Patents

Literature

40 results about "Radiation Leak" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Condensed tungsten composite material and method for manufacturing and sealing a radiation shielding enclosure

Materials and methods of manufacturing radiation shielded enclosures is presented that may replace the use of lead, granite and other undesirable materials and manufacturing methods. The present invention provides a high-density radiation shielding enclosure manufactured using a fiberglass lay-up or pressure spaying process and tungsten powder. The method of manufacture may include applying a tungsten powder in an epoxy, caulking, sealant, adhesive or elastomeric compound to the radiation shielding enclosure in order to seal any cracks, holes, joints or other radiation leaks.

Owner:AGILENT TECH INC

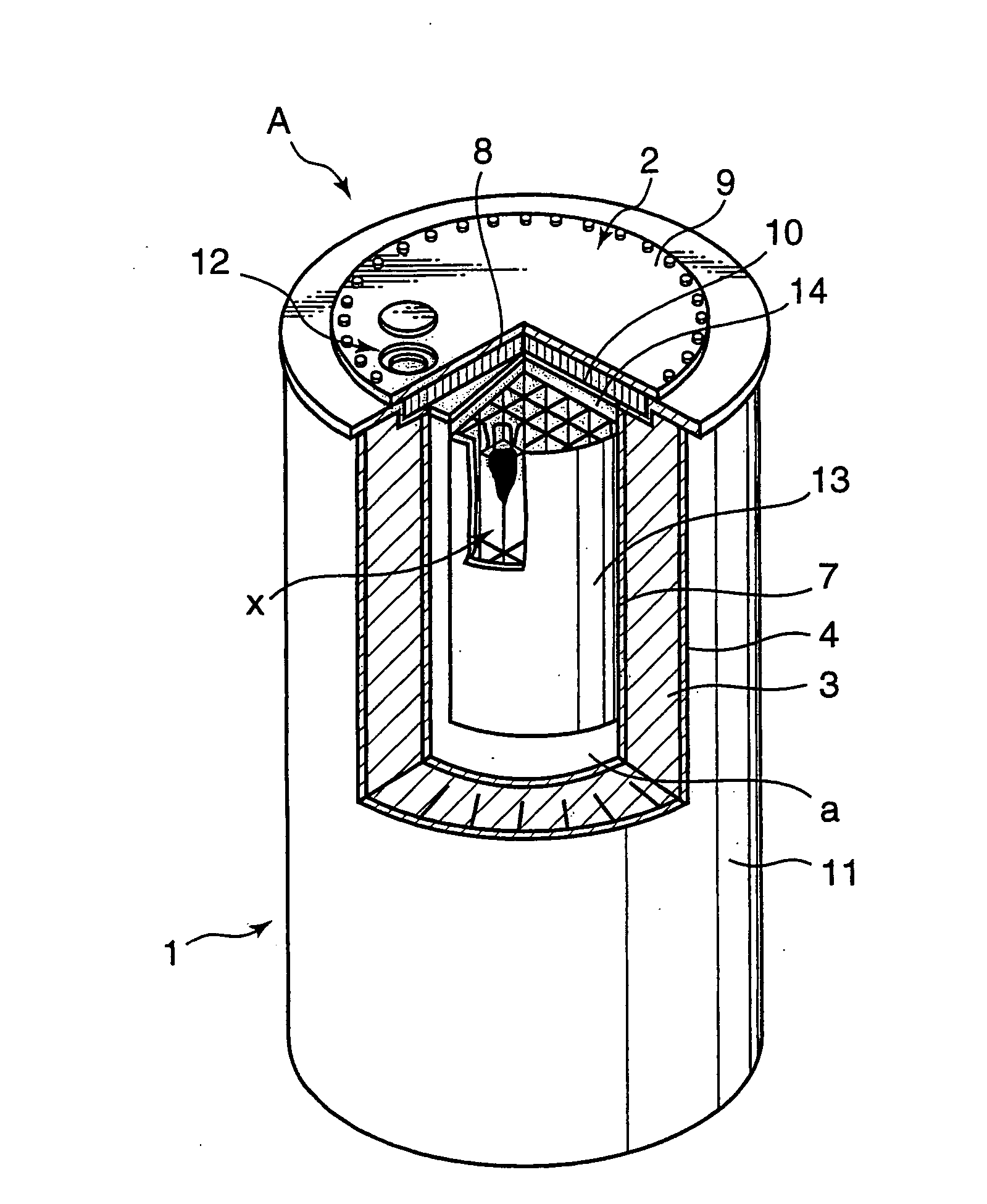

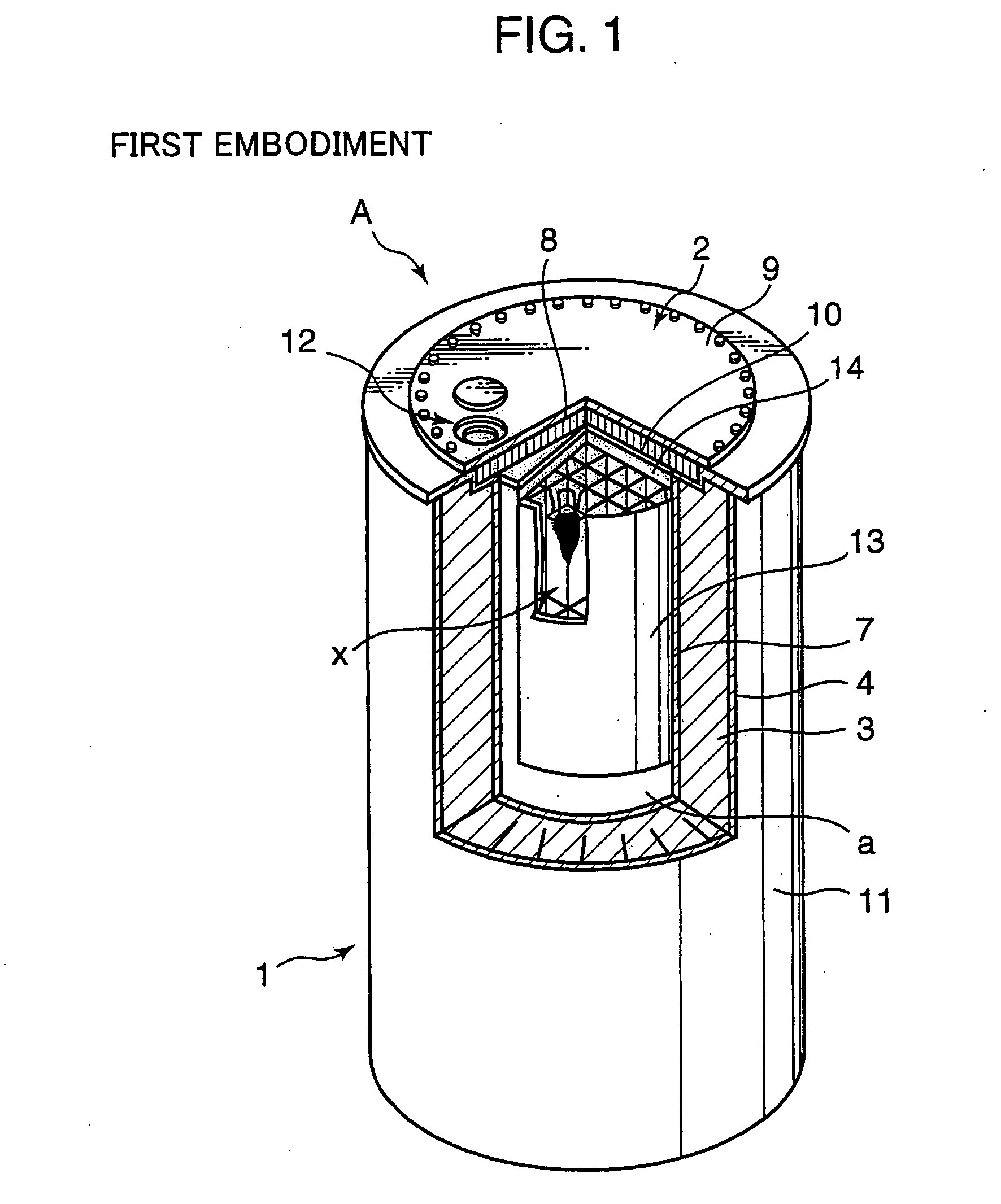

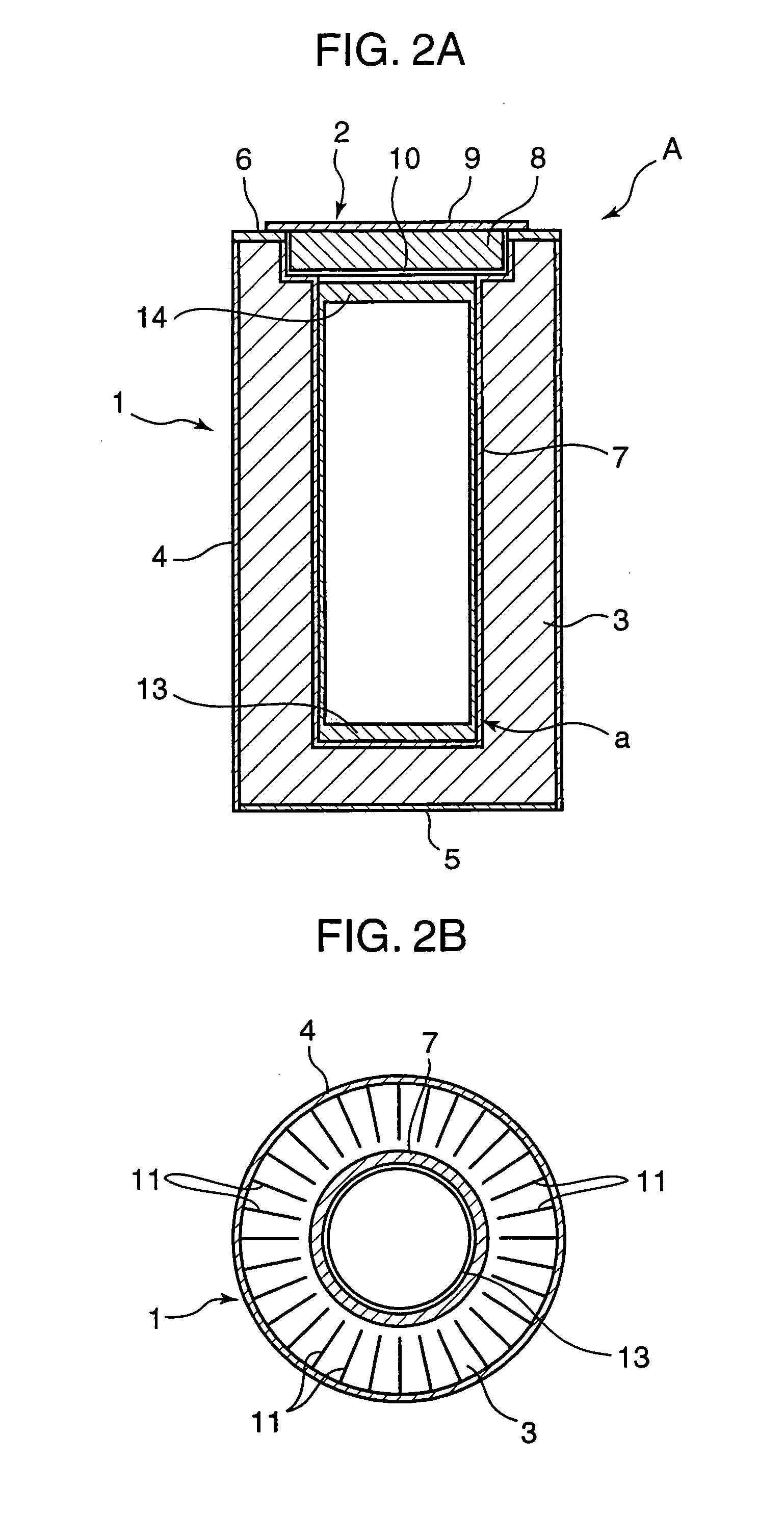

Concrete cask and method for manufacturing thereof

It is an object of the present invention to obtain a containment concrete cask which has heat removal capacity maintained at the conventional level or beyond it and which prevents radiation from leaking to the outside. In a concrete cask, a shielding body composed of concrete and heat transfer fins made from metal are provided between an inner shell and an outer shell made from metal, and an accommodation portion for accommodating a radioactive substance is provided inside the inner shell. The accommodation portion has a containment structure to be insulated from the outside of the cask. In the heat transfer fins, the portions thereof at the outer shellside are provided in contact with the outer shell and the portions thereof at the inner shell side are cut so as to form a separation portion with respect to the inner shell.

