Self-suction centrifugal pump

A self-priming centrifugal pump and pump body technology, applied in the field of water pumps, can solve problems such as limited use, and achieve the effects of large water supply, convenient operation, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

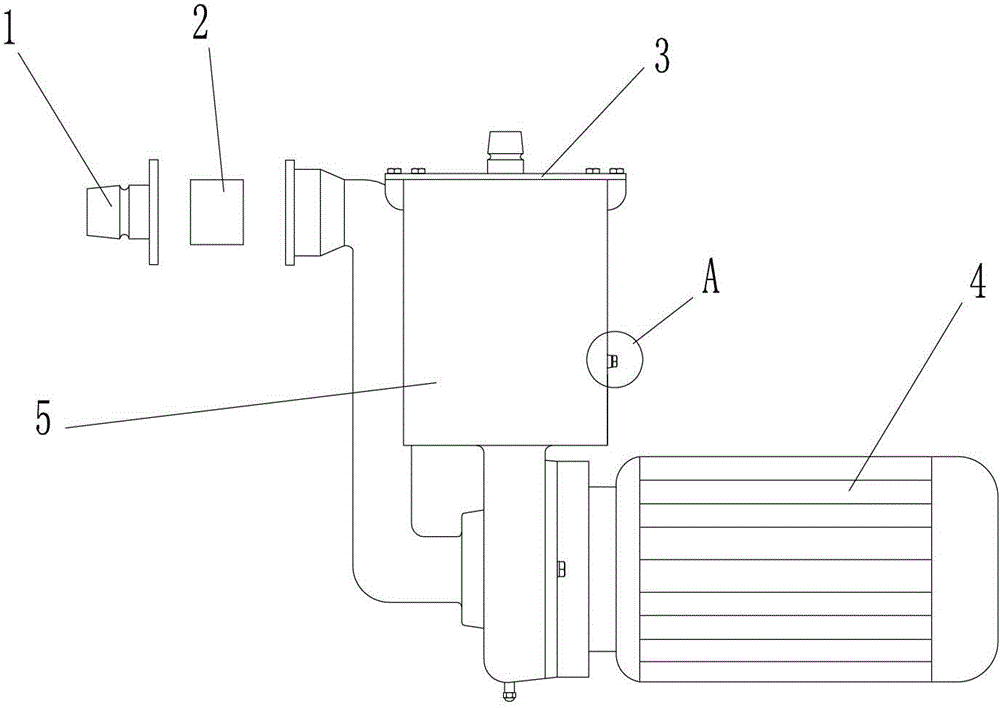

[0022] See figure 1 , the present invention comprises a pump body 5 and a motor 4, and an impeller is installed on the motor shaft of the motor 4.

