Measurement method of large gear free of installation and regulation

A measuring method and technology for large gears, applied in measuring devices, instruments, etc., can solve the problems of low measurement efficiency of large gears, large measurement errors, and time-consuming adjustment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

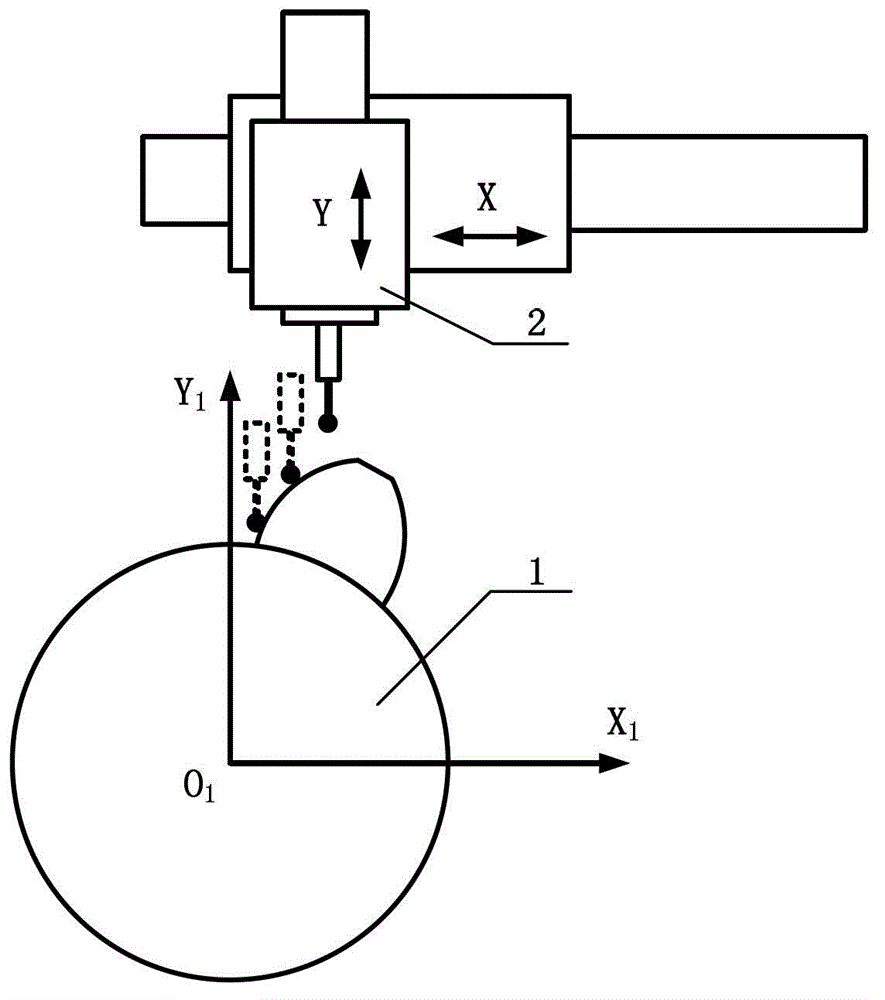

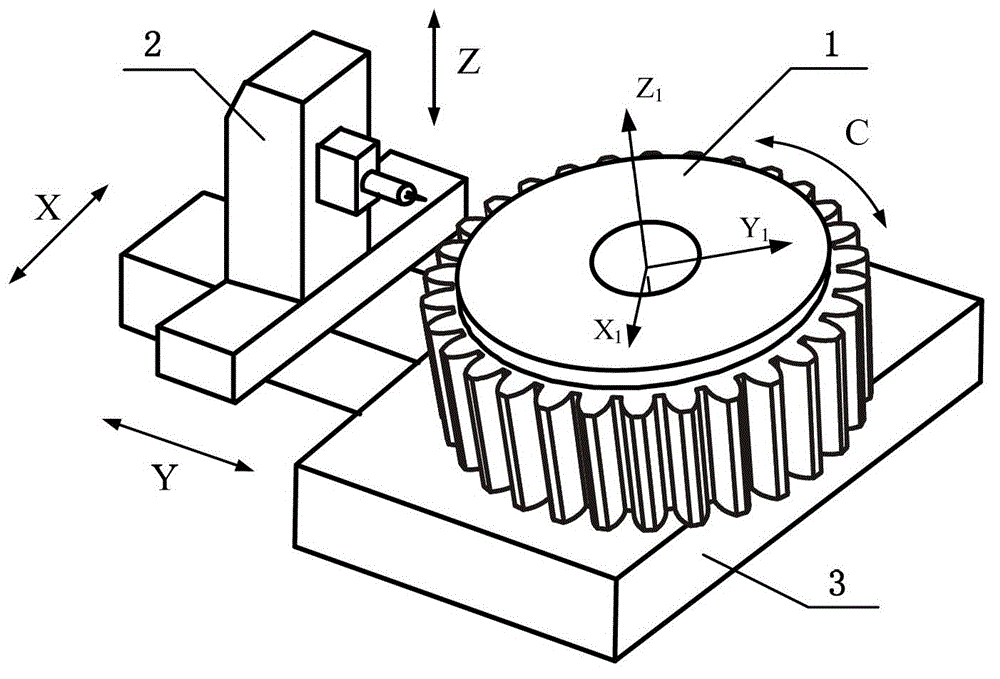

[0024] Such as image 3 As shown, the large gear cannot be positioned and installed with the center, and in this case, the task of measuring the tooth profile error needs to be completed. Using the method of the present invention, the measurement process is carried out according to the following steps:

[0025] 1) Install the measured gear workpiece 1 on the rotating platform 3 without adjusting the position and posture of the measured gear workpiece 1 relative to the measuring instrument 2. At this time, the measured gear 1 is inclined relative to the instrument.

[0026] 2) Measure several points on the reference plane and reference cylindrical surface at the upper end of the measured gear 1 through the measuring instrument 2, and use the plane measurement point to fit the plane through the least square method and obtain the plane normal vector, and use the cylindrical surface to measure the point through the least square Multiplicative fitting obtains the least squares circle ce...

