Seawall silt soft base blasting orienting sliding and moving method

A silt and seawall technology, applied in marine engineering, soil protection, infrastructure engineering, etc., can solve the problems of poor orientation effect, uneven stone falling to the bottom, large post-construction settlement, etc., and achieve small post-construction settlement. , the effect of less explosive usage and precise sliding direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

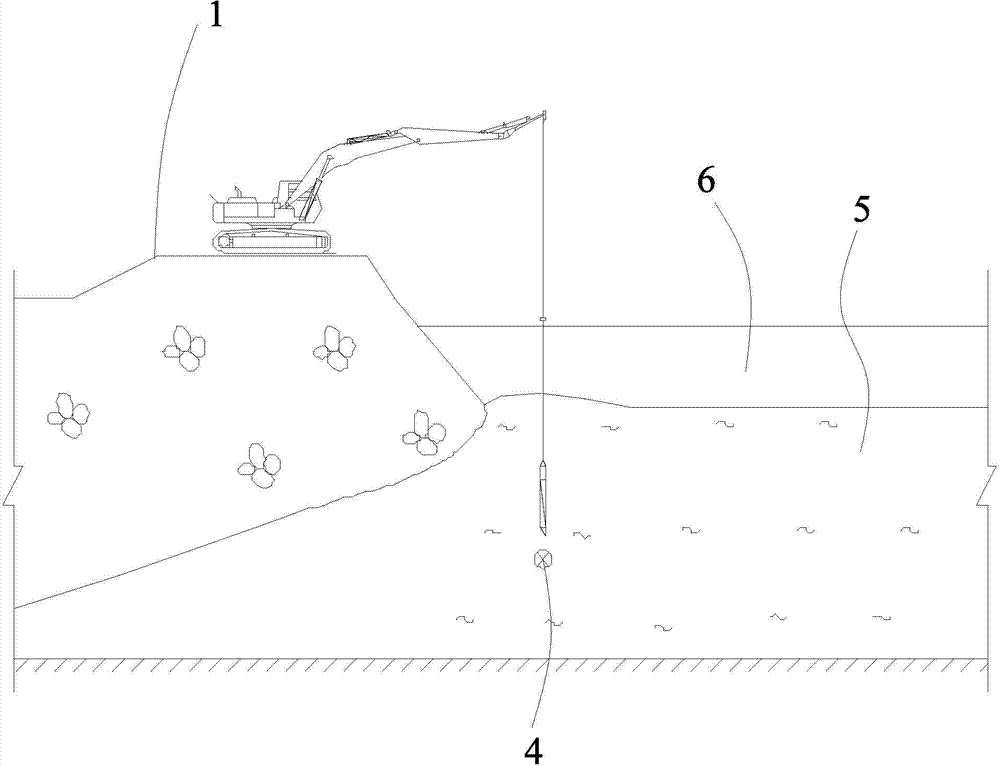

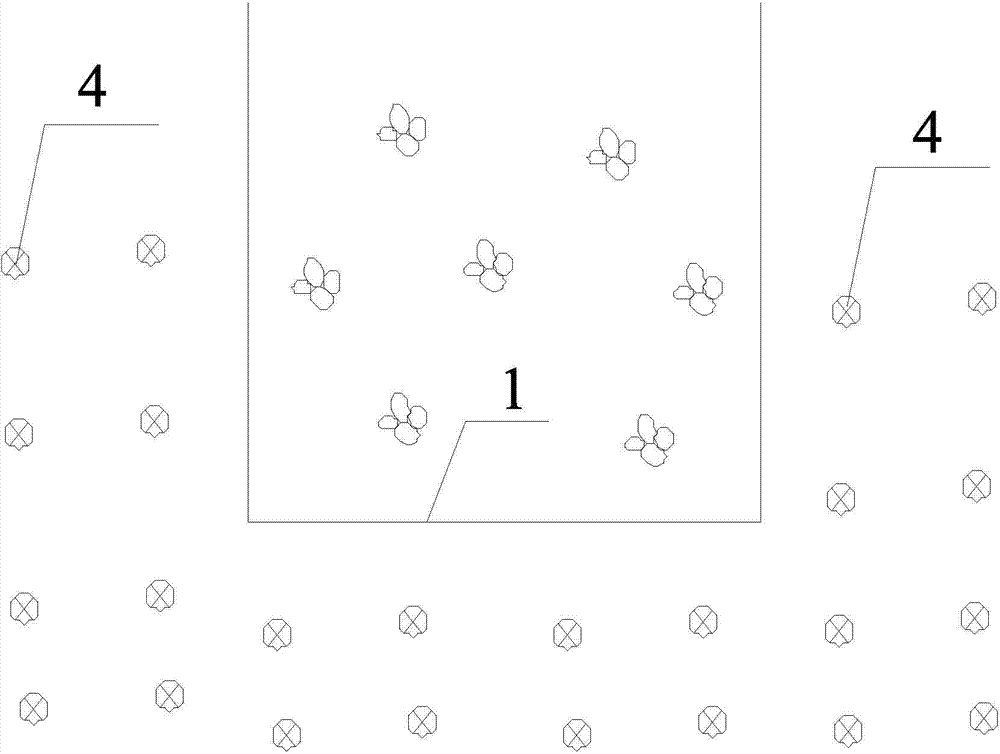

[0050] For the reclamation project of the breakwater construction site, the embankment is a slope type with a length of 252m. The thickness H of the silt layer 5 within the dike range m Between 10.7 and 13.35m, the depth of the water layer 6 above the silt is 10m, and the dike body throwing fill width is 14m.

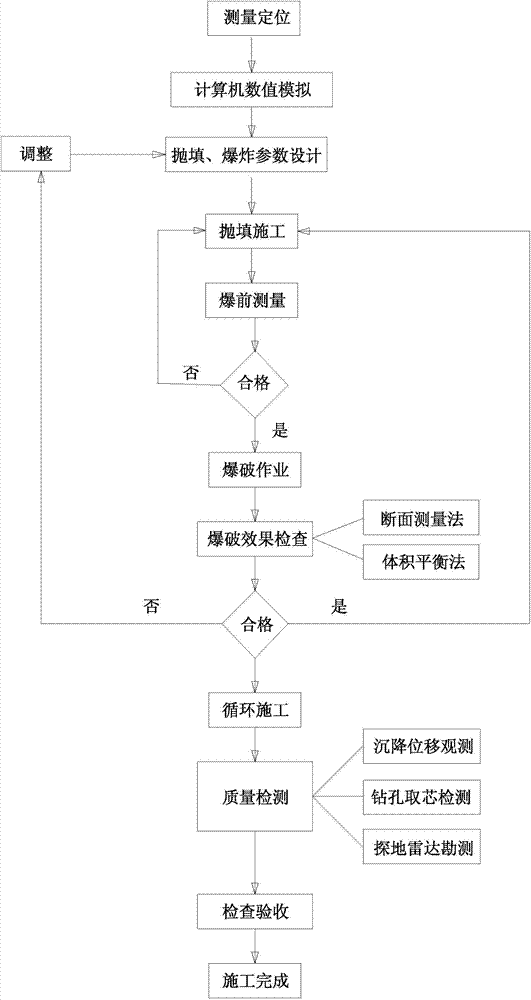

[0051] The specific construction steps are as figure 1 — Figure 5 Shown:

[0052] (1) Measurement and positioning: According to the existing coordinate control base point, GPS equipment is used for measurement and release, and the centerline control point of the seawall and the control sideline of the dumping and filling are respectively established on the sea surface and on land;

[0053](2) Throwing and filling construction: according to the construction design width and height of throwing and filling, throwing and filling shall be carried out. The weight of the throwing filler shall be mixed stone with a weight of 10-1000kg and a mud content of less than 10%. Fo...

Embodiment 2

[0061] The total length of the embankment is 3022.972m, and the volume of sludge treated is 722,000m 3 , with an average mud depth of about 11.0m and a maximum of 15.30m.

[0062] The specific construction steps are as figure 1 — Figure 5 Shown:

