segmented magnetic circuit

A magnetic circuit and section technology, applied in the direction of magnetic circuit, magnetic circuit shape/style/structure, manufacturing stator/rotor body, etc., can solve the problems of complex stacking of plates, difficulty in assembly and reconstruction, etc., and achieve good results Quality, connection and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

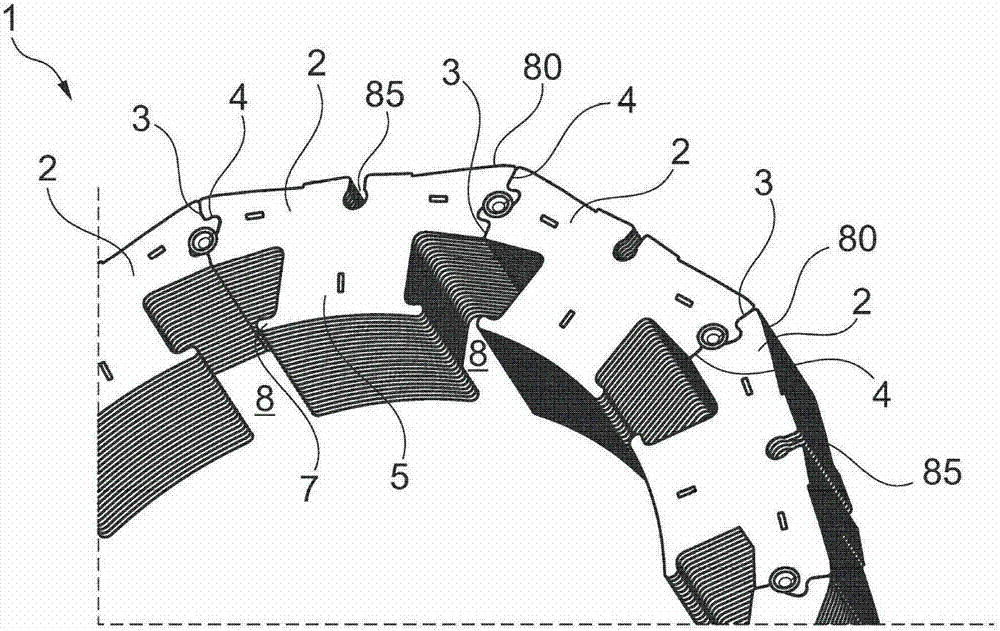

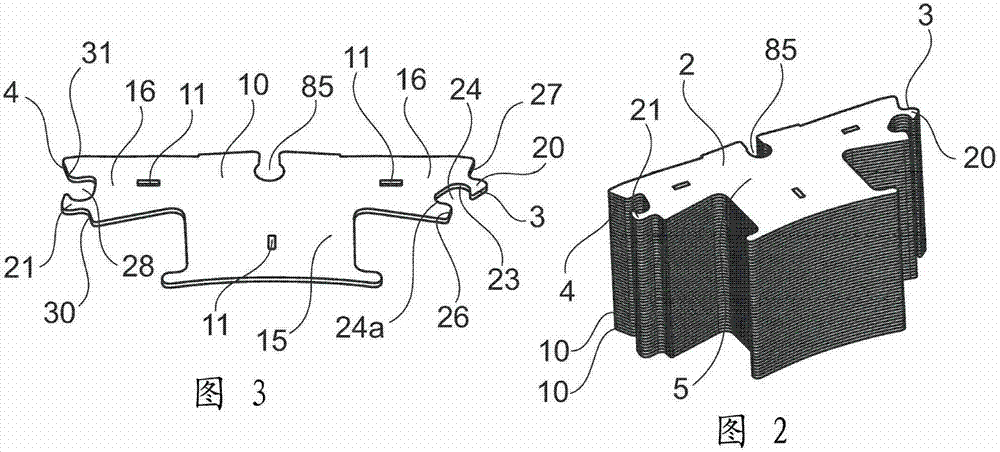

[0029] figure 1 The stator magnetic circuit 1 shown in , comprises a plurality of stacks 2 which are connected together at their flanks. Each stack 2 includes a tooth 5 of the magnetic circuit, which tooth is equipped with a pole shoe 7 in the example shown. As a variant, the tooth 5 does not have a pole piece. The magnetic circuit 1 defines between these teeth 5 notches 8 for receiving electrical conductors, not shown. Stators can have dense or distributed windings. As can be seen in FIG. 2 , each stack 2 is formed by stacking in sections identical magnetic plates 10 , one of these plates being represented in FIG. 3 . The panels 10 are connected together by mounting clips in the areas 11 in a conventional manner. Clamping areas 11 are located, for example, on the teeth 15 of each segment and on the annular yoke portion 16 intended to form a magnetic circuit behind the slot 8 .

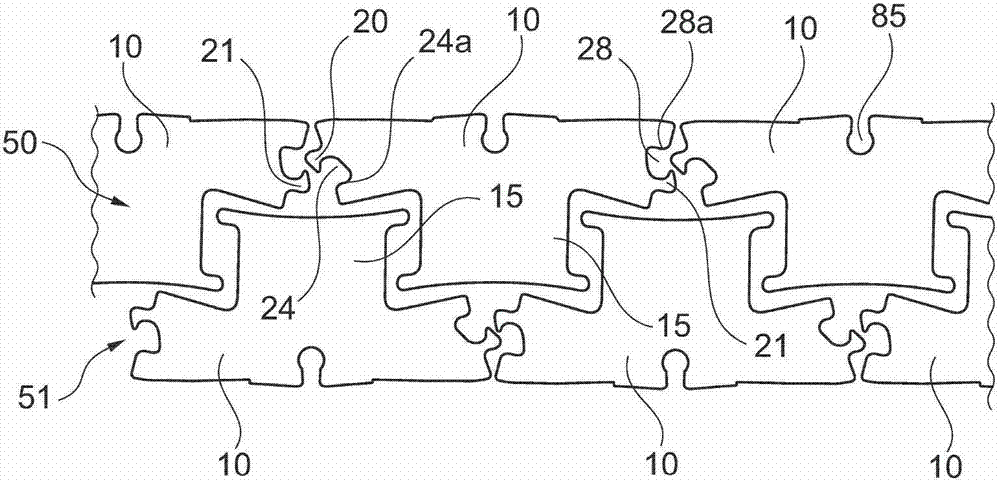

[0030] Ribs 20 and 21 are manufactured on the ends of these parts 16 , respectively on the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com