Acoustic logging-while-drilling device and acoustic logging-while-drilling method

A sound wave and logging technology, applied in the field of applied geophysical logging, can solve the problems of difficult engineering implementation, large volume, increased power supply and energy consumption, etc., and achieve the effects of simple and convenient data processing, improved signal-to-noise ratio, and high engineering application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

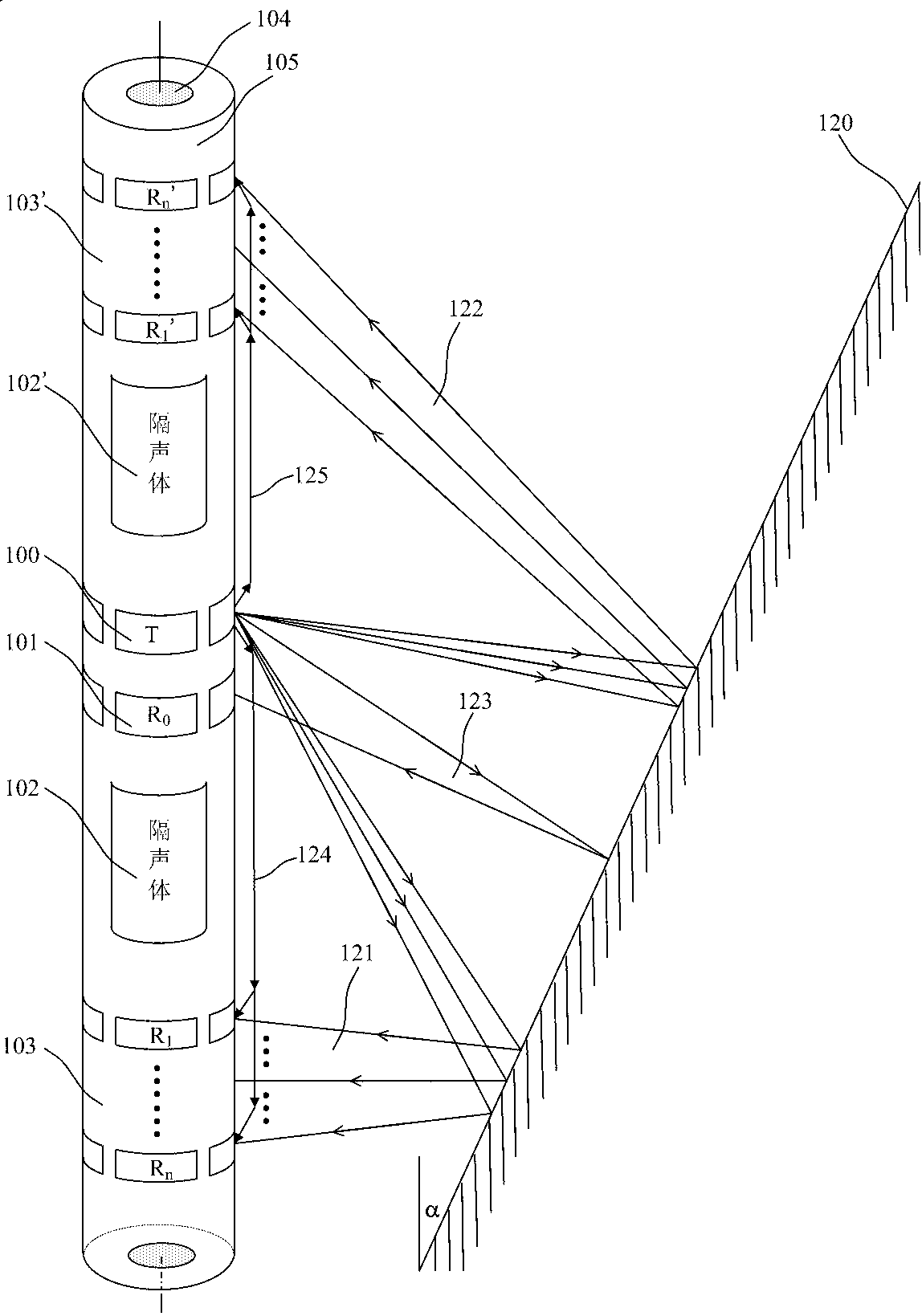

[0033] Below, the sonic logging while drilling device and method provided by the present invention will be further described in conjunction with the accompanying drawings.

