A kind of plastic buffer structure and its application

A buffer structure and plastic technology, applied in the direction of preventing mechanical damage, containers, transportation and packaging, etc., can solve the problems of reduced buffer performance, high production cost of composite materials, inability to meet buffer performance, etc., to meet buffer requirements, reduce The effect of environmental pollution and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

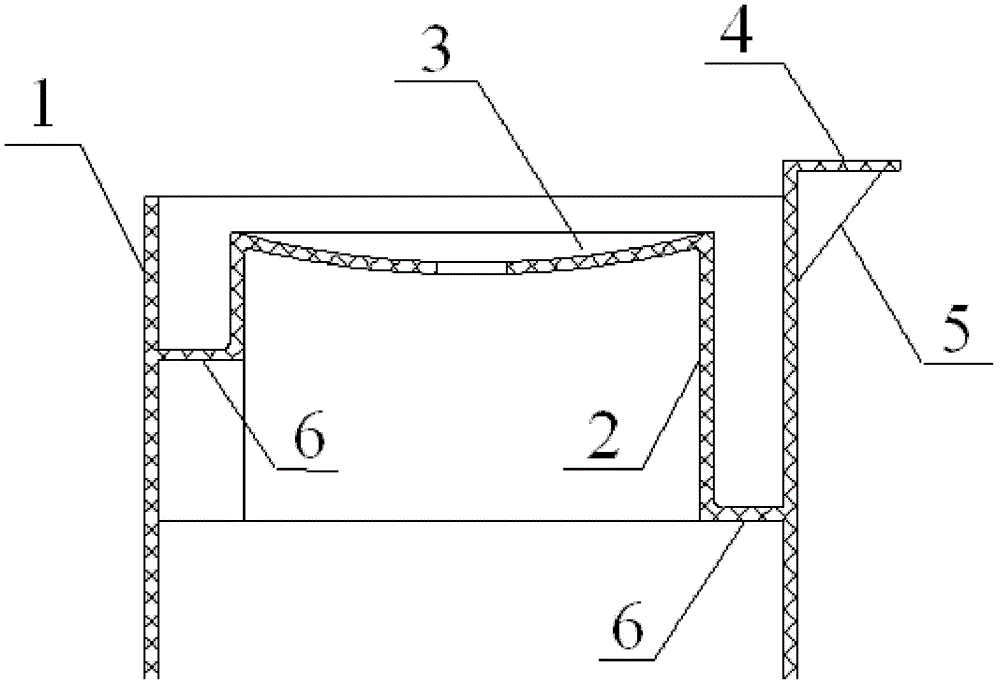

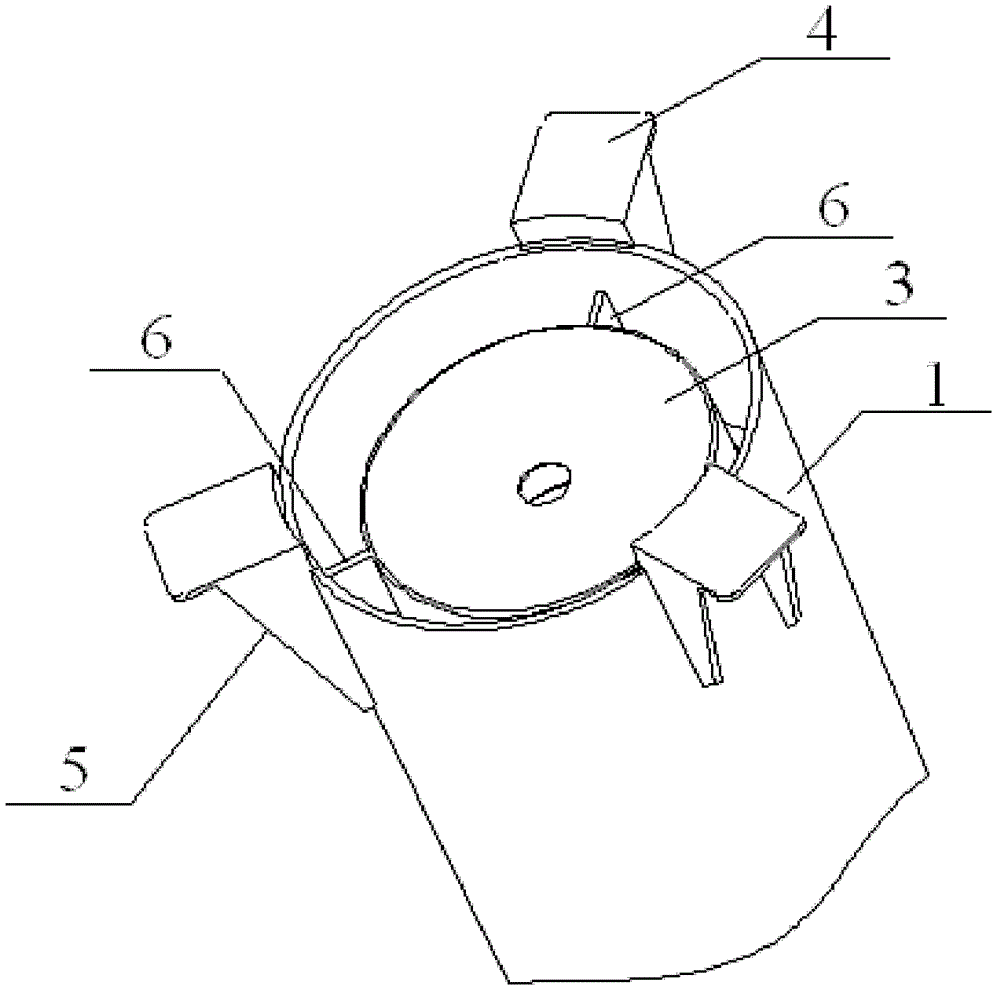

[0024] A new type of plastic buffer structure, the buffer structure such as Figure 1~2 shown. Made of continuous fiber reinforced polypropylene engineering plastics. It can be seen from the schematic diagram that the outside is a hollow cylinder, and there is a coaxial hollow cylinder inside. There is a groove 3 on the top of the buffer structure. There is an opening in the center of the groove 3. The top of the buffer is close to the outer side wall. There are 3 bosses 4 on the edge of 1, in order to support the object, in order to increase the strength of the boss, increase the boss rib 5 at the bottom of the boss. The inner coaxial cylindrical side wall 2 is connected to the outer side wall 1 by ribs 6 . The top of the buffer structure has a spherical groove 3, and in order to increase the buffering effect, a circular hole is formed in the center of the groove 3.

[0025] Wherein, the coaxial hollow cylinder inside the buffer structure has a shorter length than the holl...

Embodiment 2

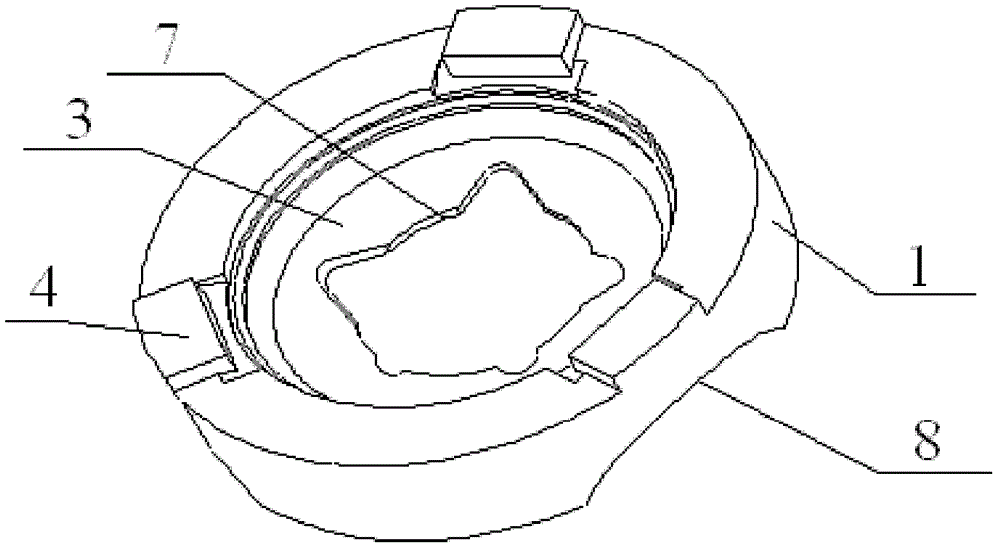

