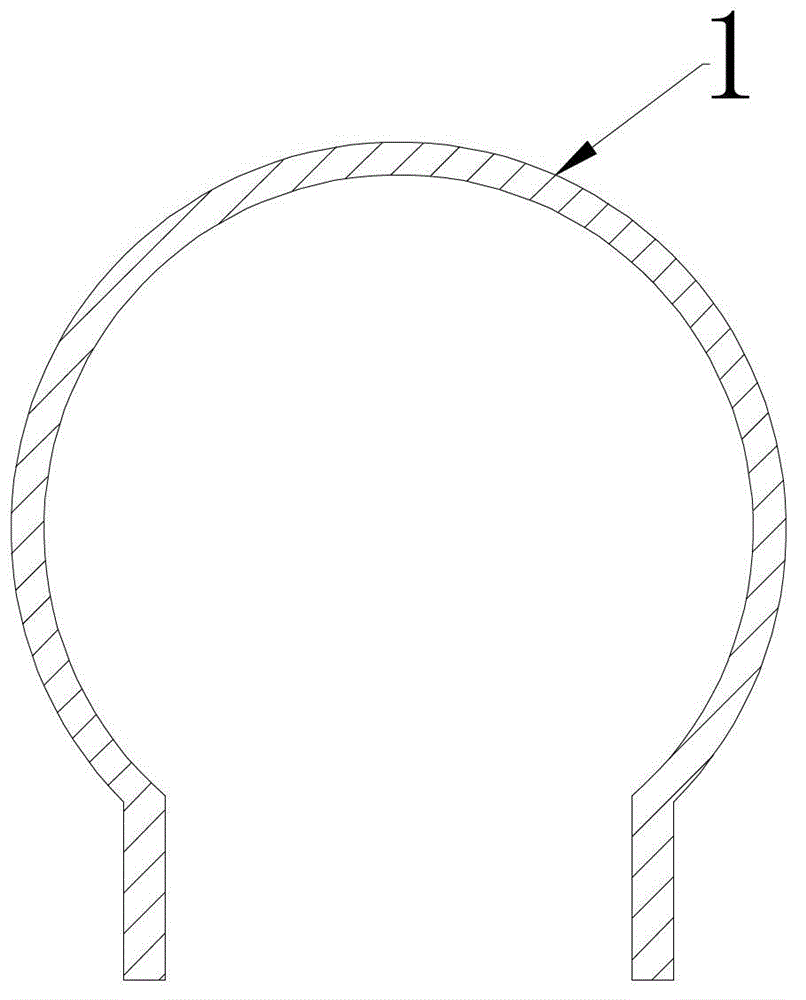

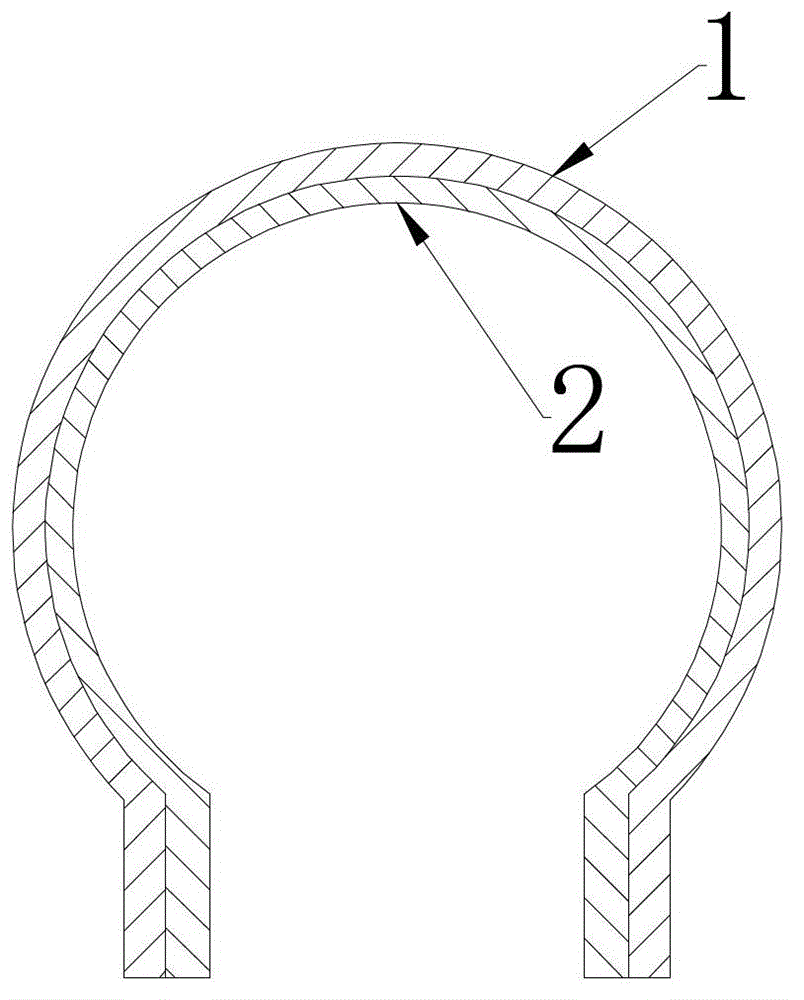

LED lampshade capable of improving lighting uniformity and fabrication method thereof

