Modular large wall board, and manufacturing method and application thereof

A modular and board-based technology, applied to building structures, buildings, building components, etc., can solve the problems of poor stability of load-bearing walls, lack of utilization channels, air pollution, etc., to reduce construction waste, reduce weight, and save energy. The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

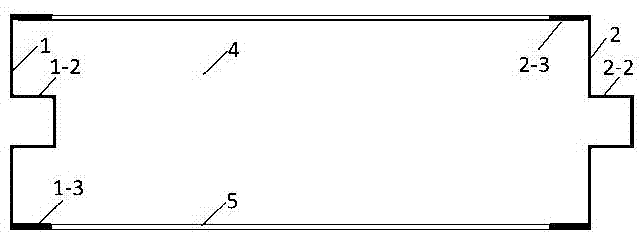

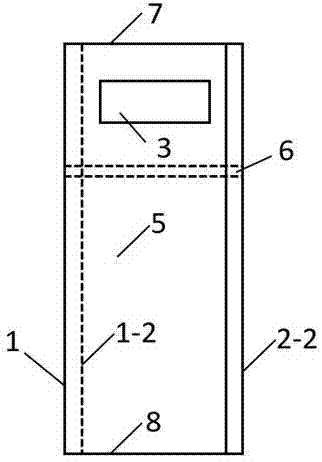

[0022] A modular large-scale wall panel, which includes a hoisting hole 6, a surface layer 5, a window frame 3, an insulation layer 4, and a first side strip 1, a second side strip 2, and a third side strip 7 with certain strength and elasticity and the fourth side strip 8; the surface layer 5 is a hard board such as cement board, the convex side strip includes the convex part 2-2, the side strip fixed side 2-3, and the concave side strip includes the concave part 1-2 and the side strip fixed side 1-3, the surface layer 5 and the insulation layer 4 are combined into one body through the first to fourth side strips.

[0023] The insulation layer 4 is made of reed stalks, cement, and cotton felt. The reed stalks and cement are integrated to form reed concrete. The cotton felt is attached to both sides of the reed concrete and connected with the adhesive layer; in the reed concrete, the reed stalks are laid layer by layer. Finally, a through hole perpendicular to the surface is p...

Embodiment 2

[0026] A modular large and small wall plate, including hoisting holes 6, surface layer 5, window frame 3, insulation layer 4 and first side strip 1, second side strip 2, third side strip 7 and The fourth side strip 8; the surface layer 5 is a hard board such as cement board, the convex side strip includes the convex part 2-2, the side strip fixed side 2-3, and the concave side strip includes the concave part 1-2 and the side strip fixed side 1 -3. The surface layer 5 and the insulation layer 4 are combined into one body through the first to fourth side strips.

[0027] Insulation layer 4 is made of corn stalks, cement, cotton felt, and corn stalks and cement are integrated to form straw concrete. The cotton felt is attached to both sides of the straw concrete and connected with the adhesive layer; in the straw concrete, the corn stalks are laid layer by layer Finally, a through hole perpendicular to the surface is provided in the formed corn stalk layer, and the through hole i...

Embodiment 3

[0030] A modular large-scale wall plate, the insulation layer 4 is made of wheat straw, cement, and cotton felt, and the wheat straw and cement are integrated to form wheat straw concrete. The cotton felt is attached to both sides of the wheat straw concrete and connected with the adhesive layer. In wheat stalk concrete, after the wheat stalk layer is laid, a through hole perpendicular to the surface is set in the formed wheat stalk layer, and the through hole is used to pass the concrete after the wheat stalk concrete is formed, and After solidification, a cylinder is formed, and the end surface of the cylinder is in contact with the cotton felt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com