Tapping machine

A technology of tapping machine and rack, applied in the field of tapping machine, can solve the problems of difficulty in ensuring product quality, waste of time and manpower, low degree of automation, etc., and achieve the effect of improving the degree of automation, improving work efficiency, and moving smoothly and accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

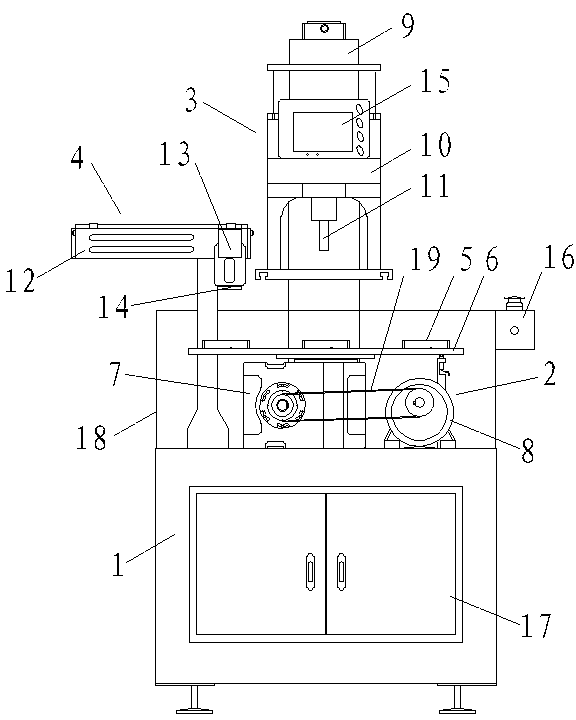

[0023] Such as figure 1 As shown, a kind of tapping machine of the present invention comprises frame 1, conveying device 2, tapping device 3, retrieving device 4 and tapping jig 5, conveying device 2, tapping device 3, retrieving device 4 are respectively Set on the frame 1, the conveying device 2 includes a positioning turntable 6, a rotary divider 7 and a motor 8 that control the rotation angle of the positioning turntable, and the positioning turntable 6 is arranged on the output shaft of the rotary divider 7, and the motor 8 and the rotary divider 7 It is a transmission connection; the tapping device 3 is arranged at the tapping station of the conveying device 2 , the reclaiming device 4 is arranged at the reclaiming station of the conveying device 2 , and the tapping jig 5 is arranged on the positioning turntable 6 .

[0024] There are at least three tapping jigs 5, and the rotary divider 7 is provided with at least three graduations. The number of tapping jigs 5 is dete...

Embodiment 2

[0030] The rest are the same as in Embodiment 1, the difference is that a photoelectric protection device is also provided for safety protection. By arranging the photoelectric protection device, when the tapping machine is in the working state, if something or the hand of the operator enters, After receiving the signal, the photoelectric protection device controls the tapping machine to stop working, which ensures the safety of production and the personal safety of operators.

Embodiment 3

[0032] The rest are the same as in Embodiment 1, the difference is that an automatic feeding device is also provided to automatically discharge the product through machine control, further improve the automation of the tapping machine, improve work efficiency, save personnel costs, and ensure that personnel personal safety.

[0033]The beneficial effects of adopting this technical solution are: since at least three tapping jigs are arranged on the positioning turntable, and a retrieving device is also provided at the same time, the material is automatically reclaimed and manually discharged while tapping, and the degree of automation is improved; There are at least three jigs, and the corresponding stations include a discharging station, a tapping station and a retrieving station. When the tapping device is tapping at the tapping station, the reclaiming device is automatically taken out to complete the tapping. Products, and workers manually put materials on the vacant tapping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com