Automatic sound emission monitoring method and automatic sound emission monitoring device

A technology of automatic monitoring and monitoring devices, which is applied in the fields of earthwork drilling, program control, instruments, etc., and can solve problems such as inability to realize automatic monitoring, sensor sticking, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

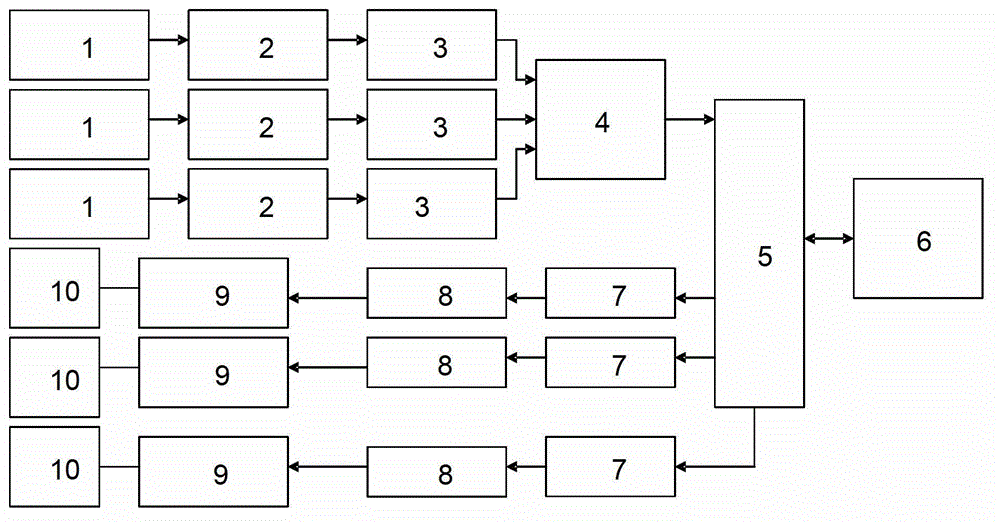

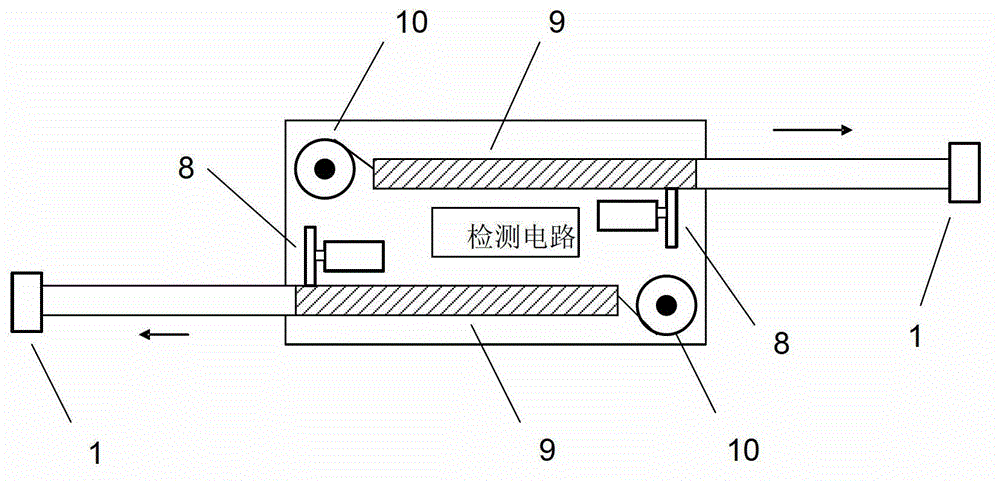

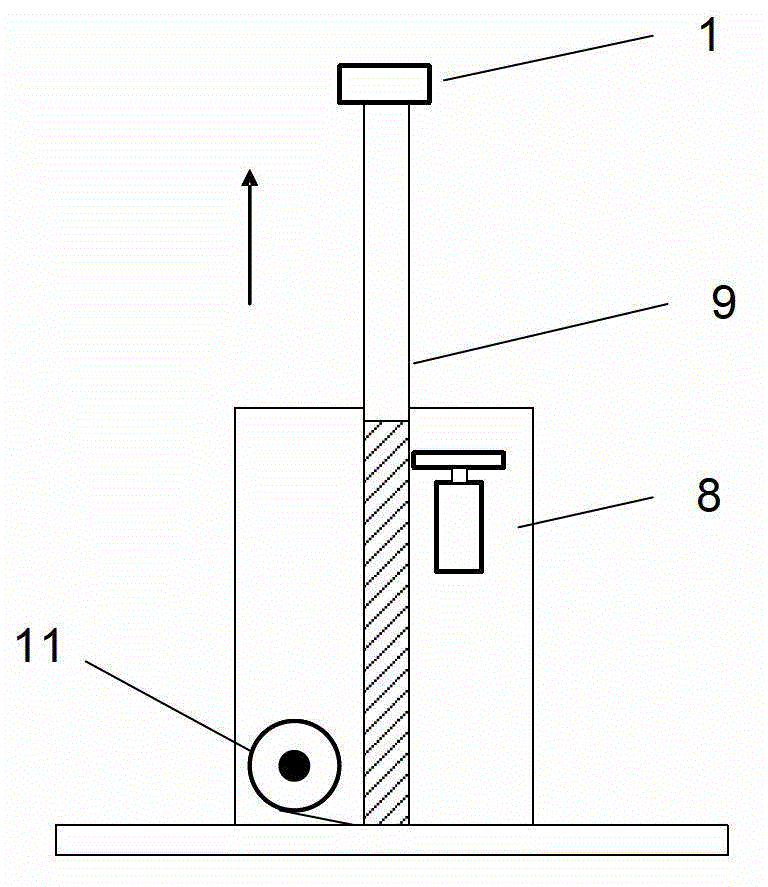

[0014] Such as figure 1 As shown, the acoustic emission automatic monitoring method and device of the present invention include a single-chip microcomputer 5, and the input terminals of the single-chip microcomputer 5 are respectively connected with an A / D converter 4 and a communication circuit 6, and the communication circuit includes a wireless communication and a wired communication circuit , the wireless communication is used to transmit the acoustic emission monitoring signal to the ground receiving base station, the wired communication is used for the communication between the monitoring device and the mobile carrier control circuit, and the input ends of the A / D converter 4 are respectively connected with a plurality of acoustic emission detection circuits, The output end of the single-chip microcomputer 5 is connected with a plurality of telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com