Material rolling turning over vehicle

A technology for turning over vehicles and material rolls, which is applied in the field of material roll overturning vehicles, can solve the problems of increasing the use time of lifting equipment, wasting time, etc., and achieves the effect of avoiding the replacement of spreaders, reducing the quantity, and improving the use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of this patent, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

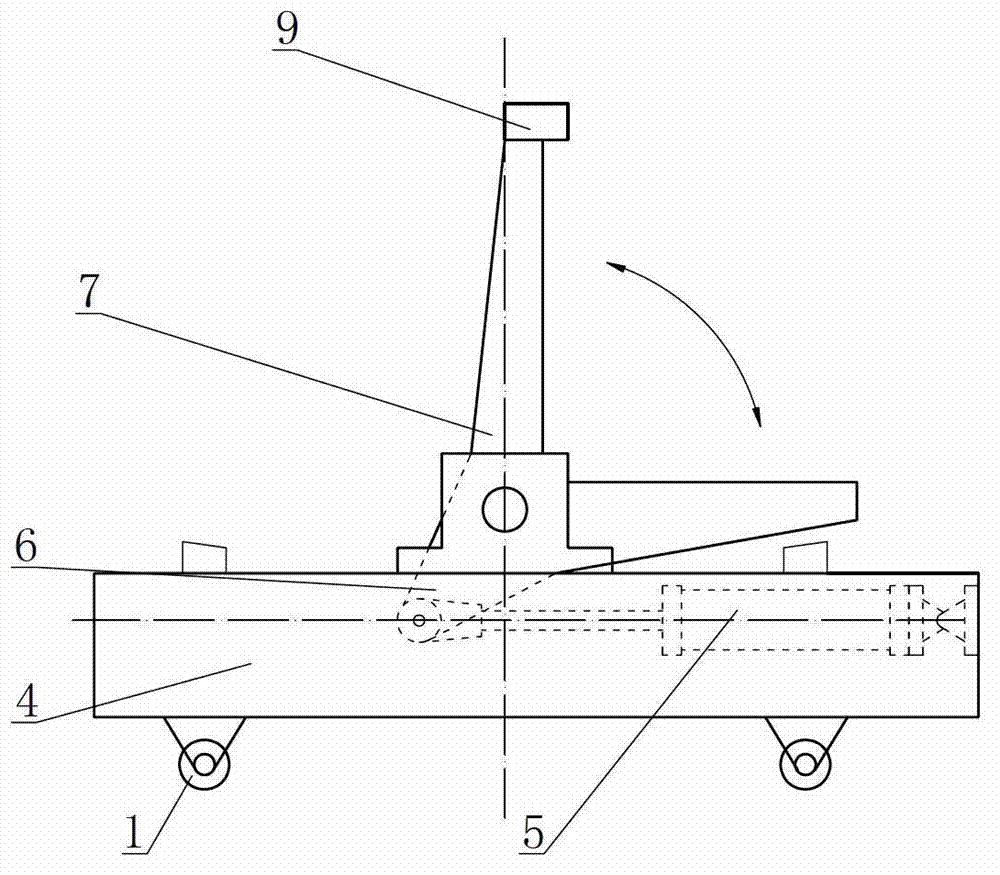

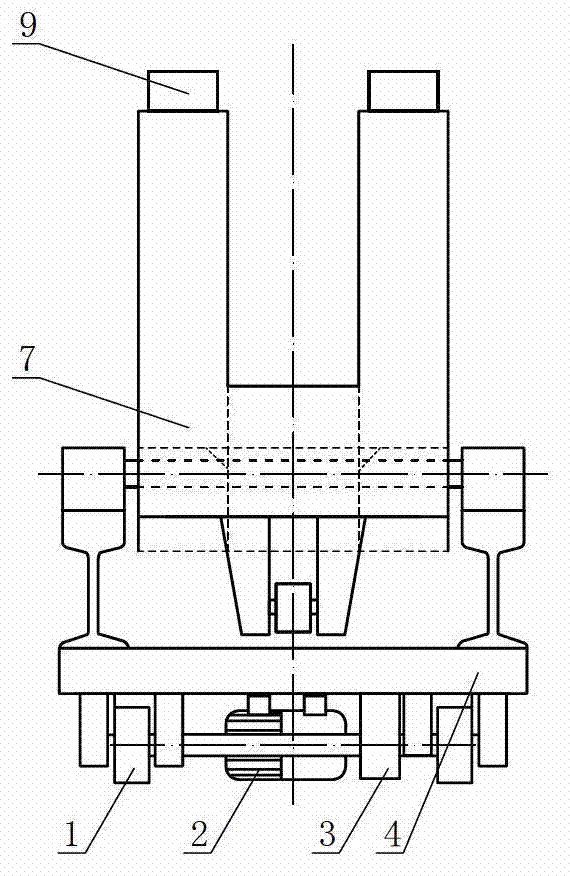

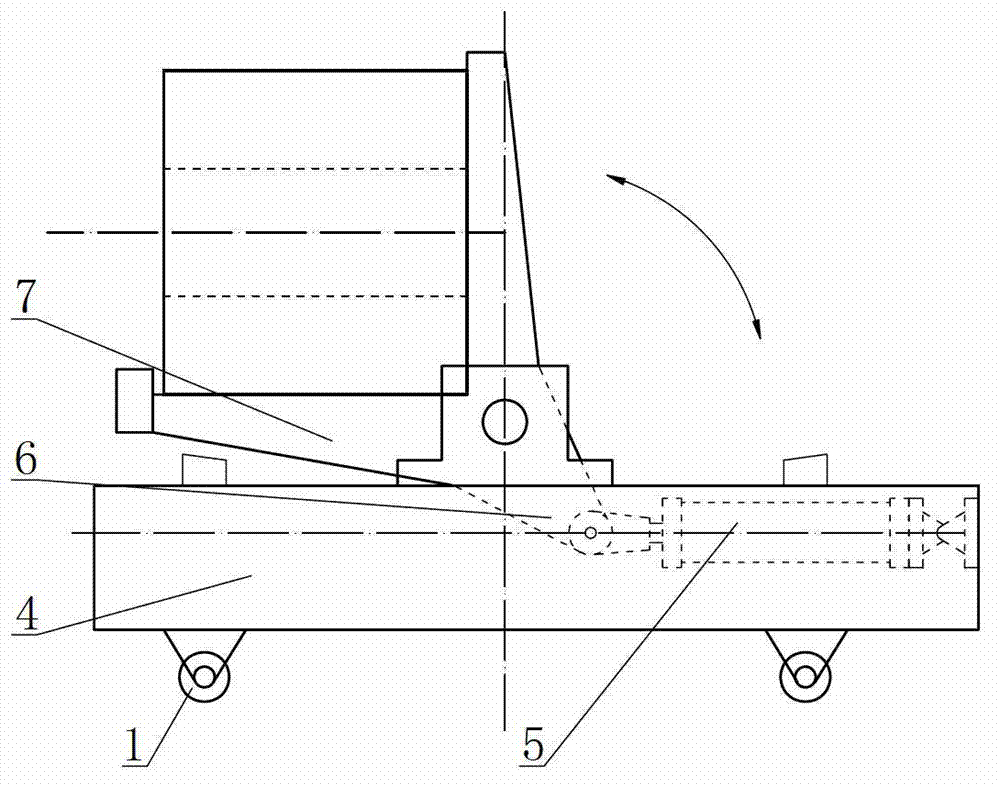

[0016] see Figure 1 to Figure 2 , a roll overturning vehicle, comprising an overturning device and a vehicle body on which the overturning device is installed, and a vehicle moving device driven by an electric motor is also provided on the vehicle body.

[0017] Specifically, the overturning device includes an overturning frame hinged on the car body. The bottom of the overturning frame is provided with an ear part hinged with the oil cylinder joint, and the tail of the oil cylinder is also hinged on the car body. The hinge shaft at the bottom rotates to realize the flipping of the roll. There is also an end stopper at the end of the overturning frame, because in the process of overturning, assuming that the overturning frame is overturned at a unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com