Water coating device and water coating method in fiber chopping process

A technology of water coating and chopping, which is applied in textiles and papermaking, textile material processing, liquid/gas/steam textile material processing, etc. It can solve the problem that the yarn is easily entangled on the water coating roller and avoid mutual wear , Reduce scrap rate, and facilitate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

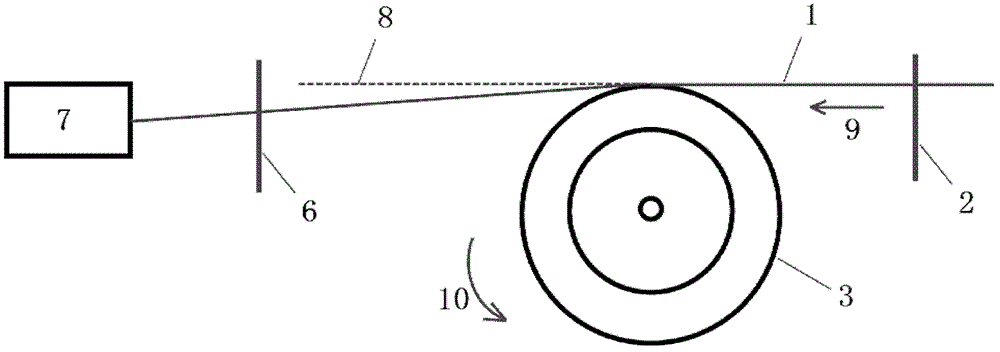

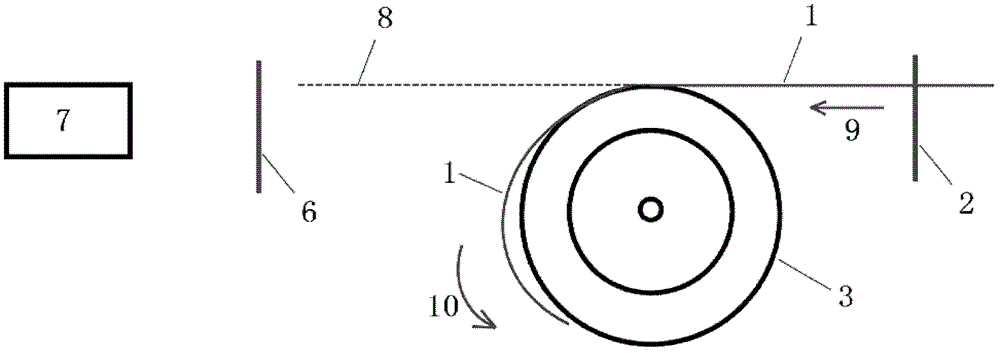

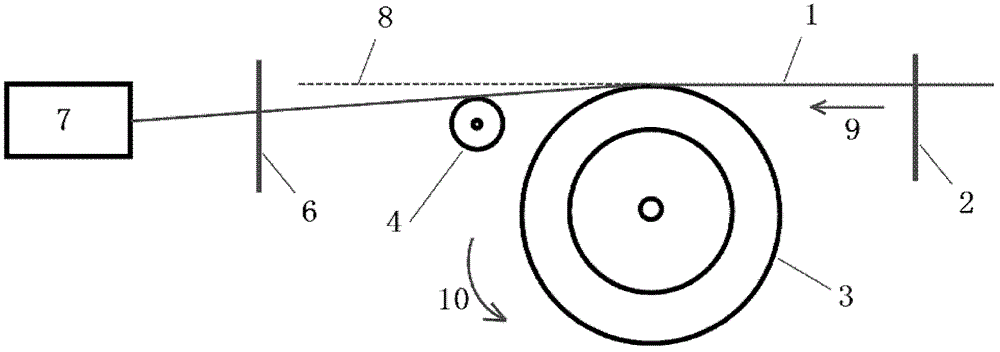

[0033] The invention provides a water coating device and a water coating method in the fiber chopping process, which solves the problem that the yarn is easily entangled on the water coating roller in the chopping process, improves the production efficiency, and reduces the reject rate. And the cost is low, the operation is simple and convenient, the original production process does not need to be changed, and the production efficiency is greatly improved.

[0034] The present invention will be further described below in conjunction with accompanying drawing.

[0035] A water applicator in the fiber chopping process, comprising a water applicator roller 3 and a driving device thereof. The driving device of the water applicator roller 3 may be a motor, and of course other power devices may also be used. The water application device can also include at least one tension rod 4, which is close to the water application roller 3 and arranged side by side with the water application ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com