Infrared camera

An infrared and camera technology, applied to cameras, camera bodies, TVs, etc., can solve problems such as messy signals, image resolution effects, highlighting fixed graphics, etc., achieve good shooting, suppress temperature changes, and reduce the impact of temperature changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

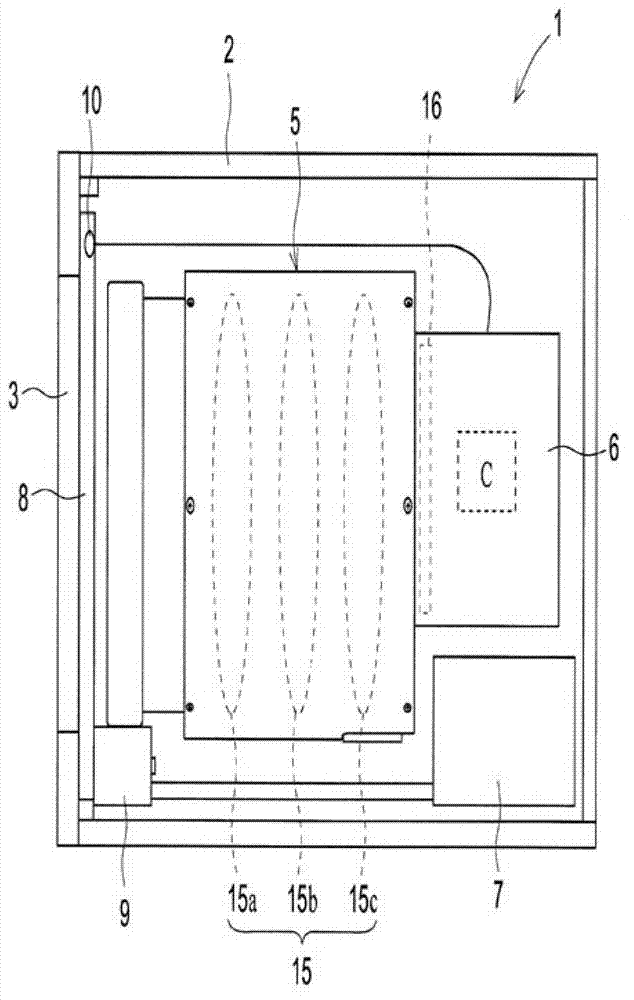

[0026] Structure of the infrared camera: First, regarding the structure of the infrared camera of the first embodiment, use figure 1 Be explained. figure 1 It is a diagram schematically showing the internal structure of the infrared camera according to the first embodiment of the present invention. Such as figure 1 As shown, the infrared camera 1 of the present invention is configured by arranging an infrared lens unit 5 , a camera body 6 , a power supply board (power supply) 7 and the like in a housing 2 of the infrared camera 1 .

[0027] Housing 2 forms the outer contour of infrared camera 1 . The casing 2 has a substantially cylindrical shape. Furthermore, the inside of the casing 2 is constituted as a closed space. Further, on the subject side of the casing 2 , a window portion 3 is formed at a portion of the infrared lens unit 5 facing the subject side of the infrared lens group 15 .

[0028] The window portion 3 is made of a material that transmits infrared rays. ...