Embodiment 2

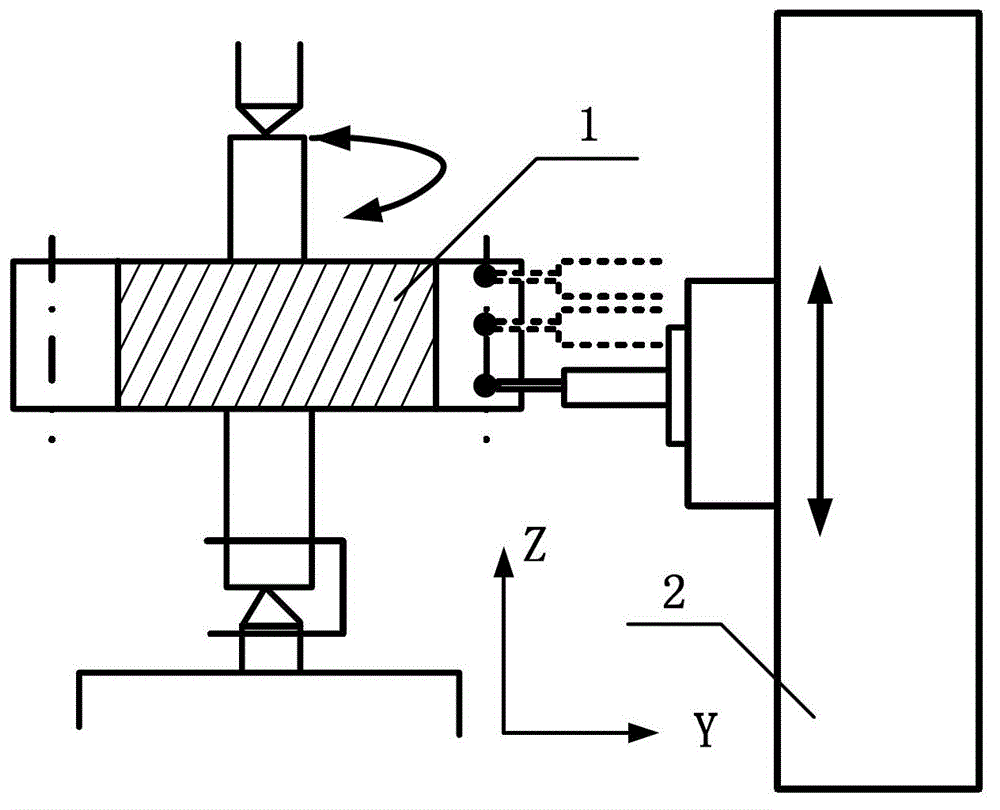

[0037] Such as Image 6 As shown, the big gear can be positioned and installed using the upper and lower centers, but the upper and lower centers have different axes. At this time, the measured gear 1 is inclined relative to the instrument. Applying the method of the present invention, the measurement process is carried out according to the following steps:

[0038] 1) Position the measured gear 1 through the upper and lower centers of the measuring instrument 2. Since the top position is fixed, the position and posture of the measured gear 1 relative to the measuring instrument 2 cannot be adjusted after positioning.

[0039] 2) Use measuring instrument 2 to measure several points on the upper and lower reference cylindrical surfaces of the measured gear 1 mandrel respectively, and perform least squares cylindrical fitting on all measuring points to get the gear axis Z 1 Vector. Use measuring instrument 2 to measure any point on the gear tooth surface, through which there is a ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com