Slipping loading machine perpendicular lift device

A skid steer loader and vertical lift technology, which is applied in mechanically driven excavators/dredgers, etc., can solve the problems of poor mechanical properties and narrow application scope of skid steer loader, so as to improve the layout and the application scope. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

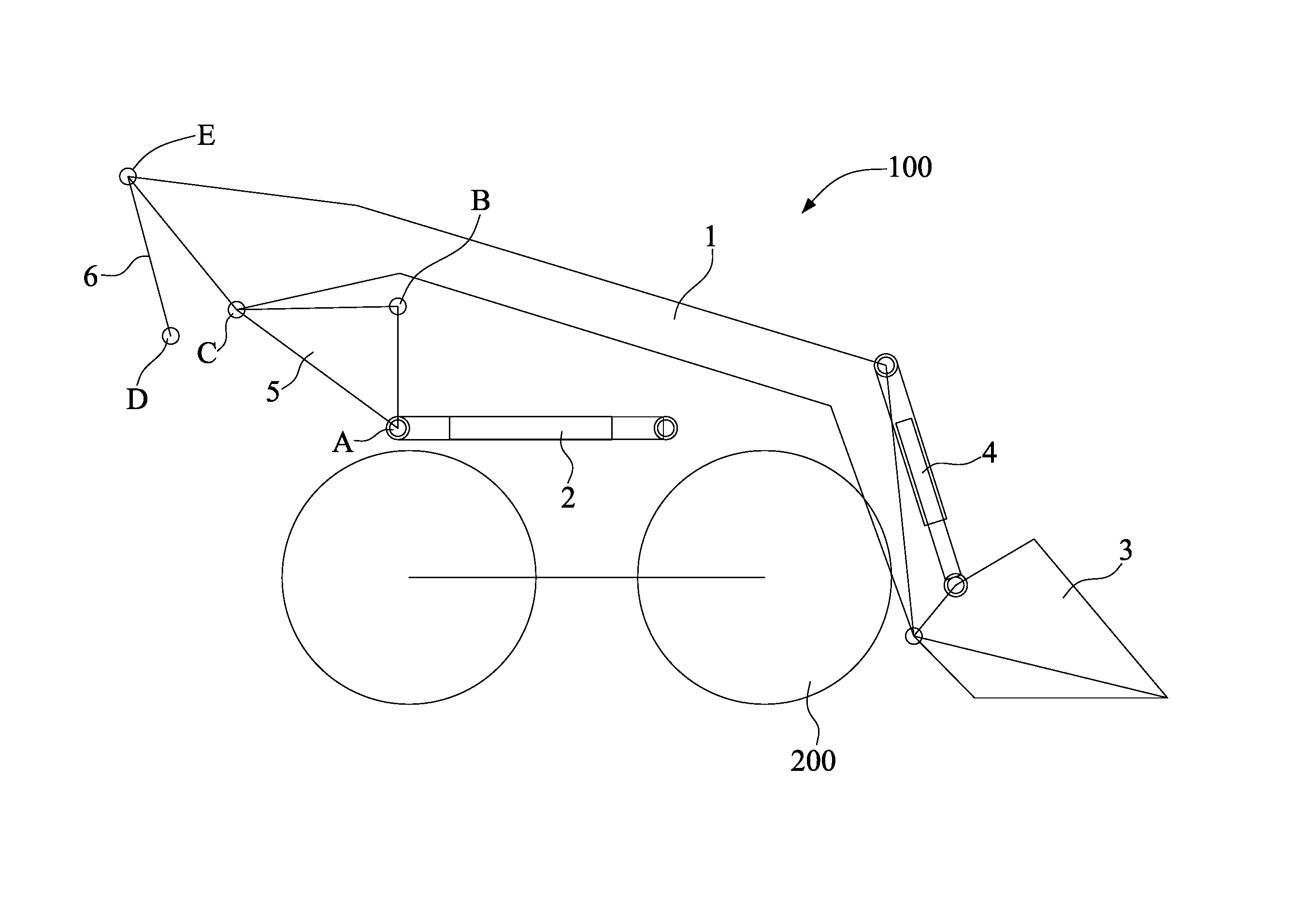

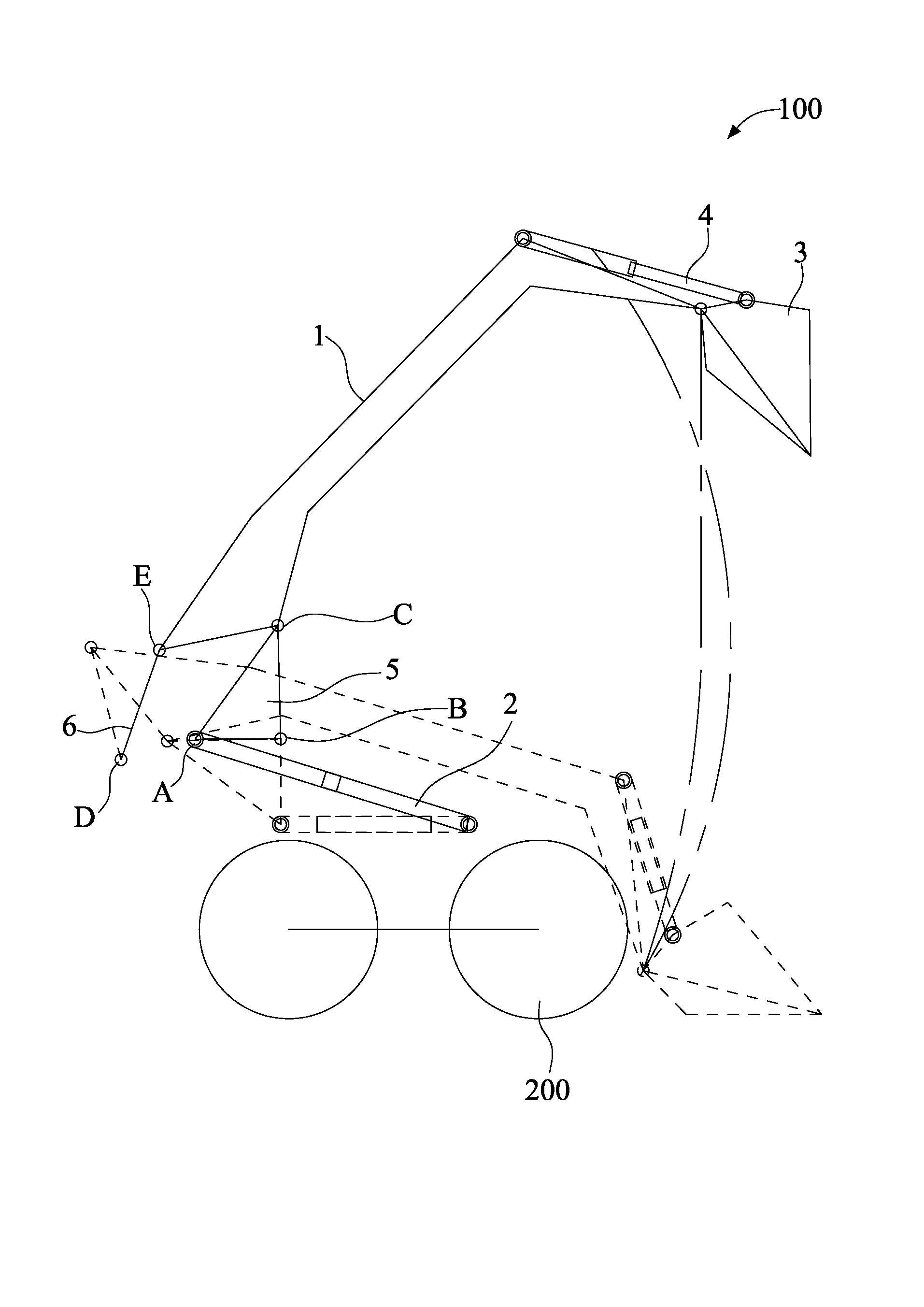

[0029] like figure 1 and figure 2 As shown, it is a preferred embodiment of the present invention related to a vertical lifting device 100 for a skid steer loader. The vertical lifting device 100 includes a vehicle frame (not shown in the figure), boom 1, boom driving mechanism 2, The bucket 3 and the bucket driving mechanism 4 are both arranged at the front end of the boom 1, and one end of the boom driving mechanism 2 is hingedly connected with the vehicle frame, and the sliding movement is also shown in the figure Wheels 200 for the loader.

[0030] The improvement of the present invention is that: the vertical lifting device 100 also includes a first rocker arm 5 and a second rocker arm 6, and the first rocker arm 5 has a first hinge point A, a second hinge point B and a non-overlapping first hinge point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com