Constant current driving device of light-emitting diode (LED) backlight module

A technology of constant current drive and backlight module, applied in instruments, static indicators, etc., can solve the problems of low overall circuit efficiency, complex power system, energy loss, etc., and achieve the effect of low cost, high efficiency and simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described below with reference to the accompanying drawings.

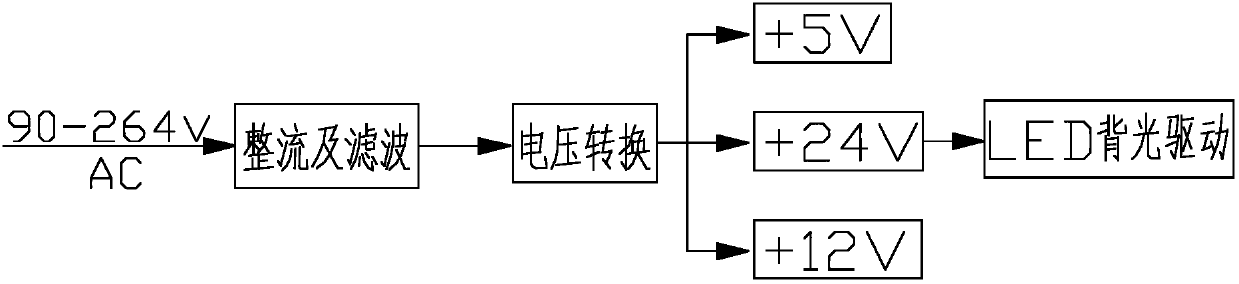

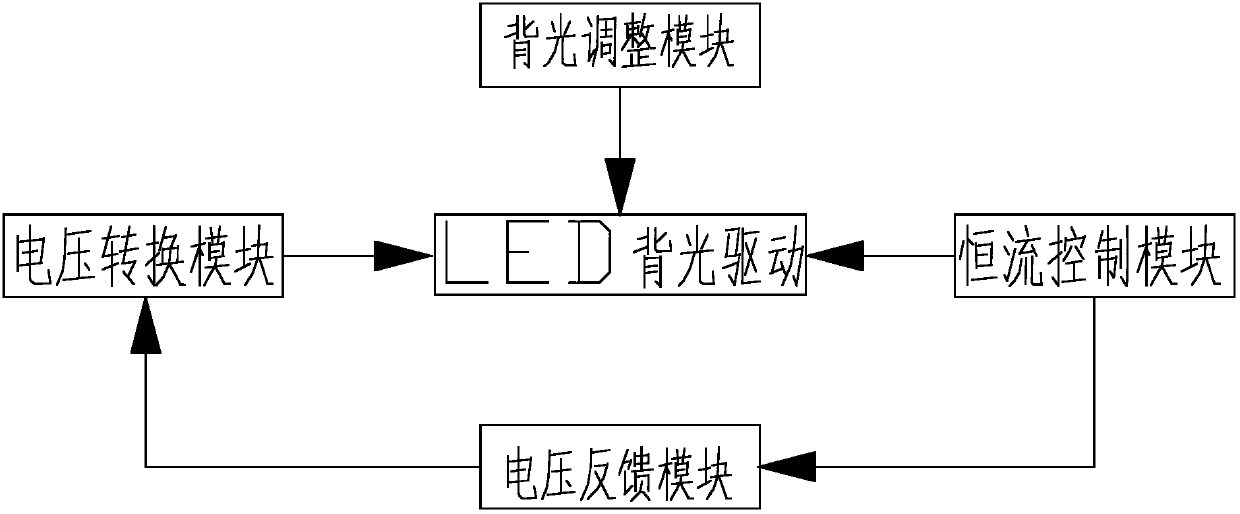

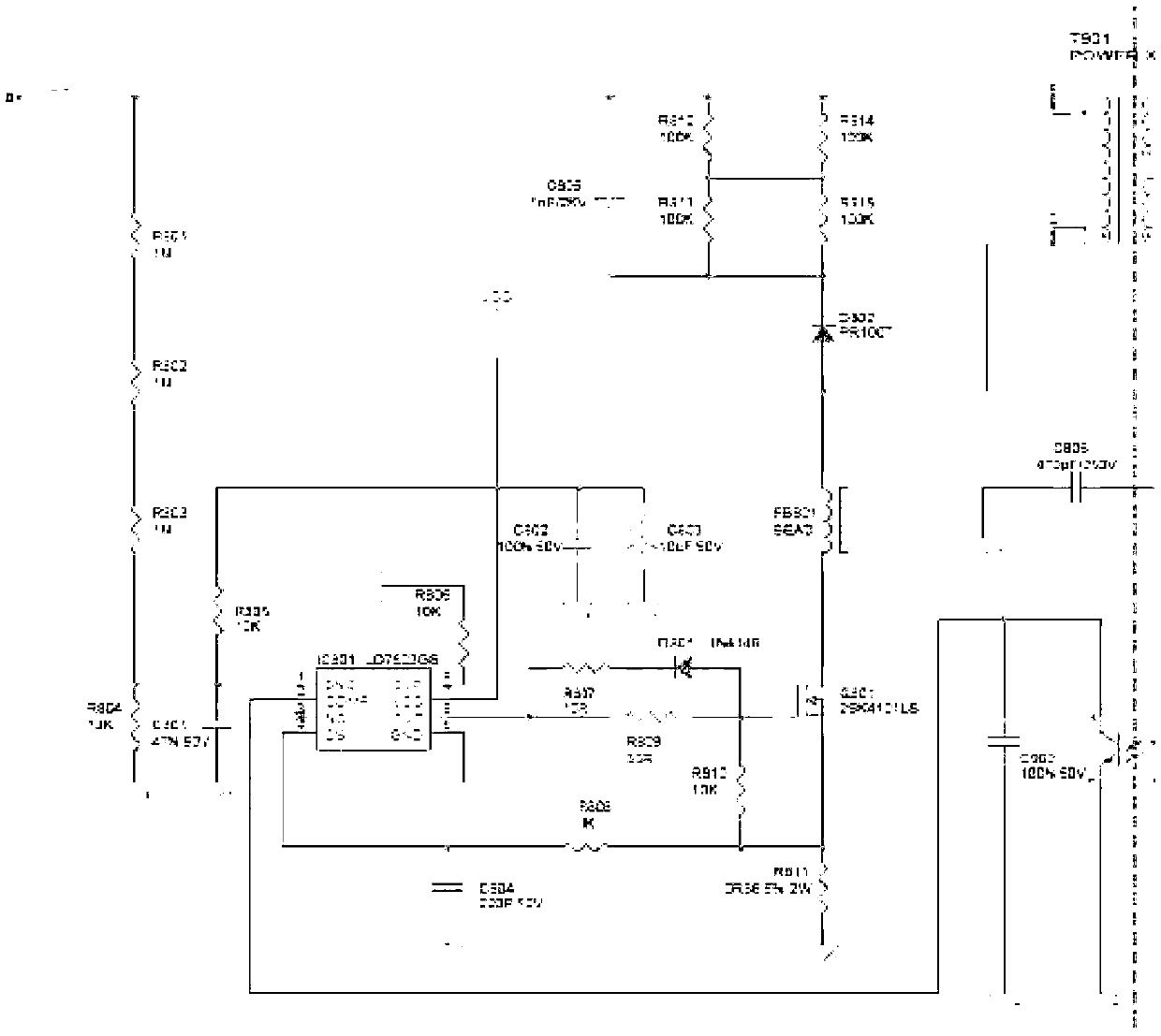

[0018] as attached Figure 2-7 The constant current driving device of the LED backlight module of the present invention includes a voltage conversion module, a voltage feedback module, a backlight adjustment module and a constant current control module; the voltage conversion module generates a DC voltage through a flyback topology structure, And the DC voltage is used to drive the LED backlight to light up the LED light bar; the constant current control module controls the current flowing through the LED light bar driven by the LED backlight by controlling the on-off of the MOS tube, so that the current does not exceed the LED light bar. The maximum current that can be endured; the voltage feedback module realizes the control of the output voltage of the voltage conversion module through negative feedback, so as to achieve the purpose of stabilizing the output voltage within a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com