Roll shaft

A technology of roller shaft and anti-corrosion layer, which is applied in the field of printing equipment parts, can solve the problems of strong corrosion, time-consuming and labor-intensive, scratching of plates, etc., and achieve the effects of strong corrosion resistance, increased washing quality, and increased washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

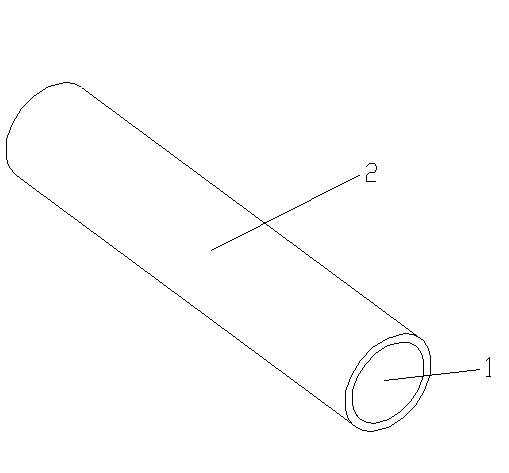

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 Shown is a roll shaft according to the present invention, including a roll shaft body 1, and an anti-corrosion layer 2 is provided outside the roll shaft body 1; the anti-corrosion layer 2 is a carbon fiber layer; the anti-corrosion layer 2 is PTFE layer.

[0014] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0015] The roller shaft of the present invention has an anti-corrosion layer on the outside of the roller shaft body, which has strong corrosion resistance, avoids the surface crystallization of the roller shaft, and improves the washing quality of the plate, so that the roller shaft does not need to be taken out frequently for cleaning and maintenance, saving time and effort. In turn, the washing efficiency of the plate is increased.

[0016] The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com