Locating tool assembly for welding of automobile instrument panel support

A technology for welding positioning tooling and automobile instrument panel, which is applied in the field of tooling and fixtures, can solve the problem that welding positioning tooling cannot meet high precision, etc., and achieves the effect of satisfying precision assembly and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

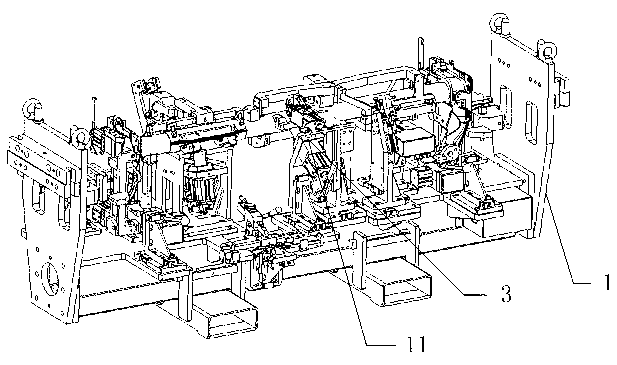

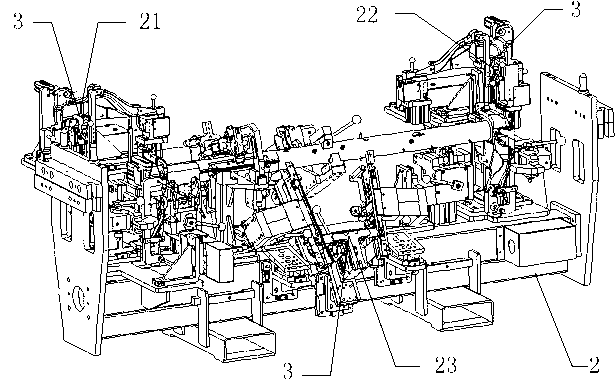

[0012] A kind of automobile instrument panel support welding positioning frock of the present embodiment is used for positioning the automobile instrument panel support with the L plates at both ends and the middle block in the middle position and the middle positioning panel, such as Figure 1~Figure 2 As shown, the first tooling 1 and the second tooling 2 are included, the first tooling 1 is provided with a first positioning block 11 for positioning the middle block; the left and right ends of the second tooling 2 are provided with L plates for positioning the two ends The second positioning block 21 and the third positioning block 22, and the fourth positioning block 23 for positioning the middle positioning panel is arranged in the middle of the second tooling 2 . Position sensors 3 are respectively provided on the first positioning block 11 , the second positioning block 21 , the third positioning block 22 and the fourth positioning block 23 .

[0013] The automobile inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com