Novel steel wire mesh flanging machine

A technology of steel wire mesh and hemming machine, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of affecting appearance and production safety, restricting the rapid development of the textile industry, affecting the effect of textile fabrics, etc., and achieves simple structure, high impact The effect of low force and high production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Structure and working process of the present invention will be further described below in conjunction with accompanying drawing and embodiment:

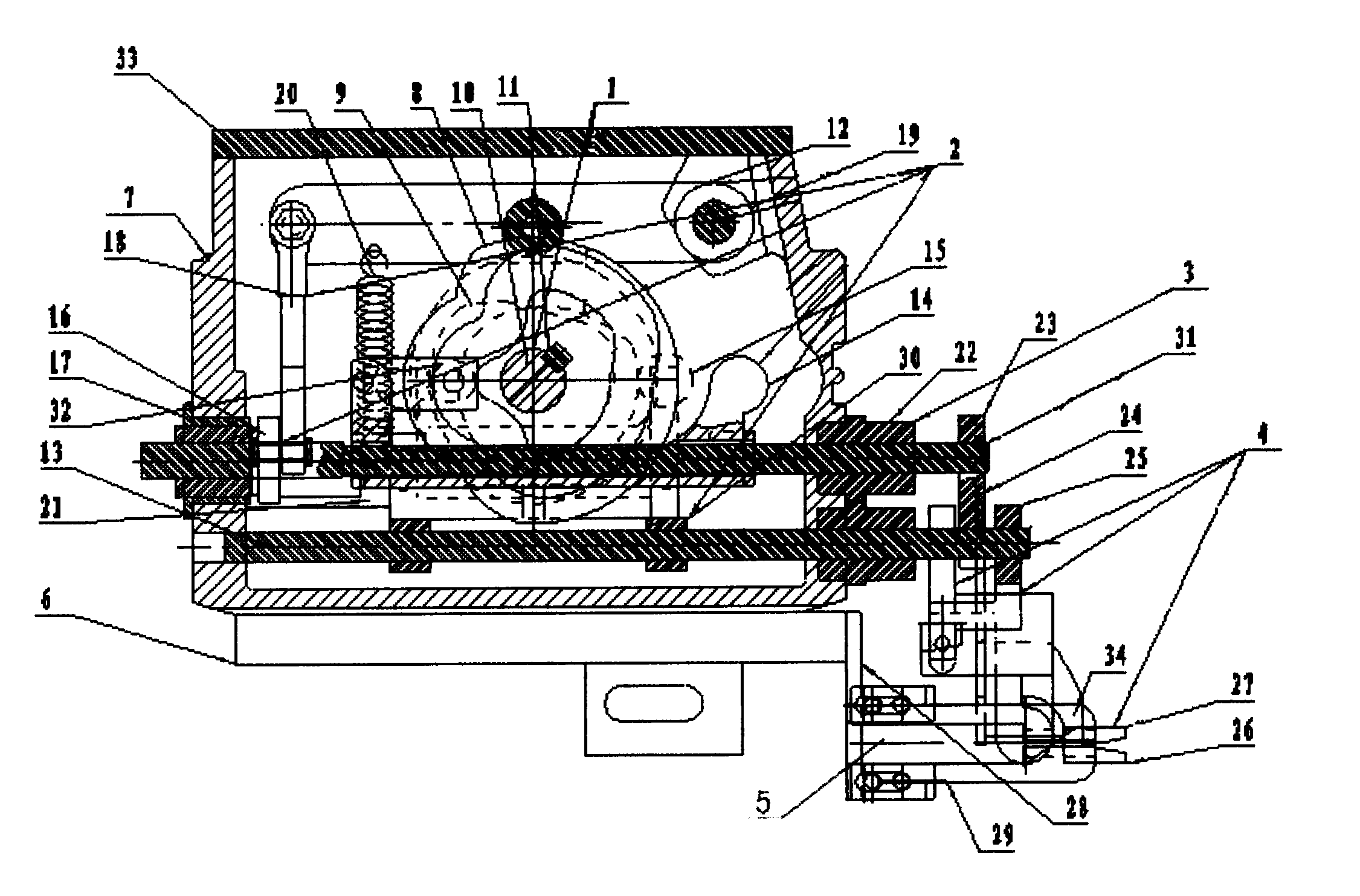

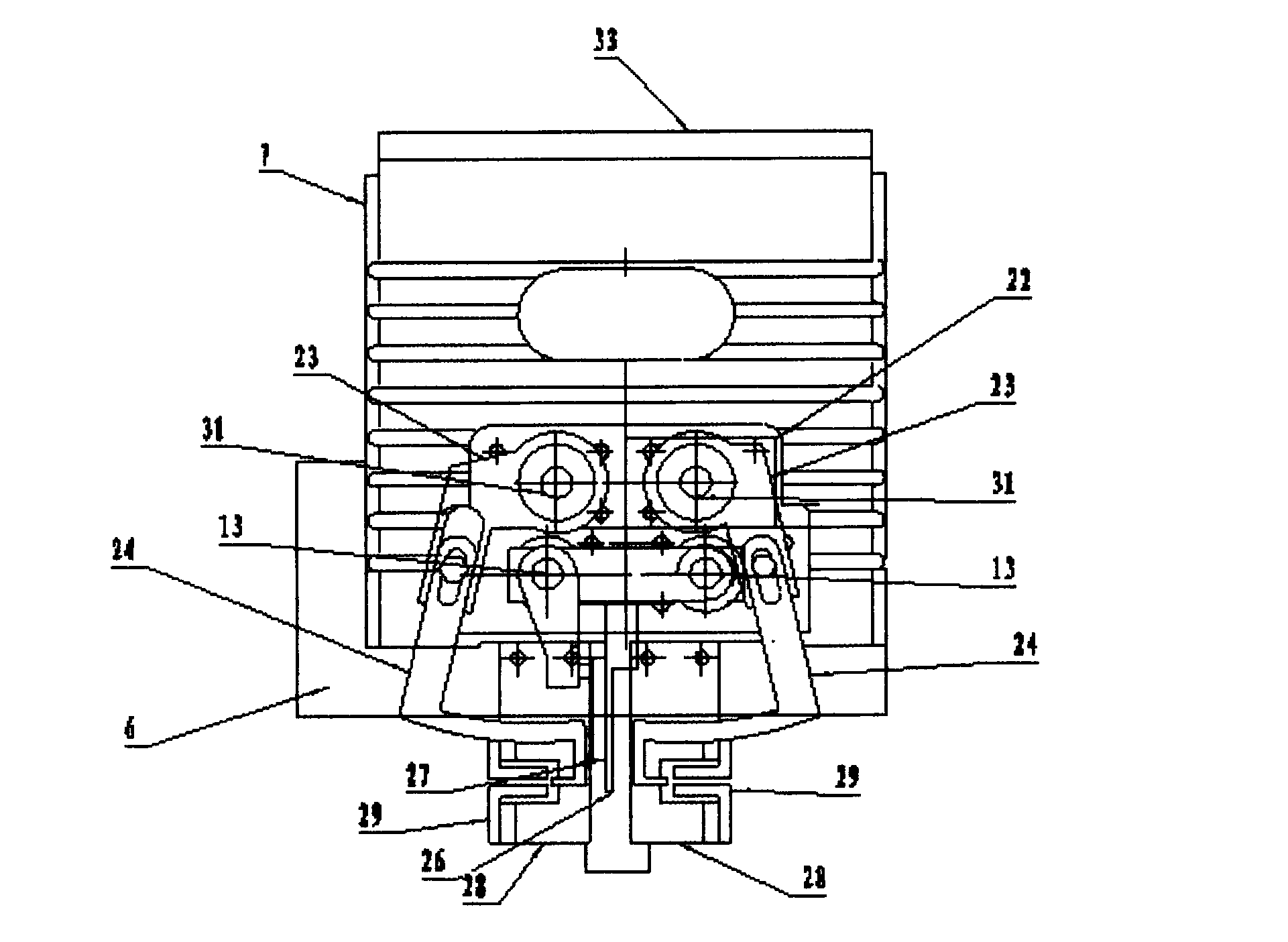

[0029] like Figure 1-6 As shown, a new type of wire mesh folding machine, its structure is mainly composed of: main shaft mechanism 1, swing arm mechanism 2, crochet needle mechanism 3, scissors mechanism 4, guide mechanism 5, base 6, box body 7, cover plate 33, etc. , the main shaft mechanism 1 is connected with the box body 7 through the bearing, and the main shaft mechanism 1 is connected with the swing arm mechanism 2 through the bearing, the swing arm mechanism 2 is connected with the box body 7 through the swing arm shaft 19, the scissors mechanism 4 and the crochet needle in the hook mechanism 3 The shaft 13 is fixed, the guide mechanism 5 is connected with the base 6, the base 6 is arranged at the lower end of the box body 7, and the top end of the box body 7 is provided with a cover plate 33.

