Three-way frictional damping force adjustable vibration isolator for ship

A technology of friction damping and vibration isolator, applied in the direction of friction damper, shock absorber, shock absorber, etc., can solve the problems of metal vibration isolator easy to wear, rubber vibration isolator easy to aging, etc., and achieve strong corrosion resistance , improve stability and consistency, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

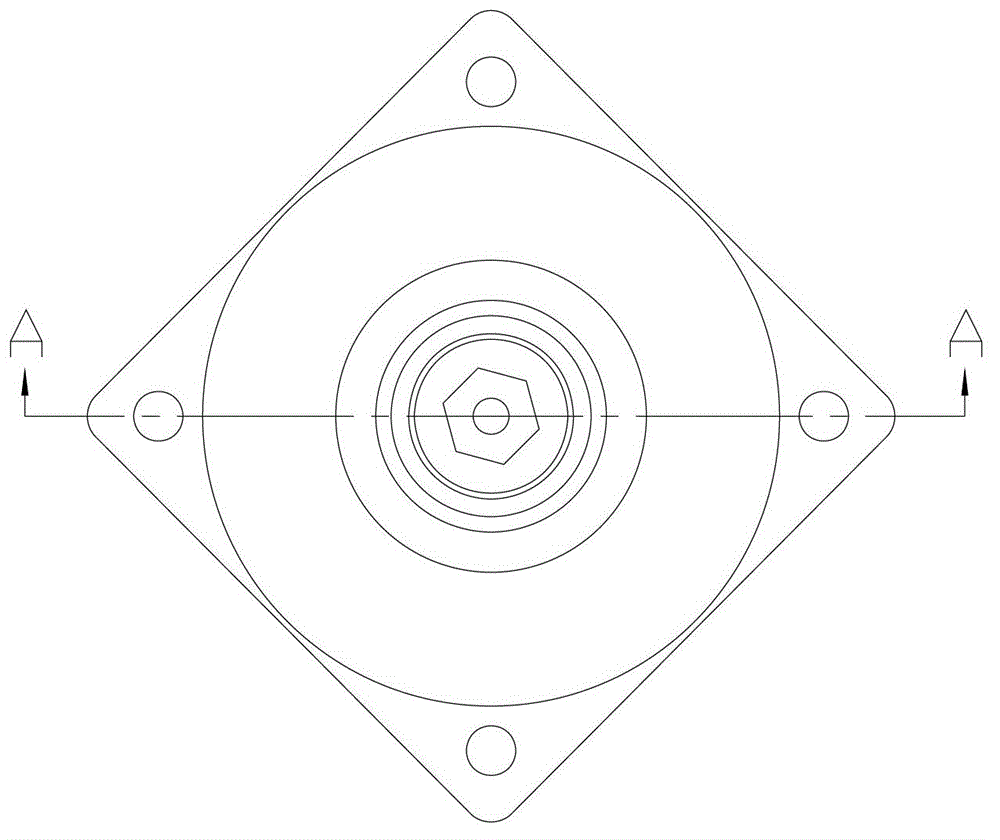

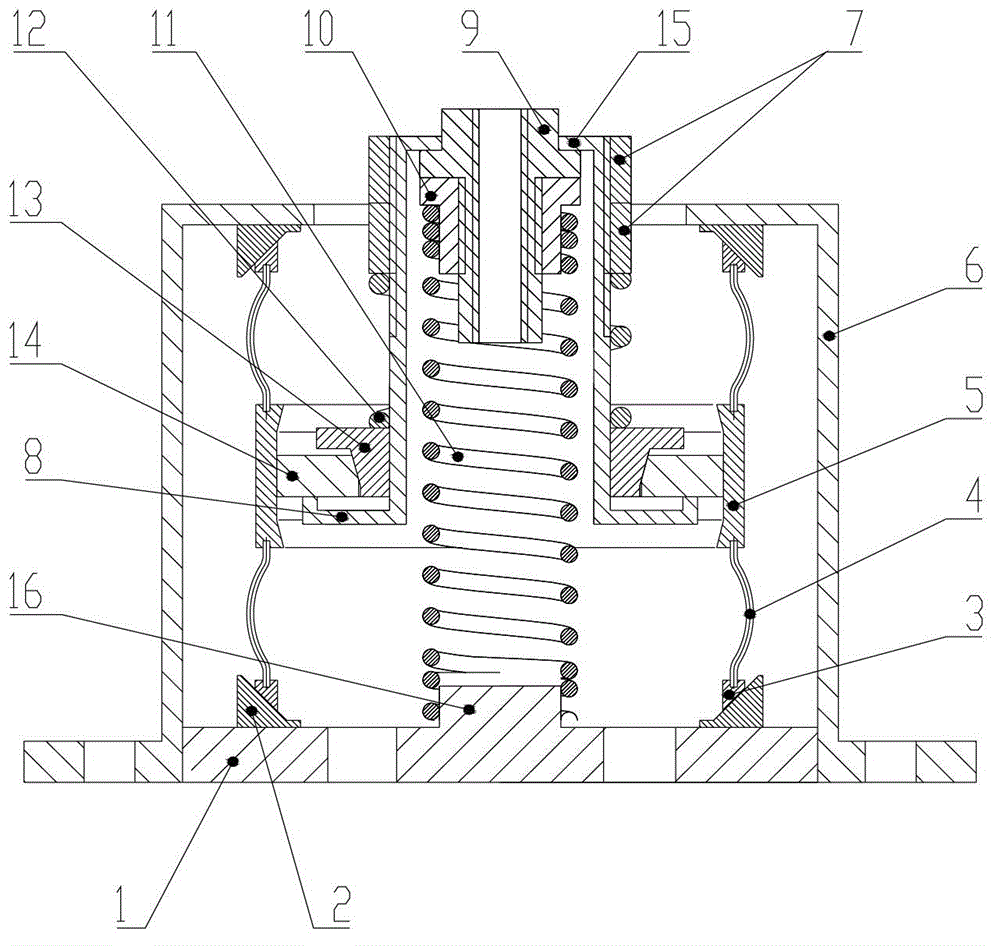

[0031] The present invention will be described in detail below in conjunction with accompanying drawing, as Figures 1 to 4 Shown: the three-way frictional damping force adjustable marine vibration isolator of the present invention includes a base 1, an upper cover 6 and a vibration isolation spring assembly, and the vibration isolation spring assembly is arranged in a cavity formed by the combination of the base 1 and the upper cover 6 In the chamber, the vibration isolation spring assembly includes a connecting bolt 9, a height adjustment nut 10 and a vibration isolation spring 11. The height adjustment nut 10 is threadedly connected to the lower end of the connection bolt 9. The relative position of the bolt 9 and the nut 10 is adjusted so that the vibration-isolated equipment is at the same installation height; the middle part of the base 1 is provided with a boss 16, and the lower part of the vibration-isolation spring 11 is sleeved on the boss 16 Above, the upper end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com