Protective device and method of electric main shaft and thinning machine

A technology for protection devices and electric spindles, applied in grinding/polishing safety devices, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as insufficient protection against liquid leakage, damage to electric spindles, locked electric spindles, etc., to achieve The effect of stabilizing the working state and improving the stability of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

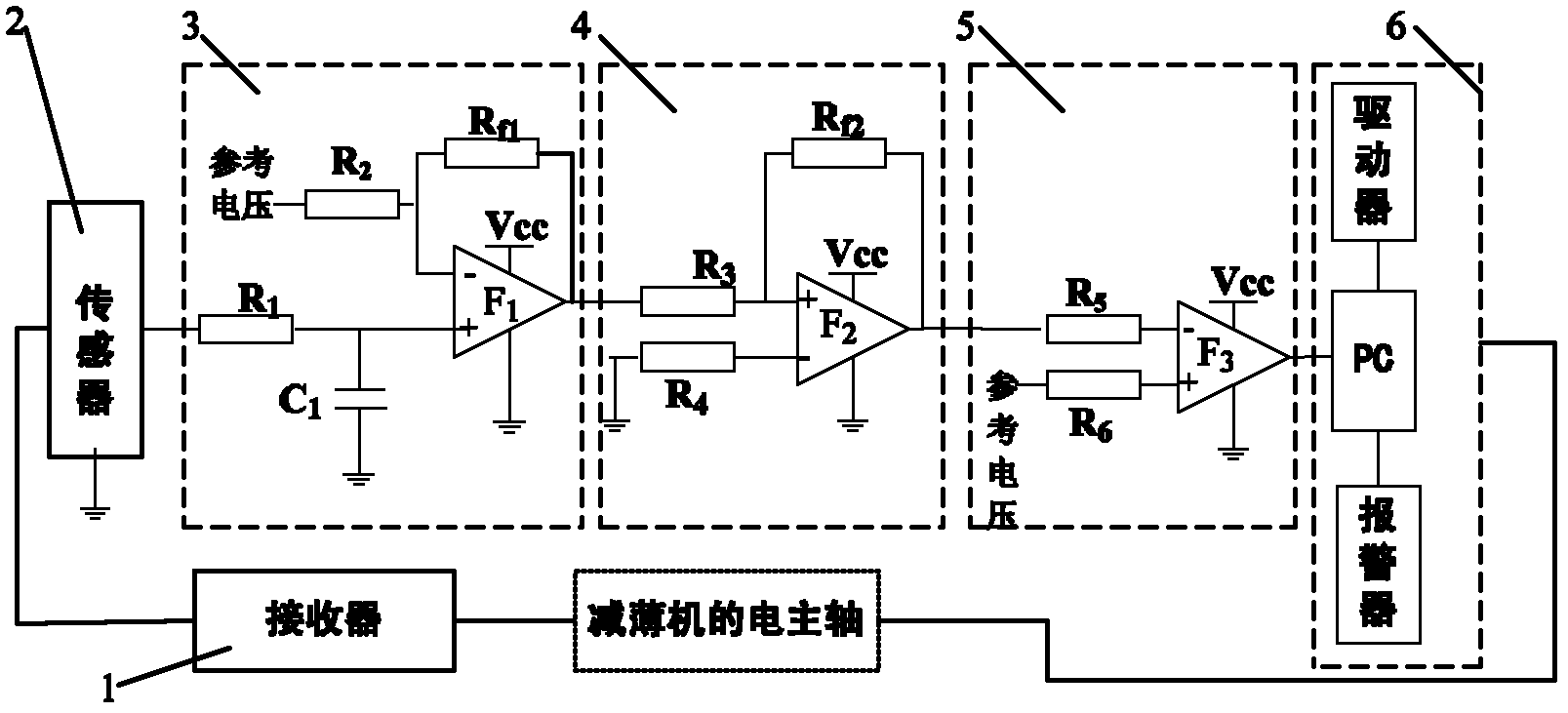

[0049] Such as figure 1 As shown, an embodiment of the present invention is a protective device for an electric spindle, including: a receiving module 1 (such as a receiver), used to receive the coolant overflowing from the grinding coolant inlet center hole of the electric spindle, and further Ground, the receiving module 1 can also export the received cooling liquid; the sensing module 2 (such as a sensor) is used to connect with the receiving module 1 and detect the voltage between two predetermined detection points in the receiving module , and output a voltage signal; the filter circuit module 3 is used to filter the voltage signal output by the sensing module 2, and output the filtered voltage signal; the amplifying circuit module 4 is used to filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com