Central permeation simulation core for laboratory experiments and preparation method thereof

A technology for permeation simulation and core simulation, which is applied in the field of medium permeation simulation core and its preparation for laboratory experiments, and can solve the problems of few quartz sand components, difficult to compact the base material, poor operability, etc., and achieves operability. Strong, low-cost, accurate and repeatable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a medium-permeability simulated rock core for indoor experiments, carried out according to the following steps:

[0026] A. Weigh six components of quartz sand and cement according to the design requirements of the simulated rock core, mix them together, and stir them evenly to form a core base material;

[0027] B. Clean the inner wall of the core tube, and then tighten one end of the core tube until there is no water or air leakage;

[0028] C. Fill the core base material that has been stirred and mixed evenly into the core tube several times until the core tube is filled. The amount of base material filled each time is 150-200g. After each filling, use a pressurizing device Pressurize the filled base material to 20-25MPa with the pressurizing rod, and release the pressure after maintaining the pressure for 20-30s;

[0029] D. After the core tube is filled with quartz sand, tighten the other end until there is no water or air leakage;

[0030]...

Embodiment 1

[0035] Example 1 - Preparation of 100 mD simulated core

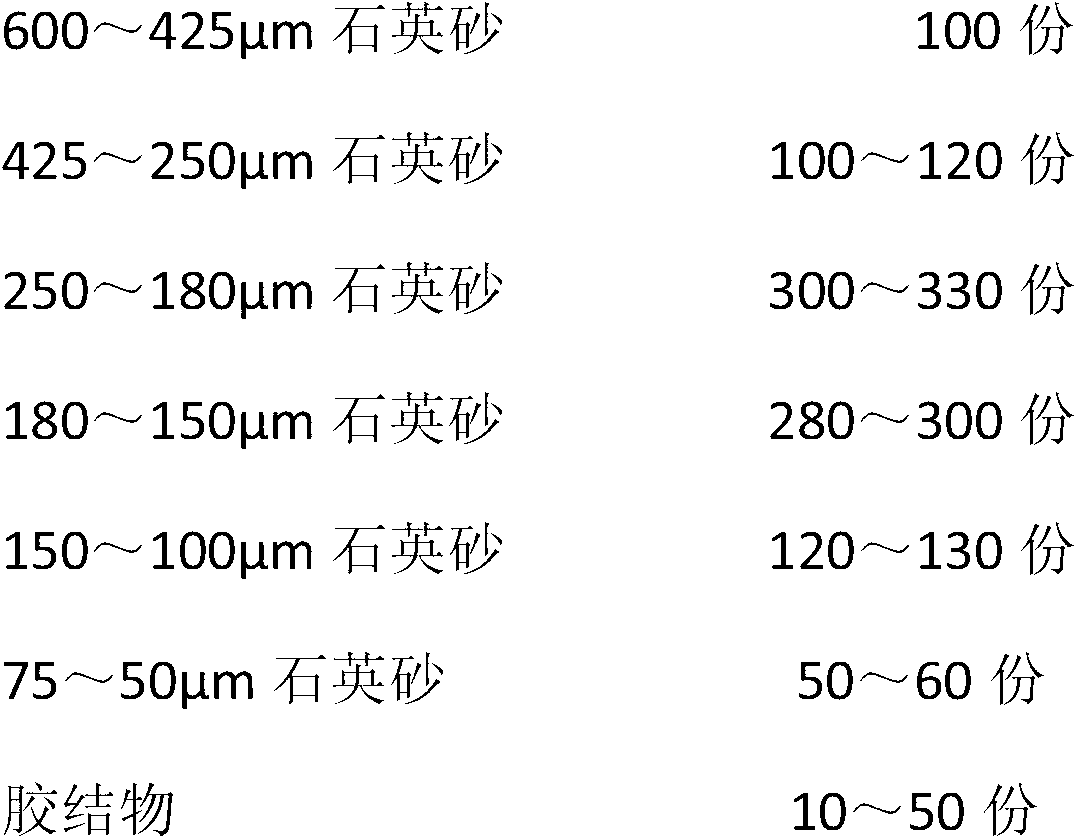

[0036] According to the physical simulation experiment in the microbial flooding laboratory, it is necessary to prepare a simulated core with a permeability of 100 mD. The components and weight ratio of the simulated core are as follows:

[0037]

[0038] The preparation method of medium permeability simulated rock core comprises the following steps:

[0039] A. Weigh the above six components of quartz sand and cement, mix them together, and stir them evenly to form a core base material. SiO in the quartz sand 2 The content is 99.5%, Fe 2 o 3 The content is 0.004%, and the cement is a silicate cement;

[0040] B. Clean the inner wall of the core tube, and then tighten one end of the core tube until there is no water or air leakage. The size of the core tube is Ф38mm×L600mm;

[0041] C. Fill the core base material that has been stirred and mixed evenly into the core tube several times until the core tube is filled...

