Air conditioner

An air conditioner and heat transfer tube technology, which is applied in the field of air conditioners, can solve the problems of insufficient technology for preventing heat conduction and improving thermal performance, and achieve the effect of improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

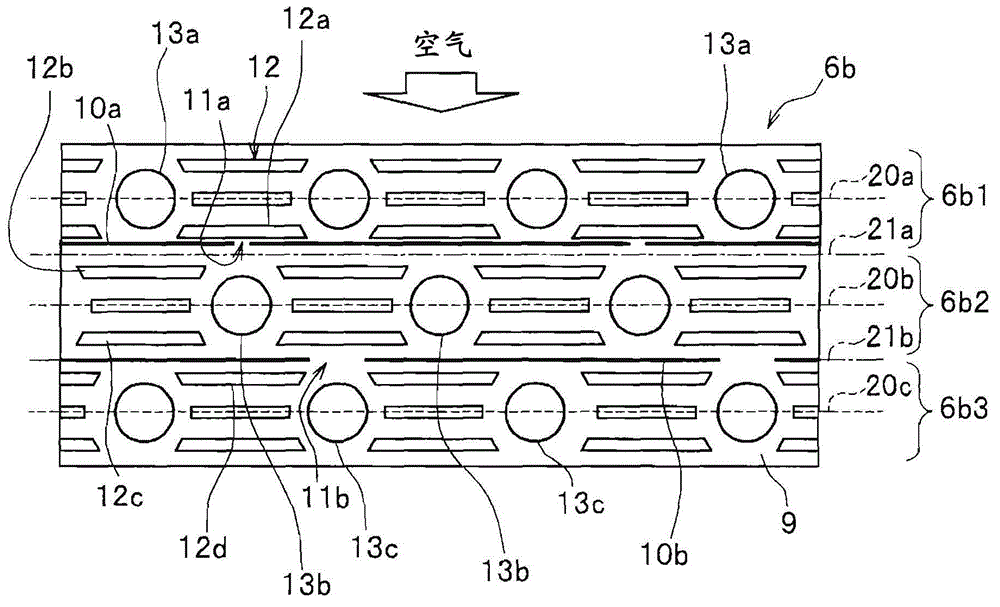

[0073] Next, refer to Figure 9 as well as Figure 10 , and the structure of the reheater 6bB of the second embodiment will be described. In addition, in the following description, the point of difference with the above-mentioned reheater 6b is mainly demonstrated, and the description of the same content is abbreviate|omitted for simplification. And, with image 3 The same components of the shown reheater 6b are assigned the same symbols, and detailed description thereof will be omitted. In addition, the configurations of the air conditioners other than the reheater 6b are the same as those described above.

[0074] Figure 9 as well as Figure 10 In the shown reheater 6bB, the positions of the connecting parts 11a, 11b are different from those in the above-mentioned reheater 6b. Specifically, the connector 11 a in the reheater 6 bB is provided at the center (substantially at the center) of the stage pitch of the heat transfer tubes 13 b in the second row. That is, it i...

no. 3 Embodiment approach

[0082] Next, refer to Figure 11 , and the structure of the reheater 6bC of the third embodiment will be described. It should be noted that in the following description, the main description is related to image 3 For the differences between the above-mentioned reheaters 6b, the description of the same content will be omitted for simplification. And, with image 3 The same components of the shown reheater 6b are assigned the same symbols, and detailed description thereof will be omitted. In addition, the configurations of the air conditioners other than the reheater 6bC are the same as those described above. In addition, in Figure 11 In , the description of the centerlines 20a, 20b, and 20c and the centerlines 21a and 21b between rows is omitted.

[0083] In the reheater 6bC, the thickness ratio of the heat transfer tube 13a image 3 The thickness of the heat transfer tube 13a in the shown reheater 6b is thick. That is, the inner diameter of the heat transfer tube 13a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com