[0027] A new type of plastic buffer structure, the buffer structure such as Figure 3-4 shown. Made of nylon engineering plastics. It can be seen from the schematic diagram that the outside is a hollow cylinder, and there is a coaxial hollow cylinder inside. There is a groove 3 on the top of the buffer structure, and a special-shaped hole 7 is arranged in the center of the groove 3. The top of the buffer is close to the outer side wall. There are 3 bosses 4 on the edge of 1, in order to support object. In order to enhance the cushioning effect, three arc-shaped holes 8 are dug in the outer side wall 1 . Wherein, the length of the coaxial hollow cylinder inside the buffer structure is equal to the length of the hollow cylinder outside. The plastic buffer structure can be used as a packing structure for a compressor.

Embodiment 3

[0029] A plastic buffer structure, using continuous fiber reinforced polypropylene engineering plastics as material, the shape is hollow conical, with a coaxial hollow prism inside, a groove on the top of the buffer structure, and an opening in the center of the groove, Two bosses are arranged on the side wall of the groove.

[0030] Wherein, the outer wall of the buffer structure can be provided with an arc-shaped hole to increase the buffer performance, the length of the coaxial hollow prism is smaller than the outer hollow cone, and an arc-shaped hole to increase the buffer performance can be provided on the side wall of the coaxial hollow cone. The coaxial hollow cylinder is connected with the outer hollow conical side wall through the reinforcing rib.

[0031] The shape of the groove opened on the top of the buffer structure is W-shaped, and the shape of the opening on the groove is quadrilateral. The boss provided on the side wall of the groove protrudes to the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com