Pipe cutter with automatic meter counting function

A meter pipe cutting machine, automatic technology, applied in metal processing, etc., can solve the problems of manual cutting, irregular incision, high labor cost, etc., and achieve stable and reliable material cutting, accurate material cutting, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described below in conjunction with specific embodiments.

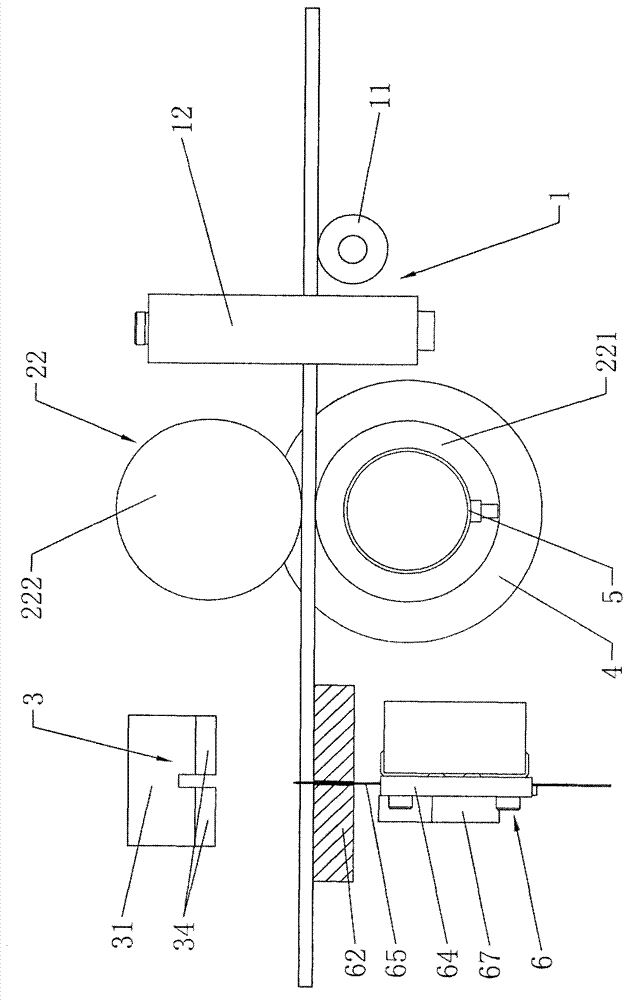

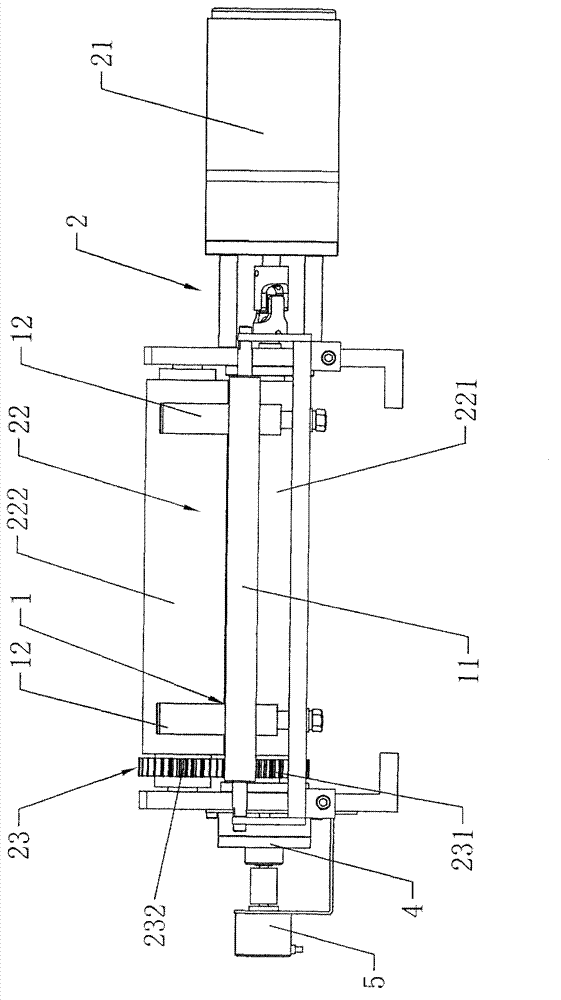

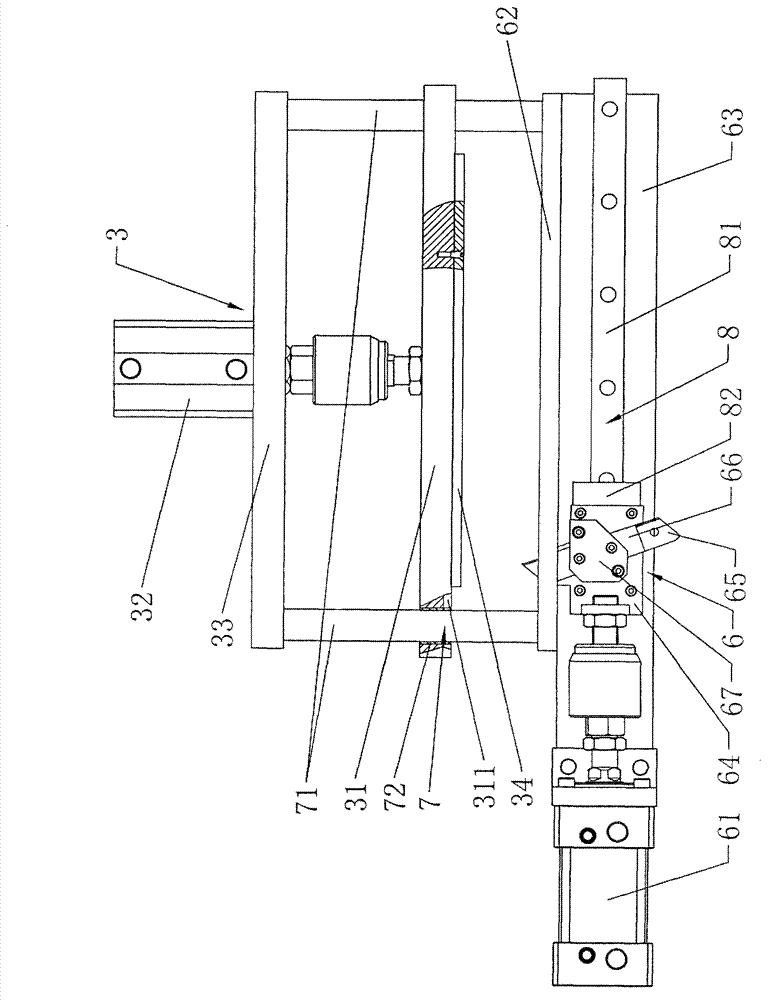

[0037] Such as Figure 1 to Figure 5 As shown, an automatic meter meter pipe cutting machine includes a frame, and the frame is equipped with a guiding and positioning mechanism 1, a feeding traction mechanism 2 and a pressing mechanism 3 arranged in sequence along the feeding direction, and the feeding traction mechanism 2 includes There is a torque motor 21 with adjustable output torque and a traction roller group 22 driven by the torque motor 21. The traction roller group 22 includes a driving traction roller 221 and a driven traction roller arranged in parallel and spaced apart and respectively rotatably mounted on the frame. Roller 222, torque motor 21 is driven and connected with active traction roller 221, active traction roller 221 is equipped with electromagnetic brake 4 and synchronously rotating meter encoder 5, and the bottom of pressing mechanism 3 is equipped with a c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap