Ultrasonic magnetization filtration device

An ultrasonic and magnet technology, applied in the field of ultrasonic magnetization filter device, to reduce fuel consumption, improve purification effect, improve service life and power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

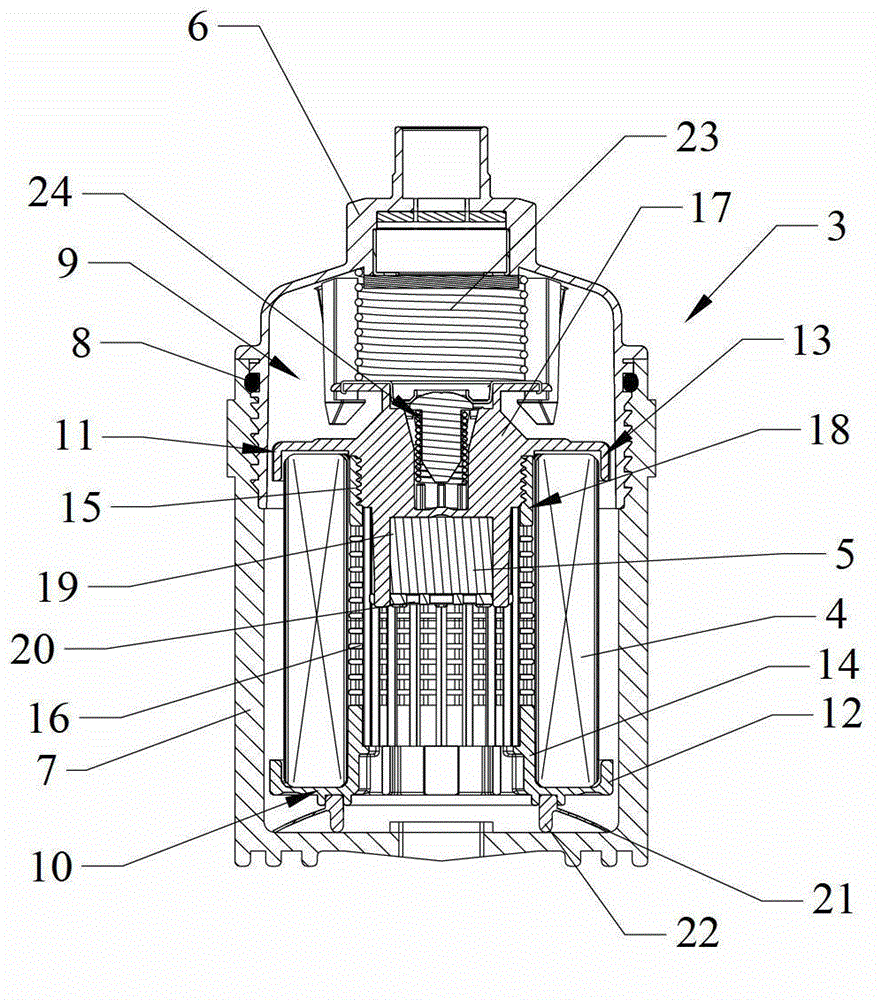

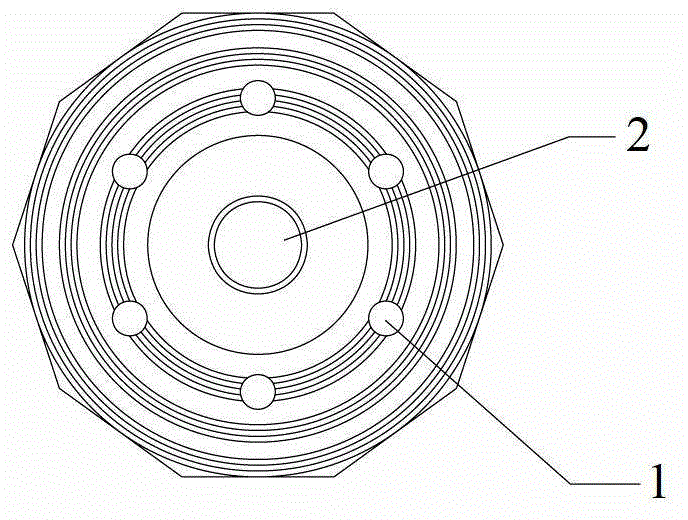

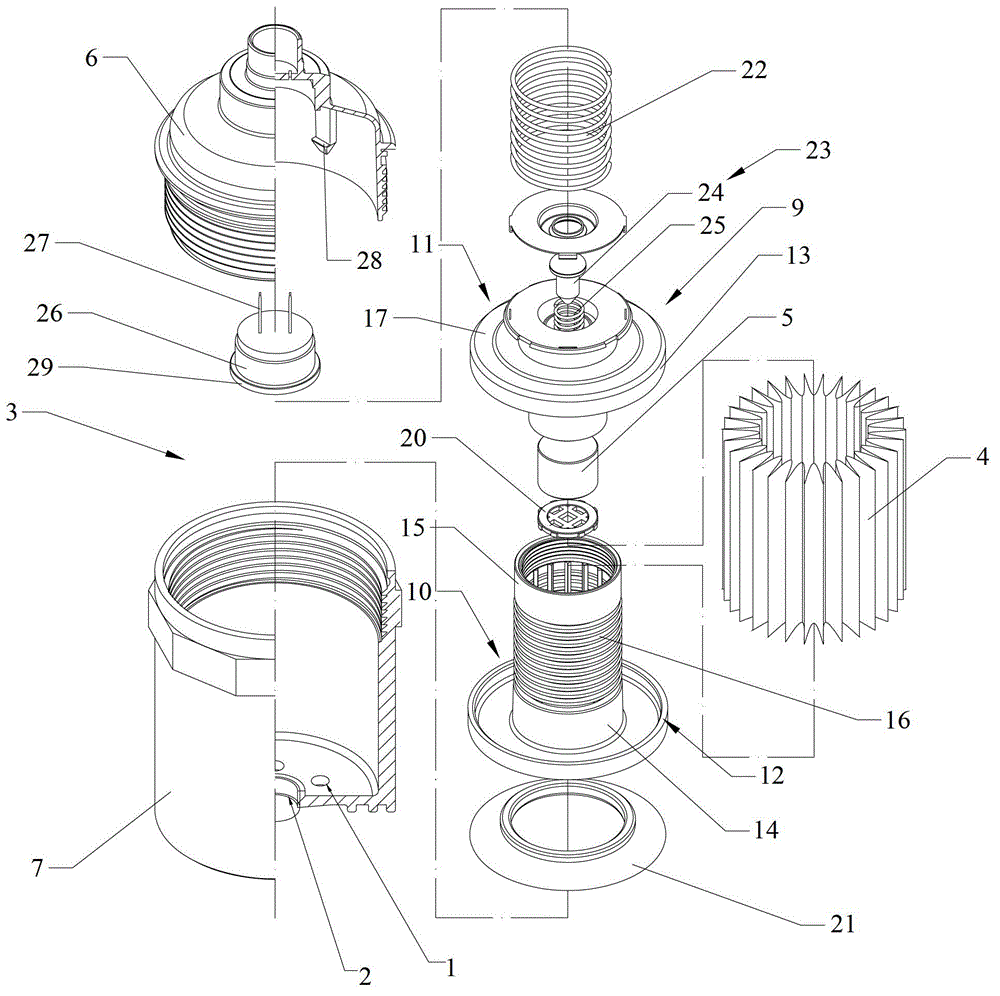

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A specific embodiment of the present invention see Figures 1 to 3 .

[0042] Such as figure 1 As shown, the ultrasonic magnetization filter device according to the embodiment of the present invention includes a housing 3 having an oil inlet hole 1 and an oil outlet hole 2, which is arranged in the housing 3 and located between the oil inlet hole 1 and the oil outlet hole. The filter element 4 between the oil holes 2, and the magnet 5 arranged in the housing 3. The housing 3 is provided with an ultrasonic transducer 26 for vibrating and separating engine oil and metal particles, and the ultrasonic transducer 26 is connected to an ultrasonic generator (not shown in the figure) through a cable. Wherein, the ultrasonic transducer 26 is arranged in an installation cavity with an opening facing the housing 3, the ultrasonic transducer 26 is a piez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com