Novel multilayer structure silicon carbide photoconductive switch and its preparation method

A photoconductive switch, multi-layer structure technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of no reduction in switch conduction characteristics, high breakdown voltage, small conduction current, etc., and reduce the mismatch rate. , The effect of improving breakdown voltage and improving withstand voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

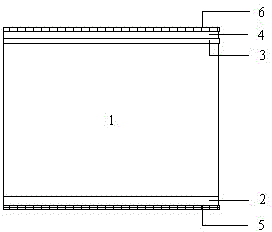

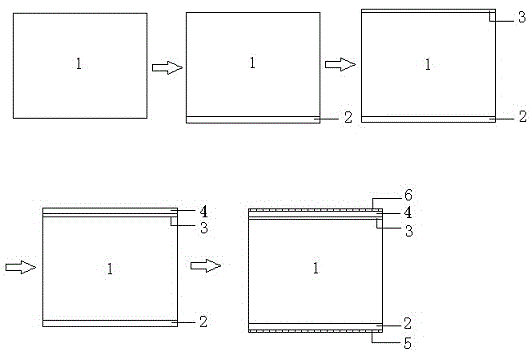

[0037] combine figure 1 , figure 2 , the preparation method of the novel multilayer structure silicon carbide photoconductive switch of the present embodiment, its steps are as follows:

[0038] 1) Select the substrate

[0039] A research-grade vanadium-doped silicon carbide wafer is selected as the substrate 1, and the thickness of the silicon carbide wafer is 300 mm;

[0040] 2) Epitaxial growth on the silicon surface of the substrate

[0041] Use high-temperature chemical vapor deposition (HTCVD) to epitaxially grow on the 0001 plane of the silicon surface of the substrate 1 at 4° off-axis and doped with electronic-grade purity nitrogen (N) to form the first doped layer 2 with a doping concentration of 5× 10 18 cm -3 , the growth temperature is 1580 ℃, the reaction gas flow rate is 20 mL / min of silane, 10 mL / min of propane, 20 mL / min of nitrogen, 80 L / min of carrier gas hydrogen, and the pressure is maintained at 50 mbar; the formed first doped layer 2 The thicknes...

Embodiment 2

[0050] combine figure 2 , the preparation method of the novel multilayer structure silicon carbide photoconductive switch of the present embodiment, its steps are:

[0051] 1) Select the substrate

[0052] A research-grade intrinsic silicon carbide wafer is selected as the substrate 1, and the thickness of the silicon carbide wafer is 330 mm;

[0053] 2) Epitaxial growth on the silicon surface of the substrate

[0054] Using high temperature chemical vapor deposition (HTCVD), on the 0001 plane of the silicon surface of the substrate 1, the off-axis 8° epitaxial growth is doped with electron-grade pure nitrogen (N) to form the first doped layer 2 with a doping concentration of 3×10 18 cm -3 , the growth temperature is 1500 ℃, the reaction gas is composed of silane, propane and nitrogen, the gas flow rate is 0.5 sccm, the carbon-to-silicon ratio (C / Si) is 2, the carrier gas hydrogen flow rate is 3000 sccm, and the reaction chamber pressure is 100 mbar. The thickness of the...

Embodiment 3

[0063] combine figure 2 , the preparation method of the novel multilayer structure silicon carbide photoconductive switch of the present embodiment, its steps are:

[0064] 1) Select the substrate

[0065] A research-grade vanadium-doped silicon carbide wafer is selected as the substrate 1, and the thickness of the silicon carbide wafer is 350 mm;

[0066] 2) Epitaxial growth on the silicon surface of the substrate

[0067] On the silicon surface of substrate 1, nitrogen (N) of electronic grade purity is epitaxially doped on the 0001 surface of the silicon surface of substrate 1 at an off-axis 8° by using a high-temperature chemical vapor deposition (HTCVD) process to form a 20 mm thick, doped The concentration is 2×10 18 cm -3 N-type first doped layer 2, the growth temperature is 1600 ℃, the reaction gas flow rate is 22 mL / min of silane, 13 mL / min of propane, 22 mL / min of nitrogen, 83 L / min of carrier gas hydrogen, and the pressure is maintained at 200 mbar ;

[0068]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com