Embodiment 2

[0046] Example 2 - Preparation of 50 mD simulated core

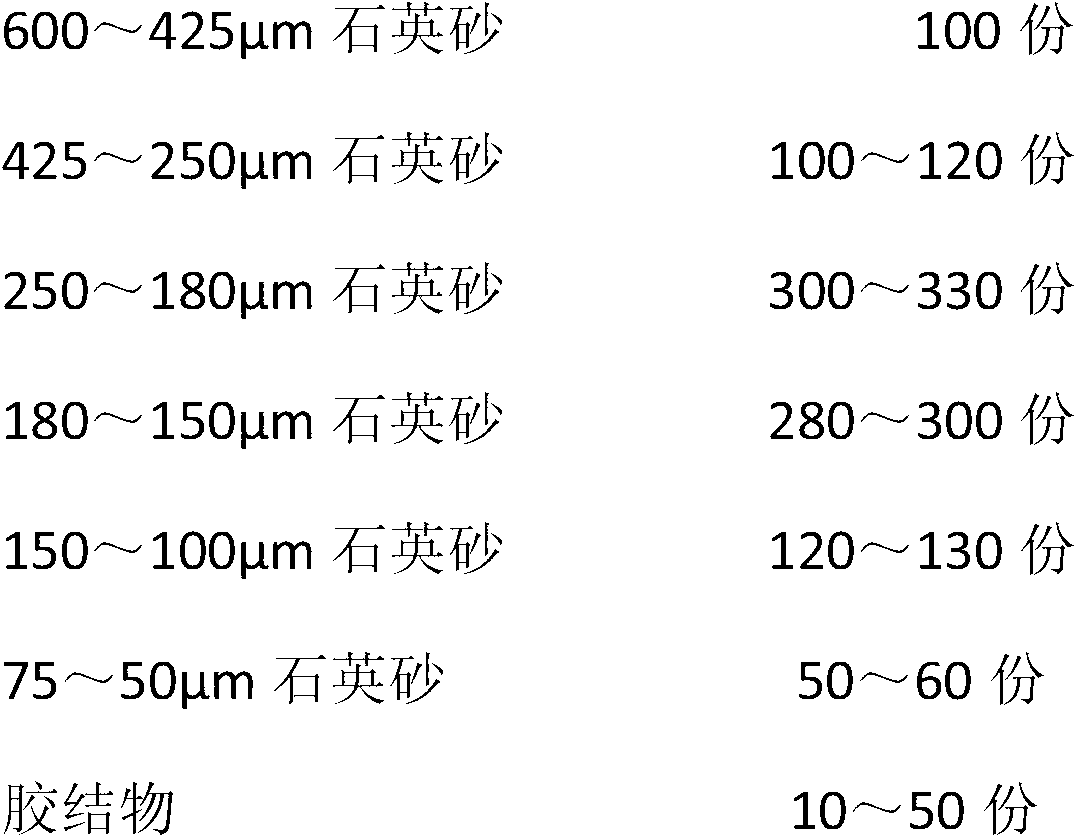

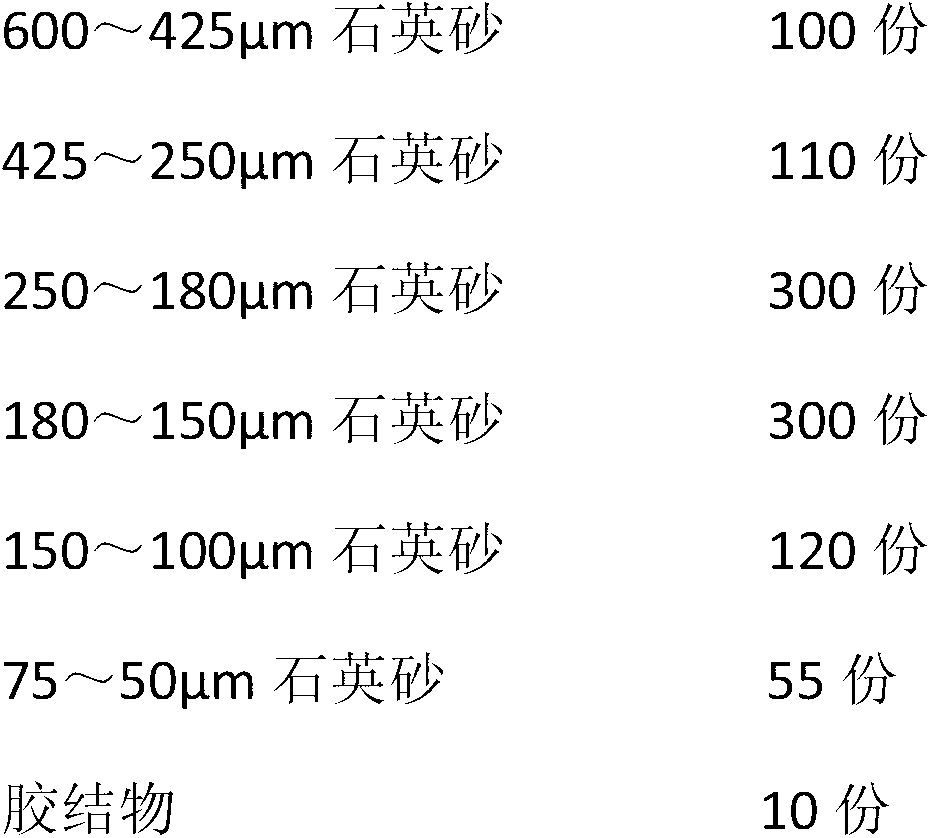

[0047] According to the physical simulation experiment in the microbial flooding laboratory, it is necessary to prepare a simulated core with a permeability of 50 mD. The components and weight ratio of the simulated core are as follows:

[0048]

[0049] The preparation method of medium permeability simulated rock core comprises the following steps:

[0050] A. Weigh the above six components of quartz sand and cement, mix them together, and stir them evenly to form a core base material. SiO in the quartz sand 2 The content is 99.5%, Fe 2 o 3 The content is 0.004%, and the cement is a silicate cement;

[0051]B. Clean the inner wall of the core tube, and then tighten one end of the core tube until there is no water or air leakage. The size of the core tube is Ф38mm×L600mm;

[0052] C. Fill the core base material that has been stirred and mixed evenly into the core tube several times until the core tube is filled. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com