Suspension system work station

A workstation and hanging technology, applied in the field of hanging systems, can solve the problems of insufficient working efficiency of the hanging system, slow processing speed, and large differences in complexity, so as to improve the scope of application and improve the working speed. , to ensure the effect of the completion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

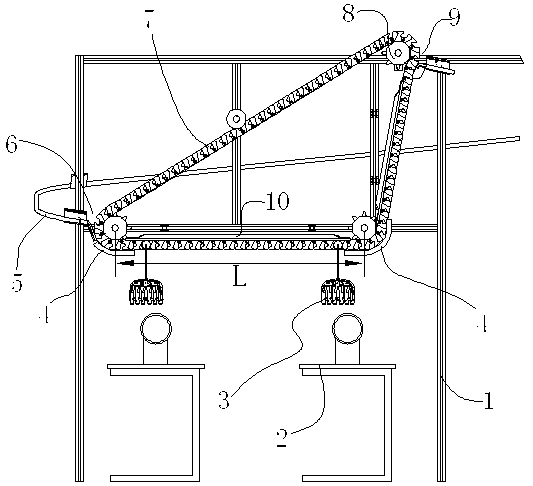

[0013] The structure of the work station of the hanging system of the present invention includes a support 1, a processing area is formed under the support 1, a machine platform 2 can be placed in the processing area, the operator sits in front of the machine platform 2, and uses the sewing machine on the machine platform 2 to sew The corresponding process of the product is completed. The hanging system includes a loop, and the hanger 3 can run on the loop. A transmission device is arranged on the support 1, the upper end of the transmission device extends to the loop line, and the lower end of the transmission device extends to the processing area. The hanger 3 can change its position between the loop line and the processing area through the conveying device. The hanging system is provided with a control computer, which controls the traveling direction of the hanging part 3 in the hanging system.

[0014] In order to increase the number of machines 2 placed in the processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com