A technology of LED lampshade and manufacturing method, which is applied to the components of lighting devices, lampshades, lighting devices, etc., which can solve the problems of small luminous angle, high brightness, and less light output at the edge, so as to avoid excessive local brightness, uniform light output, and Improve the effect of the space glow angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

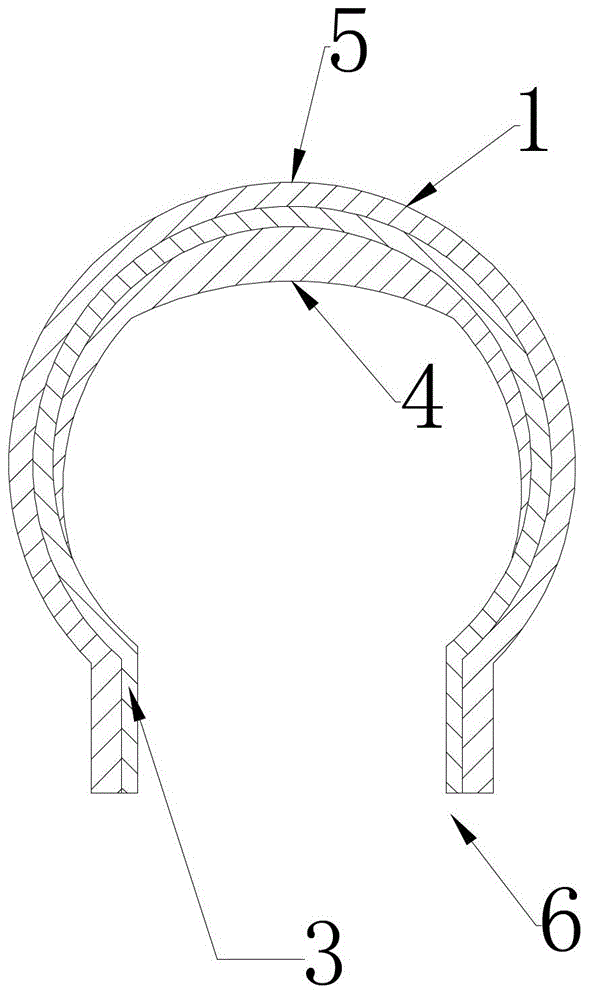

[0047] In the first step, Dow Corning 3140 alkoxy silica gel and silicon dioxide particles are mixed to form a mixture I with a silicon dioxide mass concentration of 15% and loaded into the first spraying equipment. The average particle size of the silicon dioxide particles used in this step is The diameter is 100 μm;

[0048] The second step is to mix Dow Corning 3140 alkoxy silica gel and glass particles to form a mixture II with a silica mass concentration of 40% and put it into the second spraying equipment. The average particle size of the glass particles used in this step is 200 μm ;

[0049] The third step is to open the lampshade body 1 downwards, spray the mixture I in the first spraying equipment on the top 5 of the lampshade body 1, and let the mixture I flow from the top 5 of the lampshade body 1 to the open end 6 of the lampshade body 1, In order to speed up the flow of the paint, it can be assisted with proper rotation to allow the lampshade body 1 to rotate aro...

Embodiment 3

[0054] The first step, mixing Dow Corning 1-2577 silica gel and silicon dioxide particles into a mixture I with a silicon dioxide mass concentration of 40% and loading it into the first spraying equipment, the average particle diameter of the silicon dioxide particles used in this step is 1000 μm;

[0055] In the second step, Dow Corning 1-2577 silica gel and glass particles are mixed into a mixture II with a silica mass concentration of 15% and loaded into the second spraying equipment. The average particle size of the glass particles used in this step is 2000 μm;

[0056] The third step is to open the lampshade body 1 downwards, spray the mixture I in the first spraying equipment on the top 5 of the lampshade body 1, and let the mixture I flow from the top 5 of the lampshade body 1 to the open end 6 of the lampshade body 1, In order to accelerate the flow of the mixture, appropriate rotation can be assisted to allow the lampshade body 1 to rotate around the central axis, and...

Embodiment 4

[0061] The first step, mixing Dow Corning 1-2577 silica gel and silicon dioxide particles into a mixture I with a silicon dioxide mass concentration of 40% and loading it into the first spraying equipment, the average particle diameter of the silicon dioxide particles used in this step is 1 μm;

[0062] In the second step, Dow Corning 1-2577 silica gel and glass particles are mixed into a mixture II with a silica mass concentration of 15% and loaded into the second spraying equipment. The average particle size of the glass particles used in this step is 500 μm;

[0063] The third step is to open the lampshade body 1 downwards, spray the mixture I in the first spraying equipment on the top 5 of the lampshade body 1, and let the mixture I flow from the top 5 to the opening end 6 of the lampshade body 1, in order to accelerate the mixture I The flow can be assisted by proper rotation to allow the lampshade body 1 to rotate around the central axis, relying on centrifugal force to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com