Novel disk type tension device

A tension device, disc type technology, applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of reduced effect, affecting the uniformity of yarn tension, and prone to plastic deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

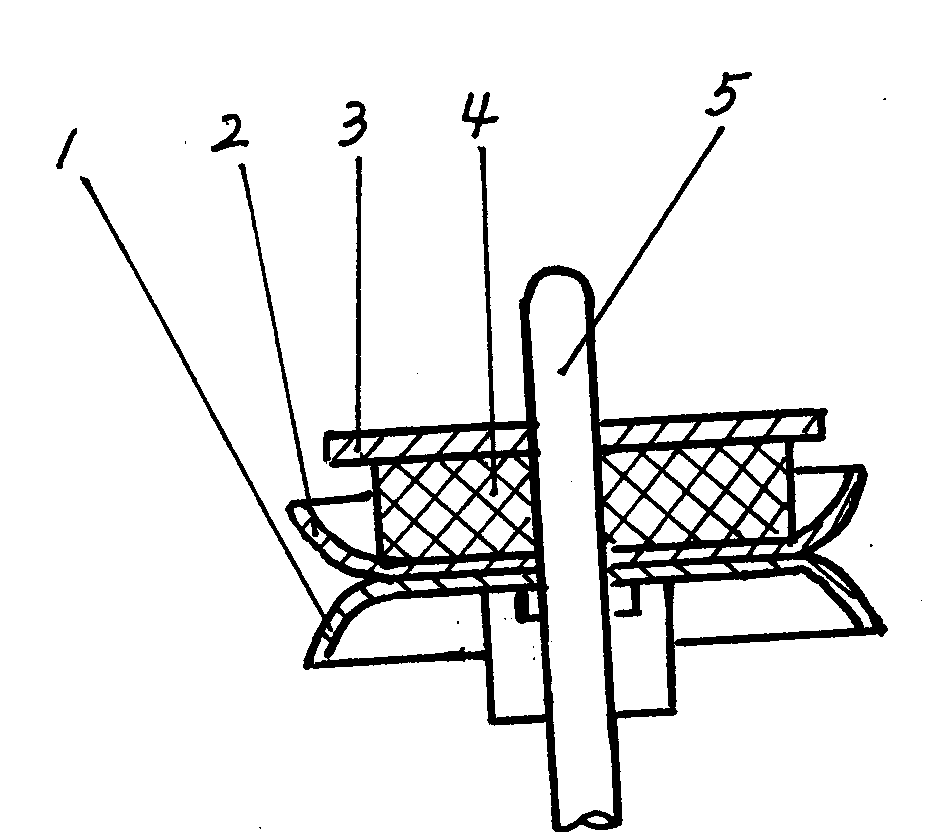

[0012] figure 1 Among them, the new disc tension device includes an upper tension disc 2, a lower tension disc 1 and a tension washer 3, and the upper tension disc 2, the lower tension disc 1 and the tension washer 3 are looped on the mandrel 5 , the upper tension disc 2 and the lower tension disc 1 are arranged oppositely, and the upper tension disc 2 is located above the lower tension disc 1, the tension washer 3 is located above the upper tension disc 2, and the tension washer 3 and the upper tension disc A cocoon-like polyester fiber washer 4 is installed between the disks 2, and the thickness of the cocoon-like polyester fiber washer 4 is between 5 mm and 8 mm. Cocoon cotton-like polyester fiber gasket 4 is made of polyester fiber heat-pressed into cocoon cotton shape by high technology. Cocoon cotton-like polyester fiber gasket 4 has good physical stability and resilience, and will not change due to temperature and humidity And expansion and contraction, no plastic defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com