Owner:KOBE STEEL LTD +1

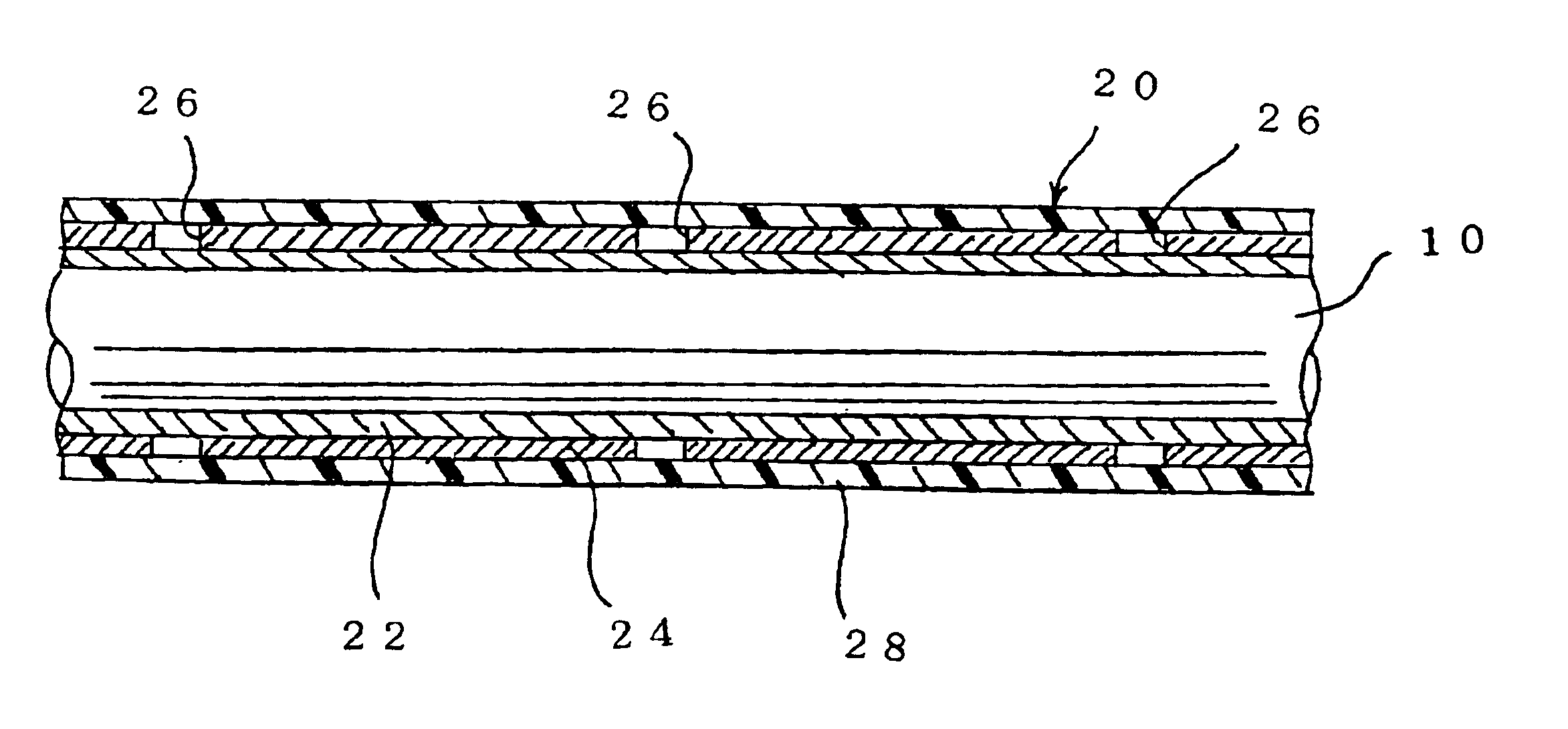

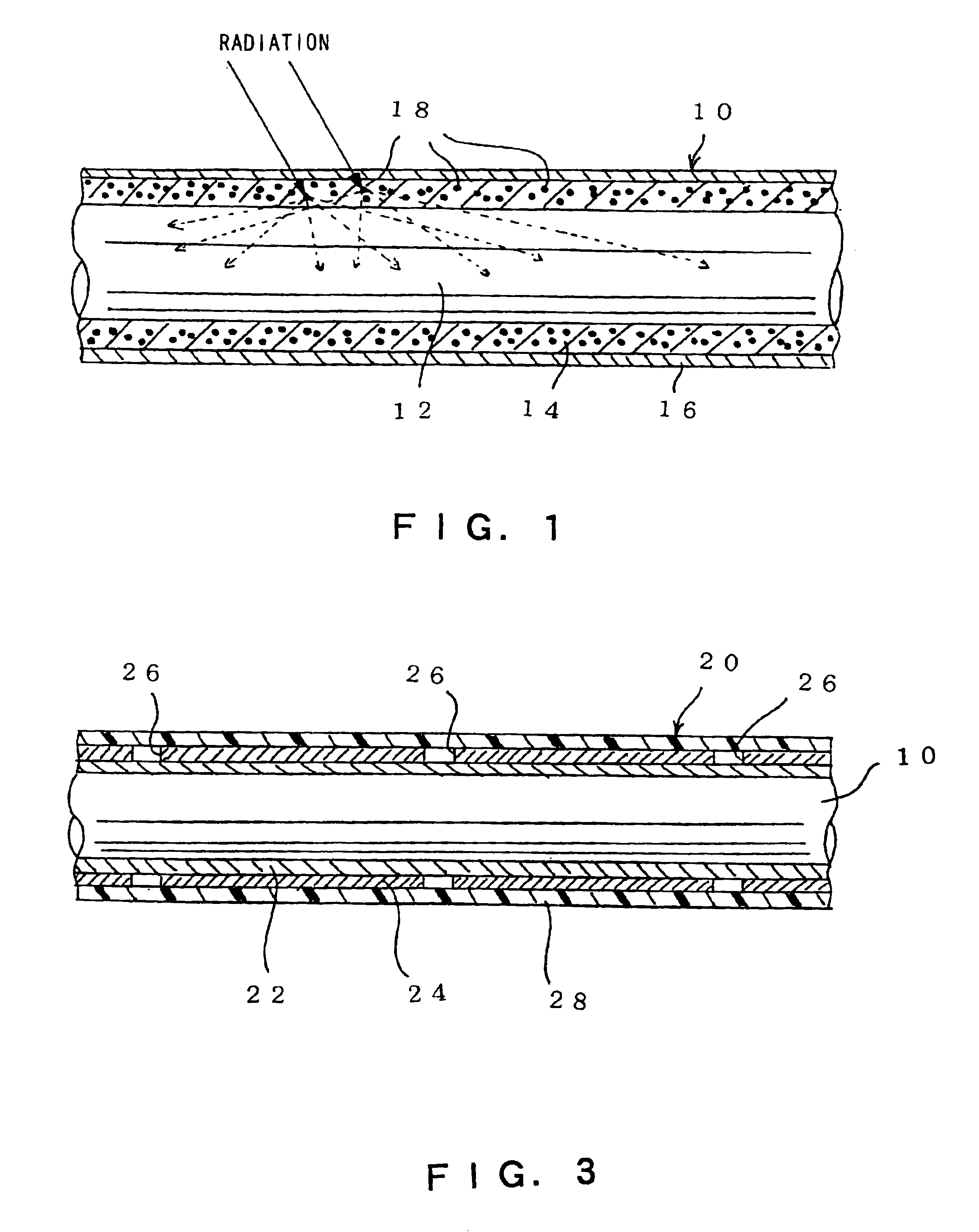

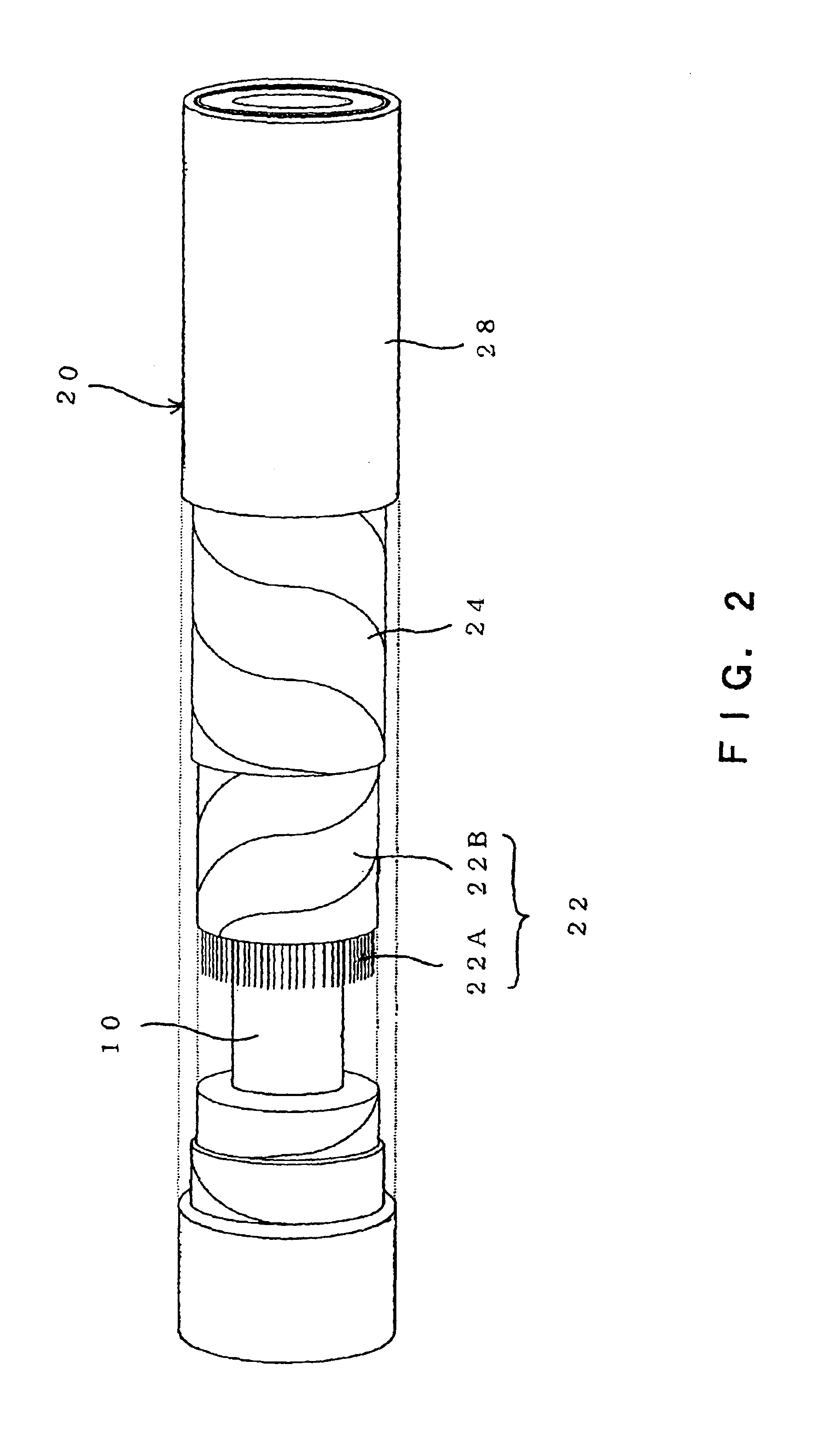

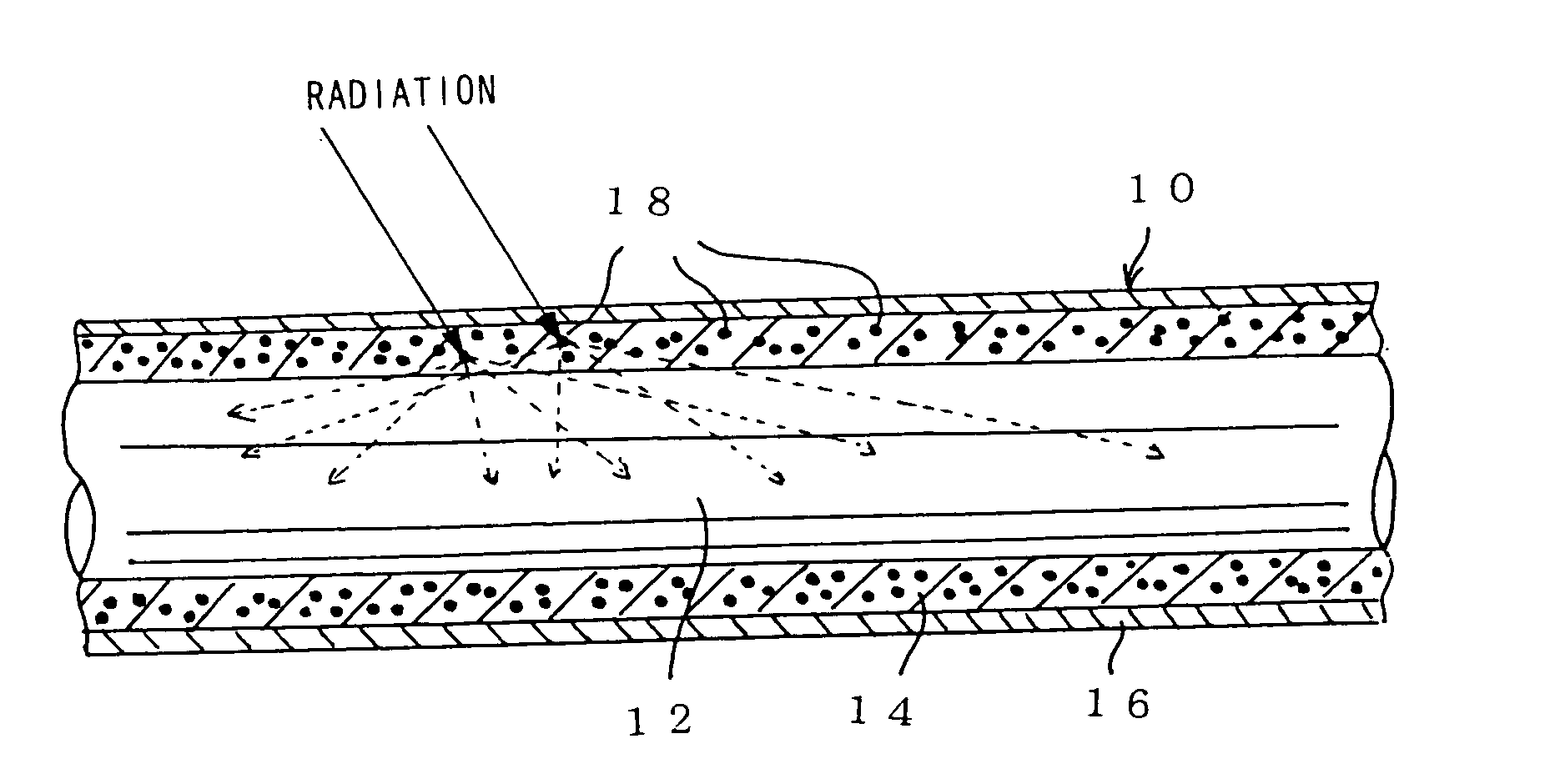

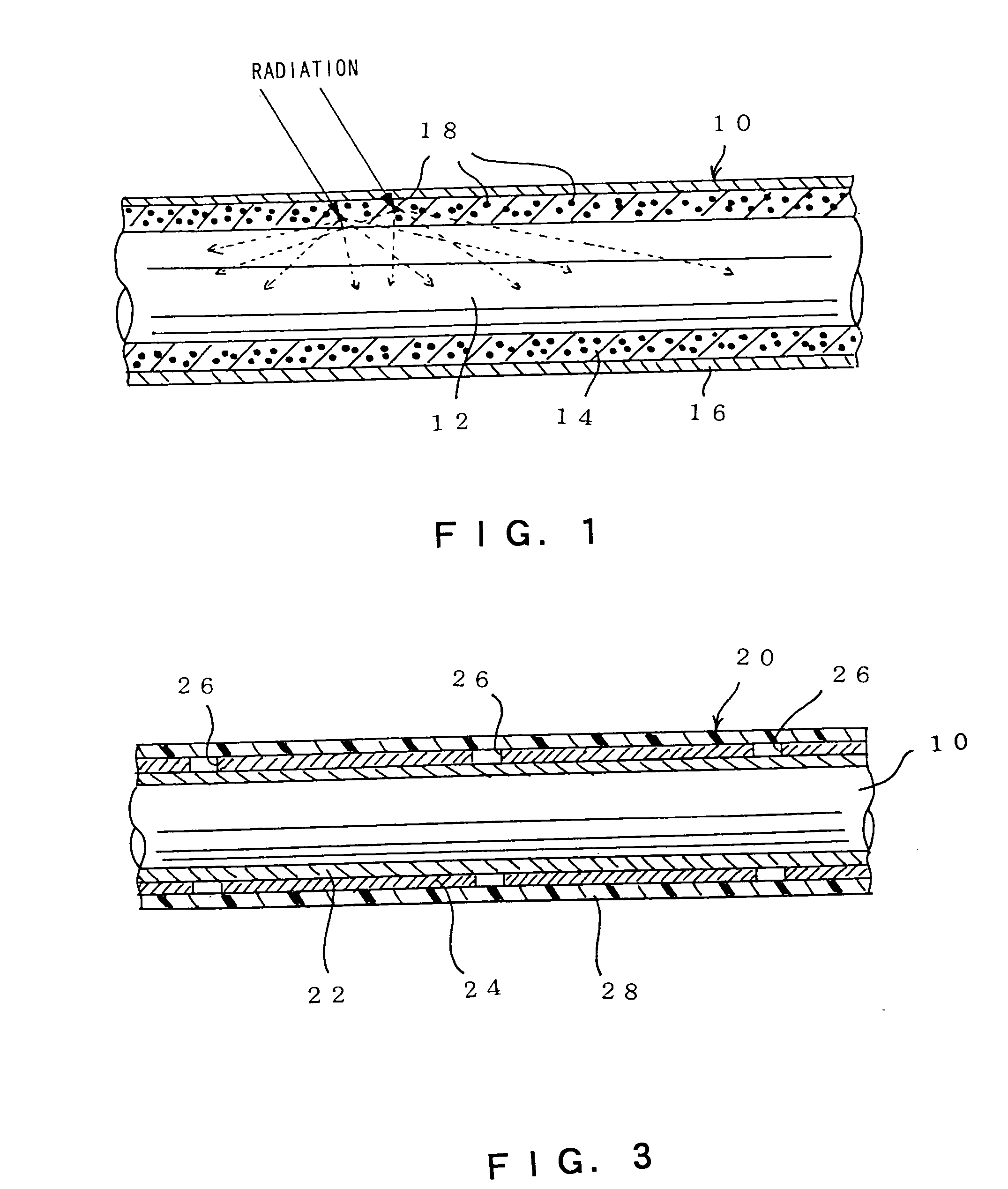

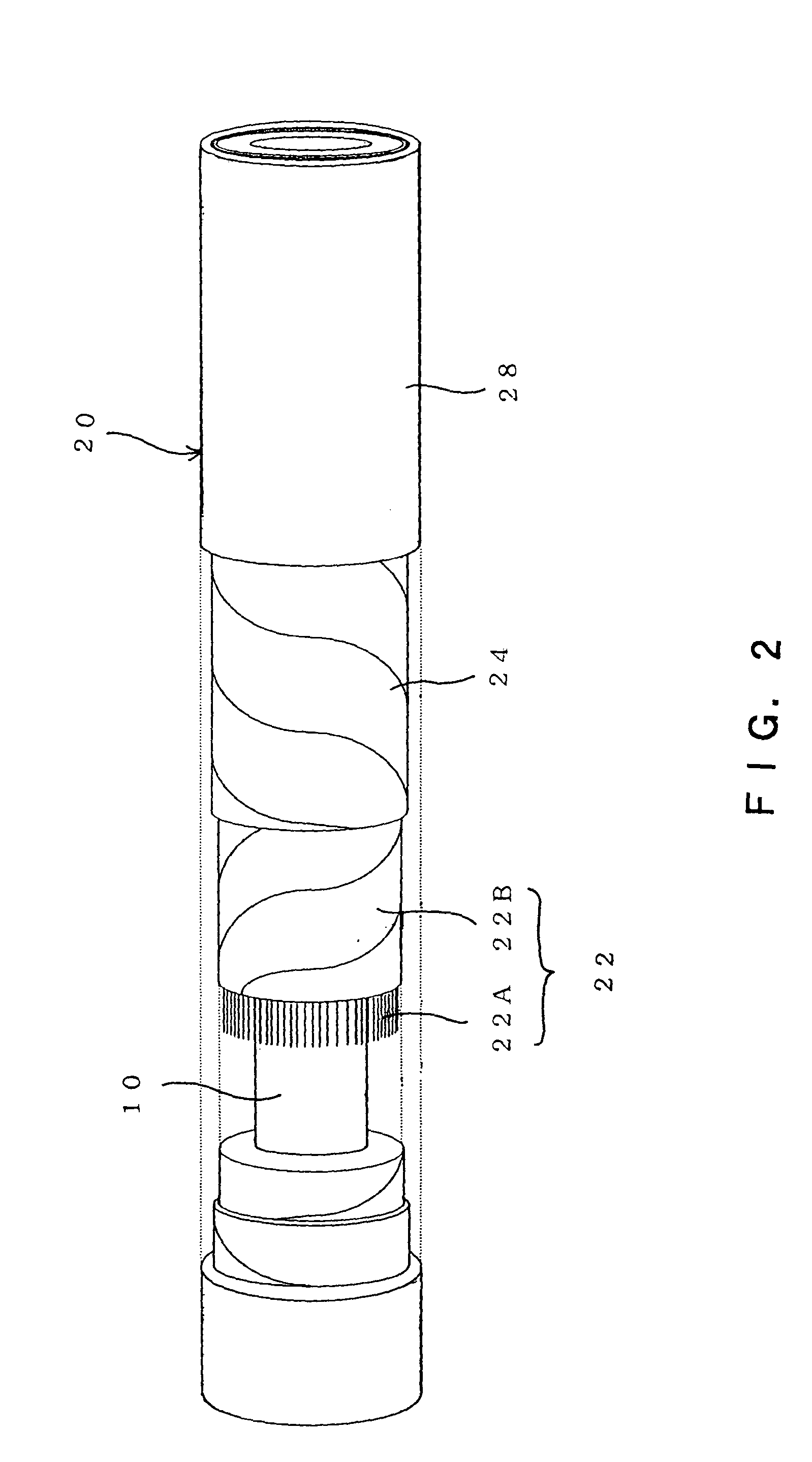

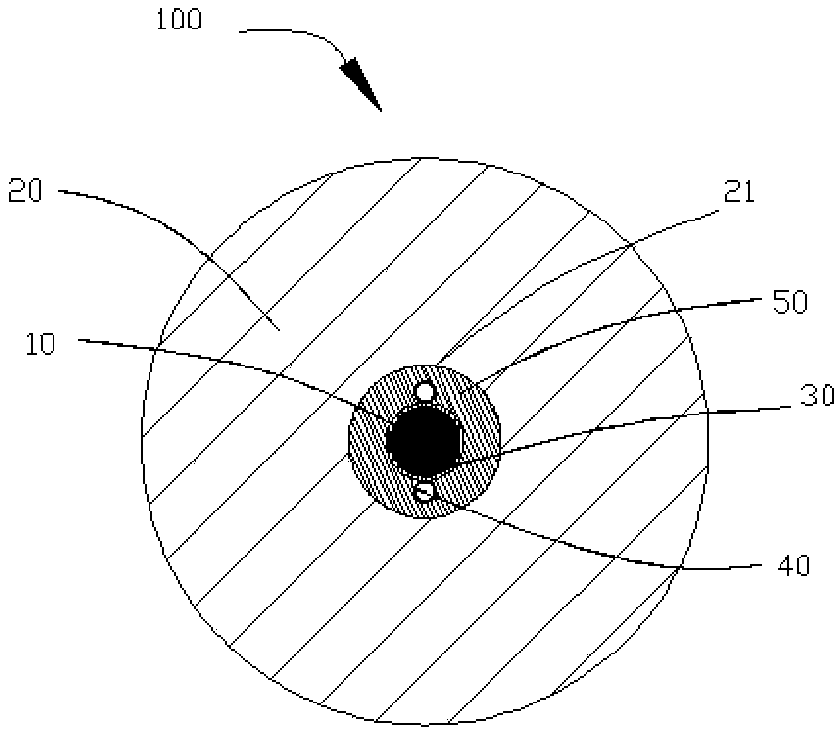

