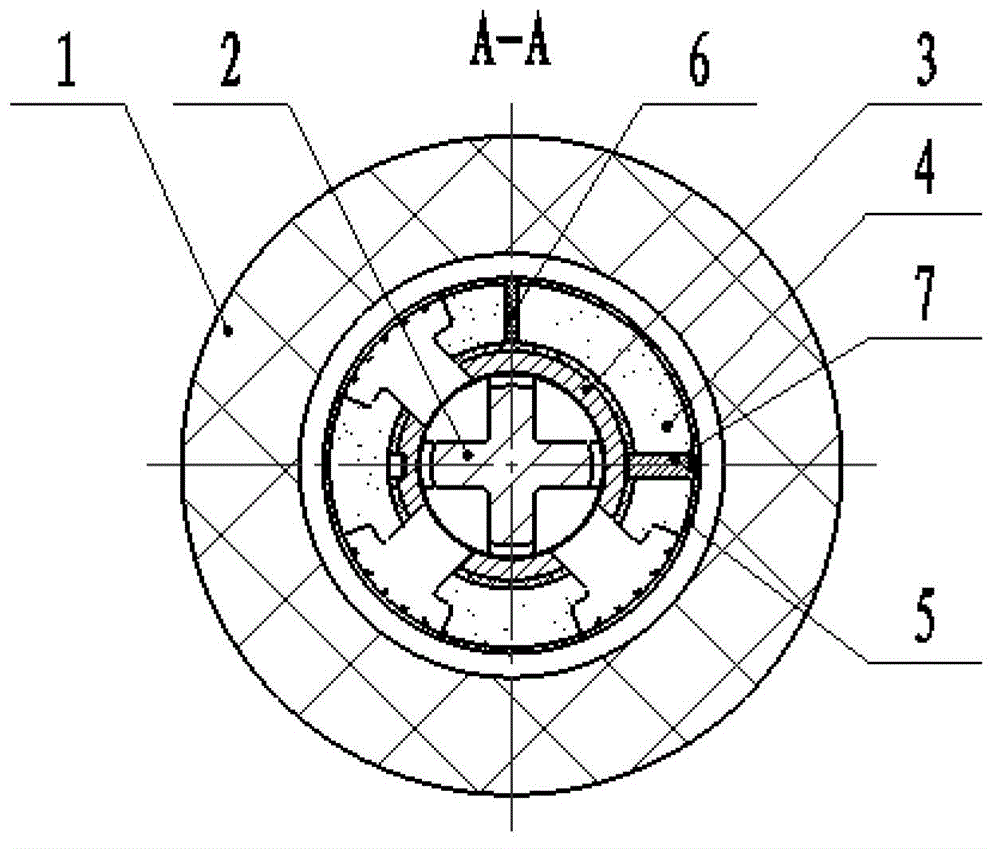

[0025] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

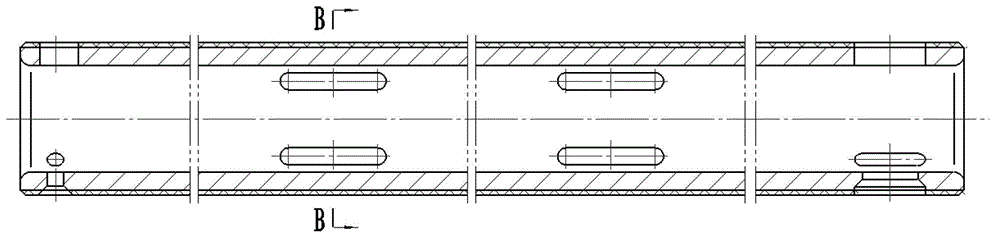

[0026] The three-component induction coil system probe wire passing structure provided by the present invention is composed of a non-magnetic pressure-bearing shell 1, a metal mandrel 2, a composite copper tube 3, a Z coil skeleton 4, and an XY coil flexible plate 5.

[0027] Such as figure 1 and figure 2 As shown, the three-component coil system in the present invention selects the non-magnetic pressure-bearing shell 1, which has sufficient strength, reliable sealing and good insulation, and the metal mandrel 2 is designed as a slender shaft according to the installation requirements of the three-component coil system Structure, its cross-section is a cross-shaped structure, which is convenient for the independent wiring of the X, Y, and Z directions of the coil system and the outgoing coil of the transmitting coil.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com