Special syrup for baking in preparation of moon cakes and bread and preparation method thereof

A bread and moon cake technology, applied in the field of food raw materials and their preparation, can solve the problems of rising white sugar prices, reducing production costs, complicated processes, etc., and achieve the effects of saving production costs, low prices, and simple baking processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

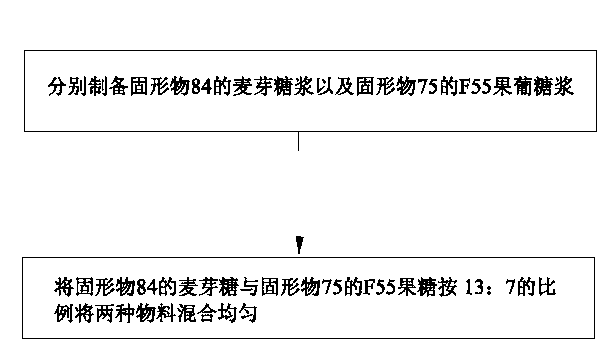

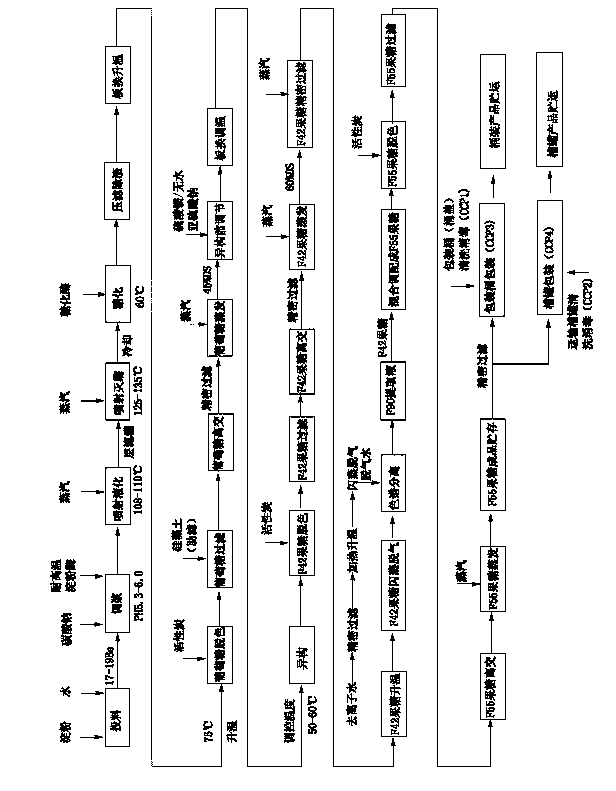

[0046] 1) Prepare maltose syrup with 84% solids

[0047] Feeding: Mix cornstarch with water to prepare a starch slurry with a concentration of 18 degrees Baume;

[0048] Sizing: Add sodium carbonate and high temperature resistant α-amylase to the starch slurry, stir evenly, and adjust the pH value of the slurry to 5.5; the starch slurry for mixing is filtered through a 30-mesh filter from the starch slurry after feeding obtained after.

[0049]Jet liquefaction: Jet liquefaction is carried out by steam under the condition of 110°C; the slurry before jet liquefaction is obtained by filtering the mixed slurry through a 30-mesh filter. The intelligent liquefaction injector is used to heat the starch slurry with steam, and it is degraded and liquefied under the action of liquefying enzymes to prepare for the subsequent saccharification.

[0050] Enzyme inactivation by spraying: the liquefied liquid is sprayed at 127°C by steam to inactivate the high-temperature-resistant amylase ...

Embodiment 2

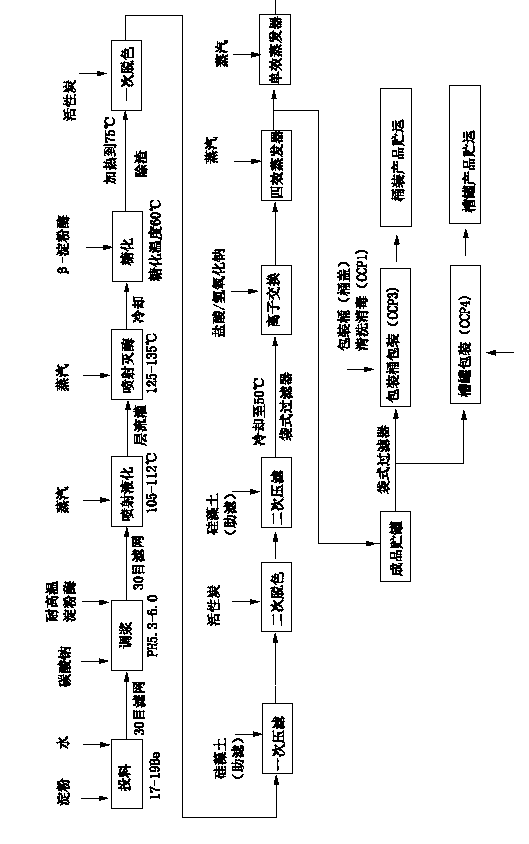

[0082] 1) Prepare maltose syrup with 84% solids

[0083] Feeding: Mix cornstarch with water to prepare starch slurry with a concentration of 19 degrees Baume;

[0084] Blending: add sodium carbonate and high temperature-resistant α-amylase to the starch slurry, stir evenly, and adjust the pH value of the slurry to 5.8; the starch slurry after feeding is filtered through a 30-mesh filter obtained after.

[0085] Jet liquefaction: Jet liquefaction is carried out by steam at 106°C; the slurry before jet liquefaction is obtained by filtering the conditioned slurry through a 30-mesh filter. The intelligent liquefaction injector is used to heat the starch slurry with steam, and it is degraded and liquefied under the action of liquefying enzymes to prepare for the subsequent saccharification.

[0086] Enzyme inactivation by spraying: the liquefied liquid is sprayed at 130°C by steam to inactivate the high-temperature-resistant amylase to obtain a liquefied slurry;

[0087] Sacchar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com