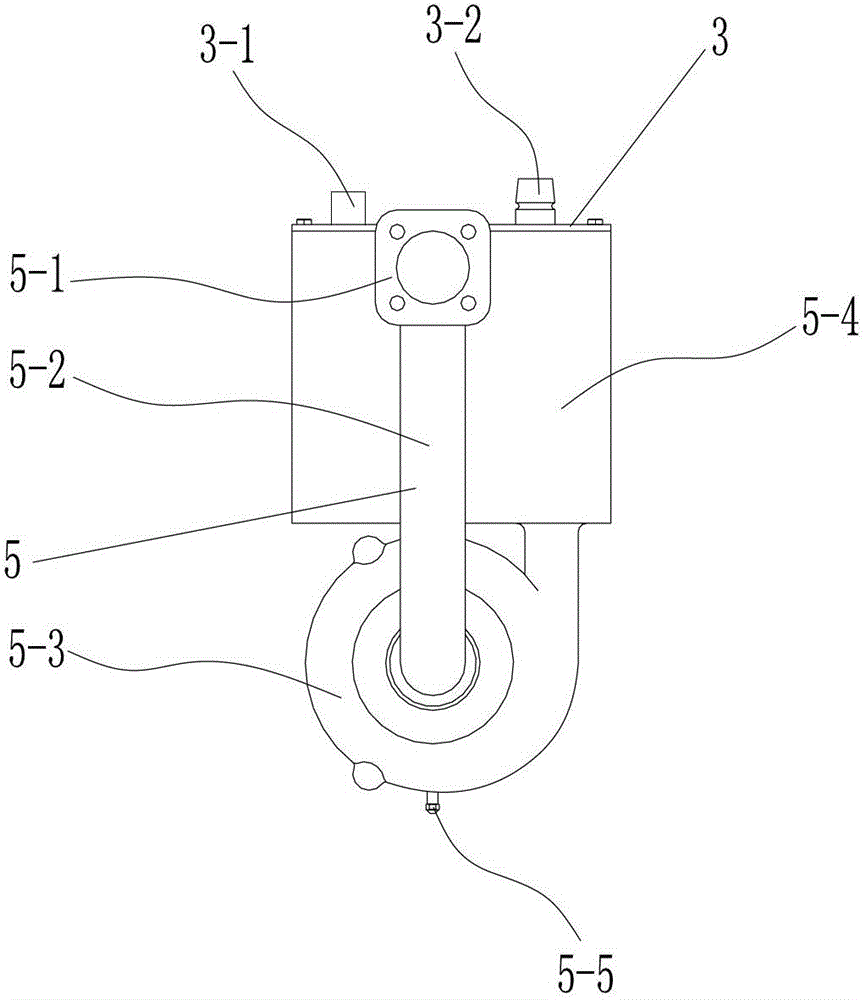

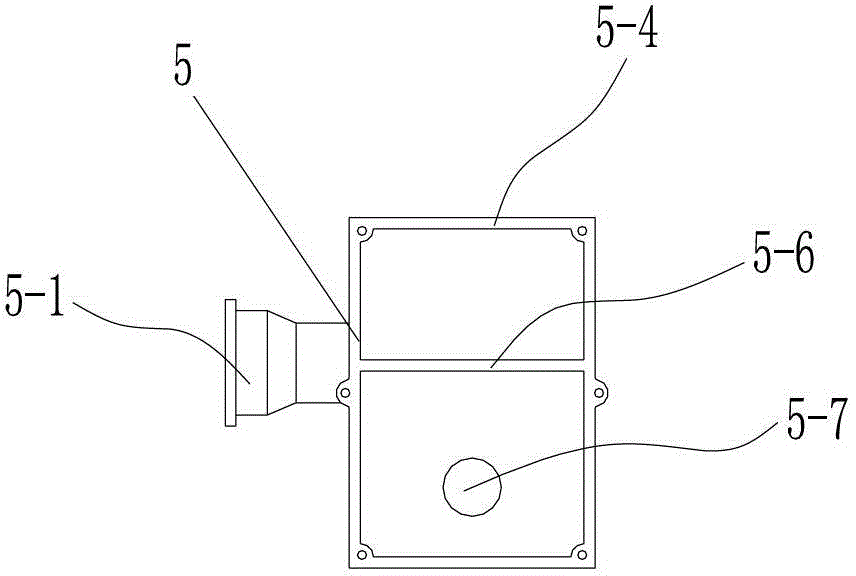

[0023] figure 2 and image 3 The specific structure of the pump body 5 is shown. The pump body 5 includes a water inlet channel 5-2, a volute 5-3 and a water tank 5-4, wherein the volute 5-3 is fastened to the motor disc of the motor 4, and the impeller is located inside the volute 5-3 to provide centrifugal force. In order to improve the overall compactness and firmness of the pump body 5, the water inlet channel 5-2, the volute 5-3 and the water tank 5-4 are integrally cast and formed.

[0024] Water tank 5-4 is rectangular body shape. The volute 5-3 is positioned directly below the water tank 5-4, and its outlet is connected with the upper no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com