[0063] (1) Measurement and positioning: According to the existing coordinate control base point, GPS equipment is used for measurement and release, and the centerline control point of the seawall and the control sideline of the dumping and filling are respectively established on the sea surface and on land;

[0064] (2) Throwing and filling construction: according to the construction design width and height of throwing and filling, throwing and filling shall be carried out. The weight of the throwing filler shall be mixed stone with a weight of 10-1000kg and a mud content of less than 10%. For heightening treatment, the height of the embankment head is 1.0-2.5m, which is in the shape of a slope, and the height of both sides of th...

Embodiment 3

[0071] The seawall core blasting silt extrusion project consists of an arc-shaped embankment with a total length of about 1,700m. The amount of underwater silt processed by blasting and directional sliding is 1.66 million m 3 , the average depth of the silt layer 5 is 8m, the depth of the covered water layer 6 is 5m, and the maximum thickness is about 25m.

[0072] The specific construction steps of each embankment are as follows: figure 1 — Figure 5 Shown:

[0073] (1) Measurement and positioning: According to the existing coordinate control base point, GPS equipment is used for measurement and release, and the centerline control point of the seawall and the control sideline of the dumping and filling are respectively established on the sea surface and on land;

[0074] (2) Throwing and filling construction: according to the construction design width and height of throwing and filling, throwing and filling shall be carried out. The weight of the throwing filler shall be mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com