no. 2 approach

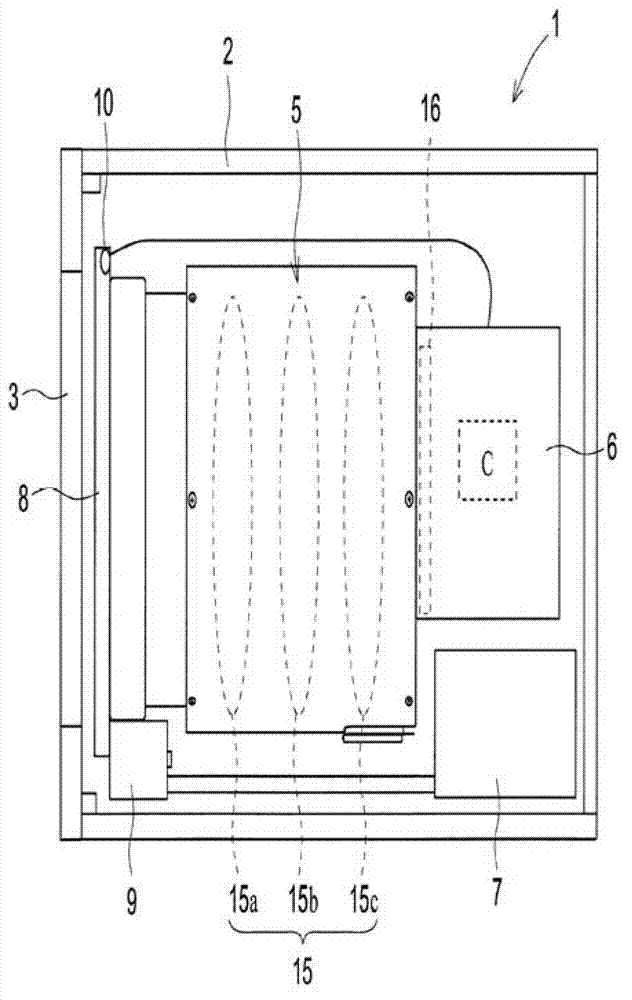

[0052] figure 2 It is a figure which schematically shows the infrared camera of 2nd Embodiment. In the infrared camera 1 according to the second embodiment, the shutter 8 is provided on the side closest to the subject of the infrared lens group 15 . In the infrared camera 1 of this embodiment, as figure 2 As shown, the shutter 8 is located on the subject side of the infrared lens 15a of the infrared lens group 15, and is provided at a position closest to the infrared lens 15a.

[0053] in addition, figure 2 Compared with the infrared camera 1 of the first embodiment described above, only the position of the shutter 8 is different, and other configurations and operations are the same as those described above. Therefore, descriptions of the same configurations and operations are omitted.

[0054] figure 2 The shown shutter 8 may be mounted on the infrared lens unit 5 in addition to being mounted on the inner wall of the casing 2 as in the infrared camera 1 of the first ...

no. 3 approach

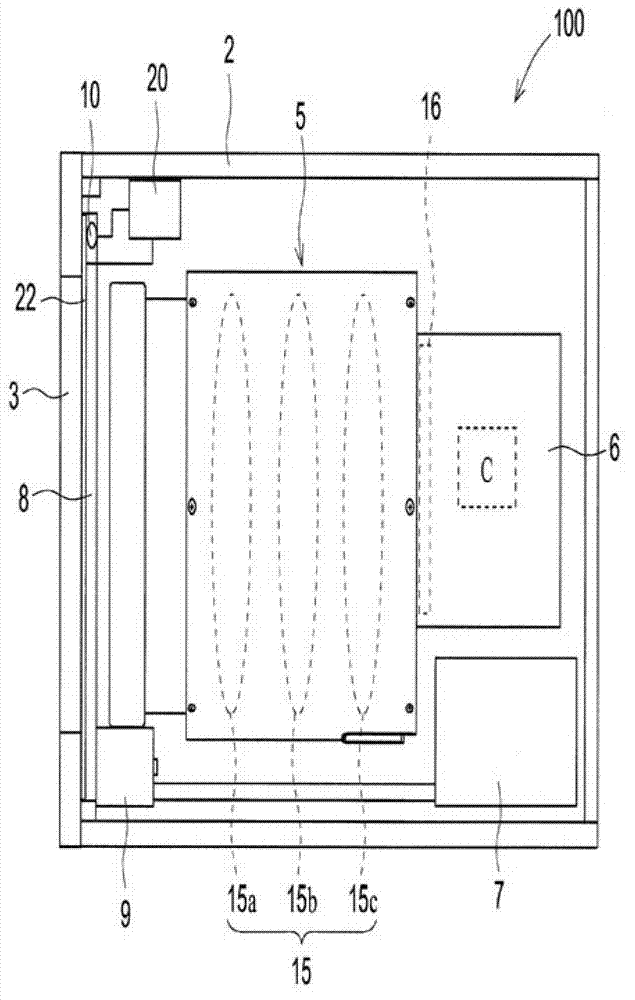

[0057] Next, for the infrared camera of the third embodiment, refer to image 3 Be explained. In addition, in image 3 Among them, the parts given the same reference numerals as those of the infrared camera 1 according to the first embodiment achieve the same or similar effect or function, and therefore description thereof will be omitted here.

[0058] Configuration of Infrared Camera: First, the configuration of the infrared camera according to the third embodiment will be described. Such as image 3 As shown, the infrared camera 100 of the present invention is an infrared camera configured by housing an infrared lens unit 5 , a camera body 6 , a power supply board 7 , etc. in a housing 2 of the infrared camera 100 . The inside of the casing 2 constituting the outer contour of the infrared camera 100 is formed as a closed space.

[0059] The camera body 6 has a control device C that controls the infrared camera 100 . The control device C has a function of compensating and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com