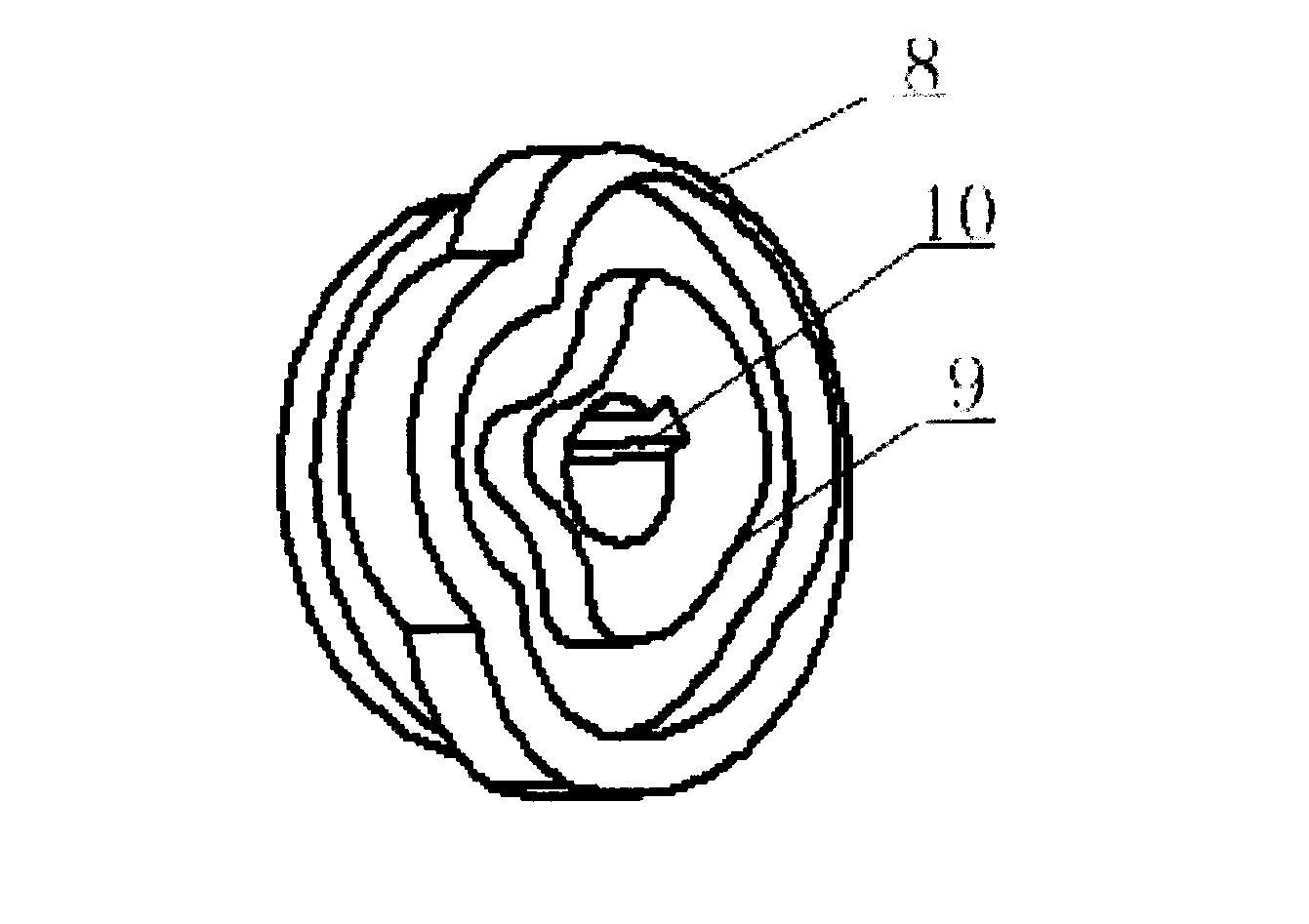

[0030] Described main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com