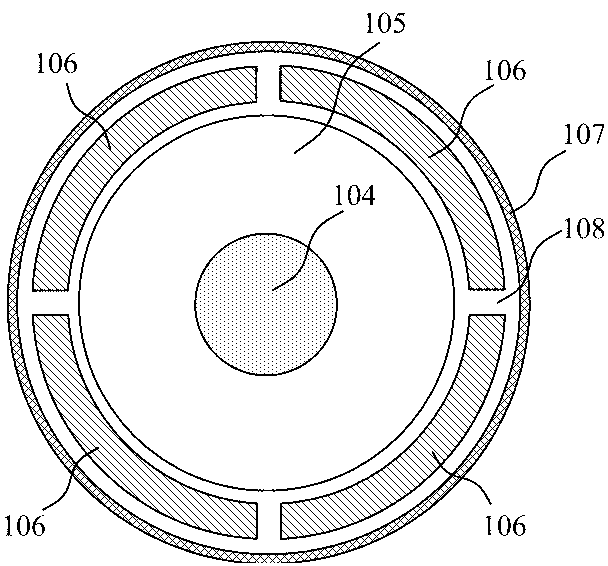

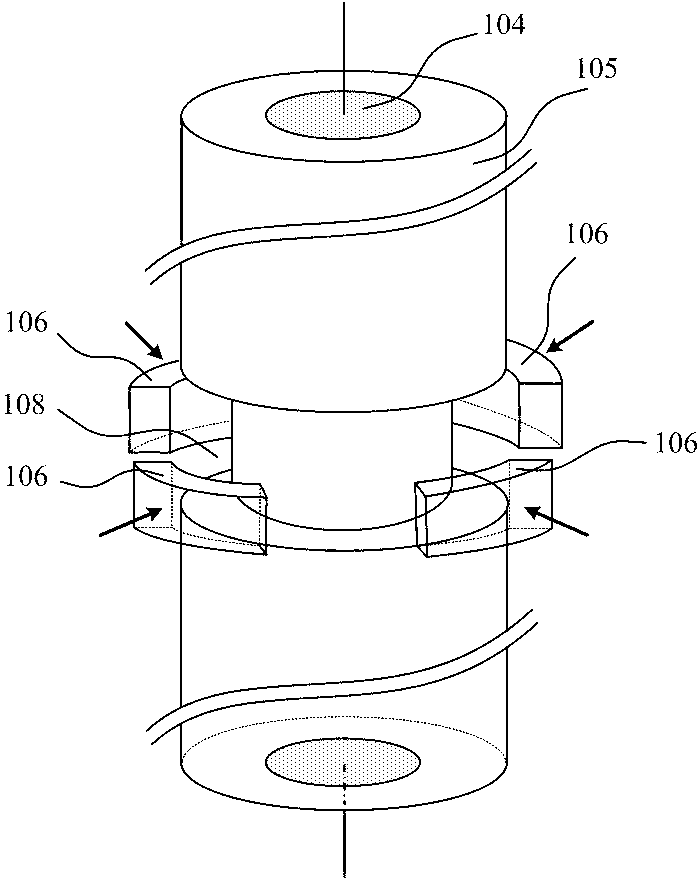

[0034] As shown in Fig. 1, the LWD device for determining the geological interface beside the well includes a drill collar 105, an acoustic wave transmitting transducer 100 (T), and a near-source acoustic wave receiving transducer 101 (R 0 ), the first sound insulator 102, the second sound insulator 102', the first far source distance acoustic wave receiving transducer array 103 (R 1 ~R n ), the second far-source acoustic wave receiving transducer array 103' (R 1 '~R n ') and control system (not shown in Fig. 1); the acoustic wave transmitting transducer 100 (T) has monopole radiation function, orthogonal dipole radiation function and quadrupole radiation function at the same time, and its radiated sound wave signal is along Borehole formation and outward propagation; near-source acoustic wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com