Shield ground compartment opening method

A ground and shield technology, applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of low safety factor, large body injury, casualties, etc., to ensure safety, prevent water and soil influx, and save construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

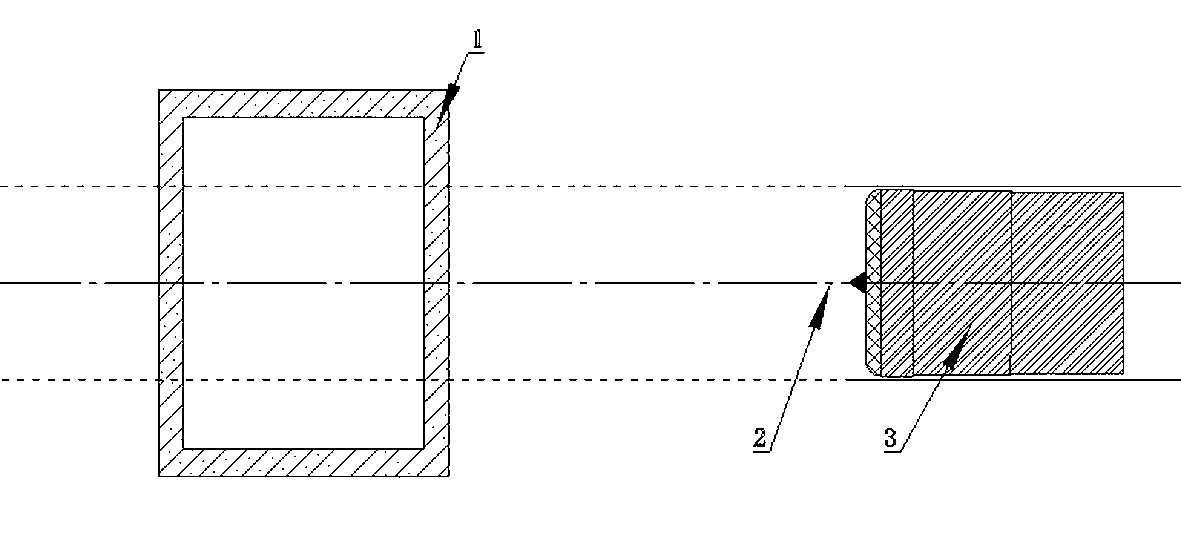

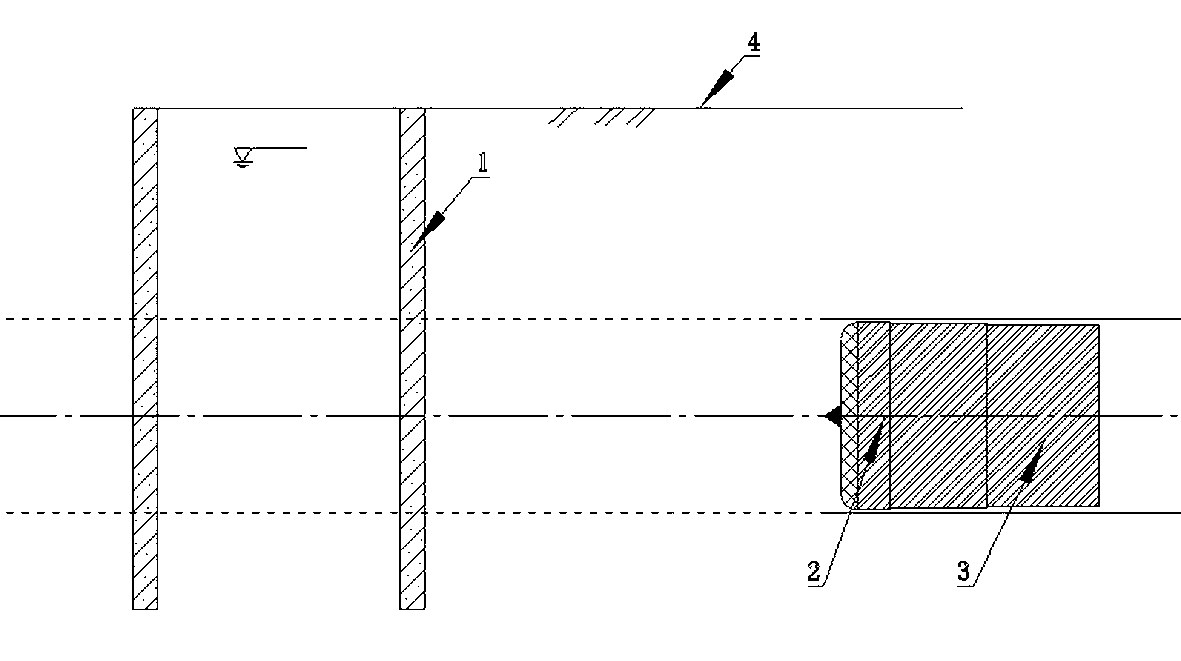

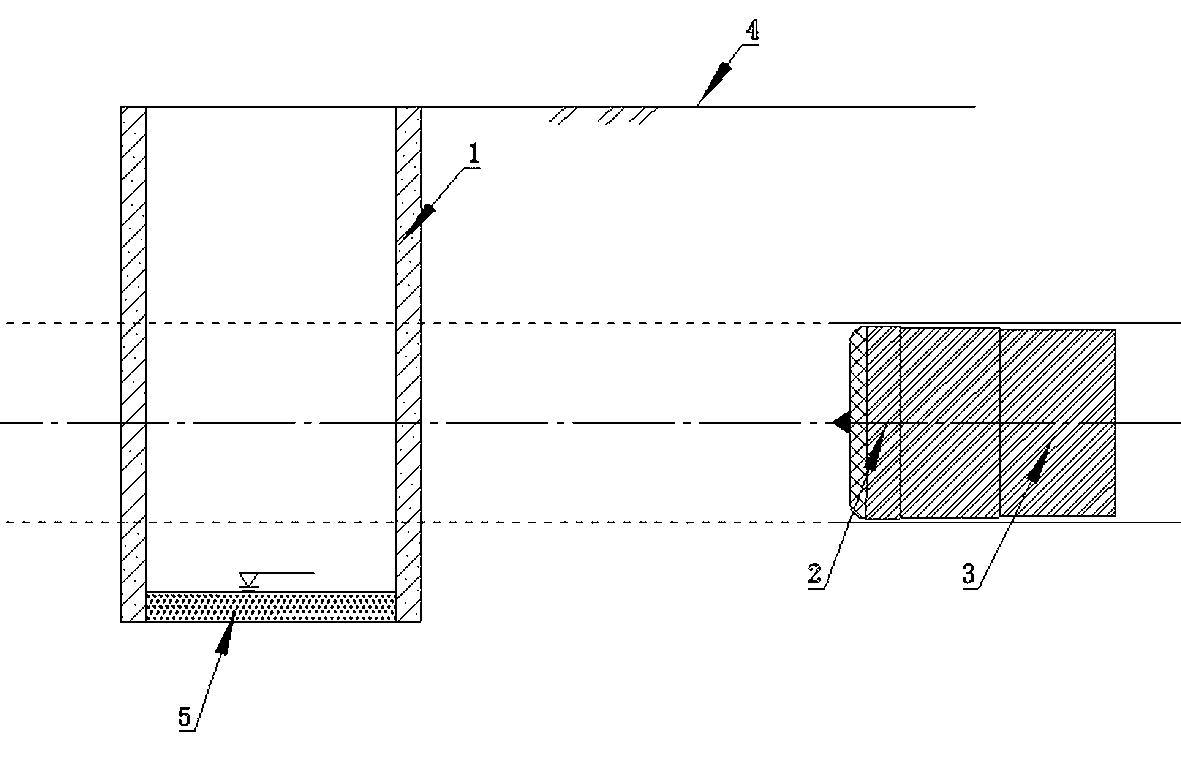

[0025] The specific embodiments of the present invention will be further described with reference to the drawings.

[0026] Shield ground opening method, the steps are as follows:

[0027] (1) For the construction stratum, pre-calculate the wear amount of the cutter head and the position where the tool needs to be changed, that is, the preset position of the warehouse;

[0028] (2) Use mixing piles or jet grouting piles in advance at the preset opening position to construct the outer wall according to the set opening outer wall size;

[0029] (3) Use double-liquid grouting to seal the bottom to form a box with an open upper end, and pump groundwater from the box formed by mixing piles and grouting;

[0030] (4) The shield continues to advance through the wall formed by the mixing pile, and the head enters the box formed by the mixing pile and grouting, and the gap between the shield and the wall is blocked by grouting with the advance grouting hole of the shield;

[0031] (5) Use a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com