Optical fiber, optical fiber cable, and radiation detecting system using such

InactiveUS6859607B2Low costGlass optical fibreOptical fibre with multilayer core/claddingPhotoelectric conversionOpto electronic

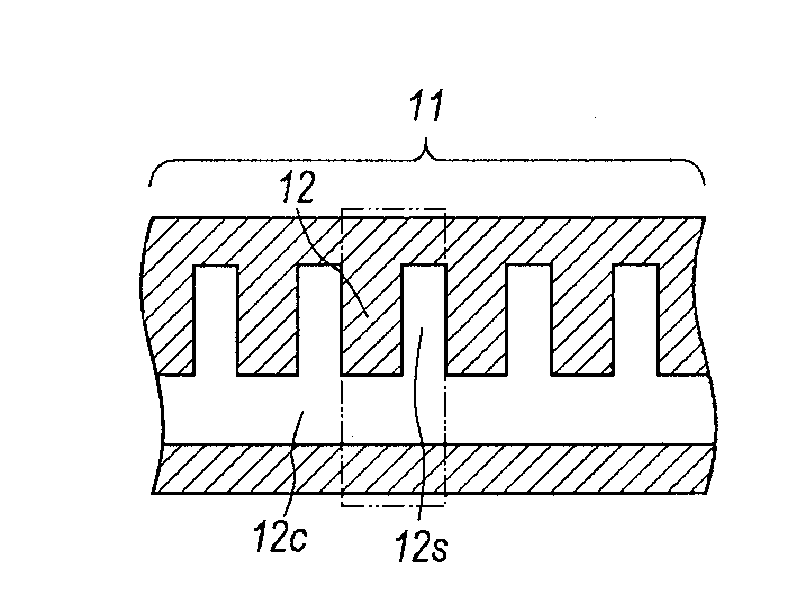

The present invention provides an optical fiber, an optical fiber cable and a radiation detecting system at a low cost. Further, the radiation detecting system is provided which can adequately monitor the radiation leak without delay. The optical fiber cable comprises: an optical fiber including; a core 12 having lightwave guide property and extending along one direction; a clad layer 14 covering over a peripheral surface of the core 12; and a scintillator material dispersed in the clad layer 14 and emitting light when radiation is applied, a radiation-shielding layer 24 covering substantially over a periphery of the optical fiber10, and a gap 26 located in at least one part of the radiation-shielding layer 24. The radiation detecting system comprises an optical fiber cable 20 adapted to emit light at a region where radiation is applied and transmitting the emitted light, photoelectric conversion means 32 connected to at least one end of the optical fiber cable 20, and processing means 38 detecting when radiation is applied in accordance with an output signal of the photoelectric conversion means 32.

Owner:WIRED JAPAN

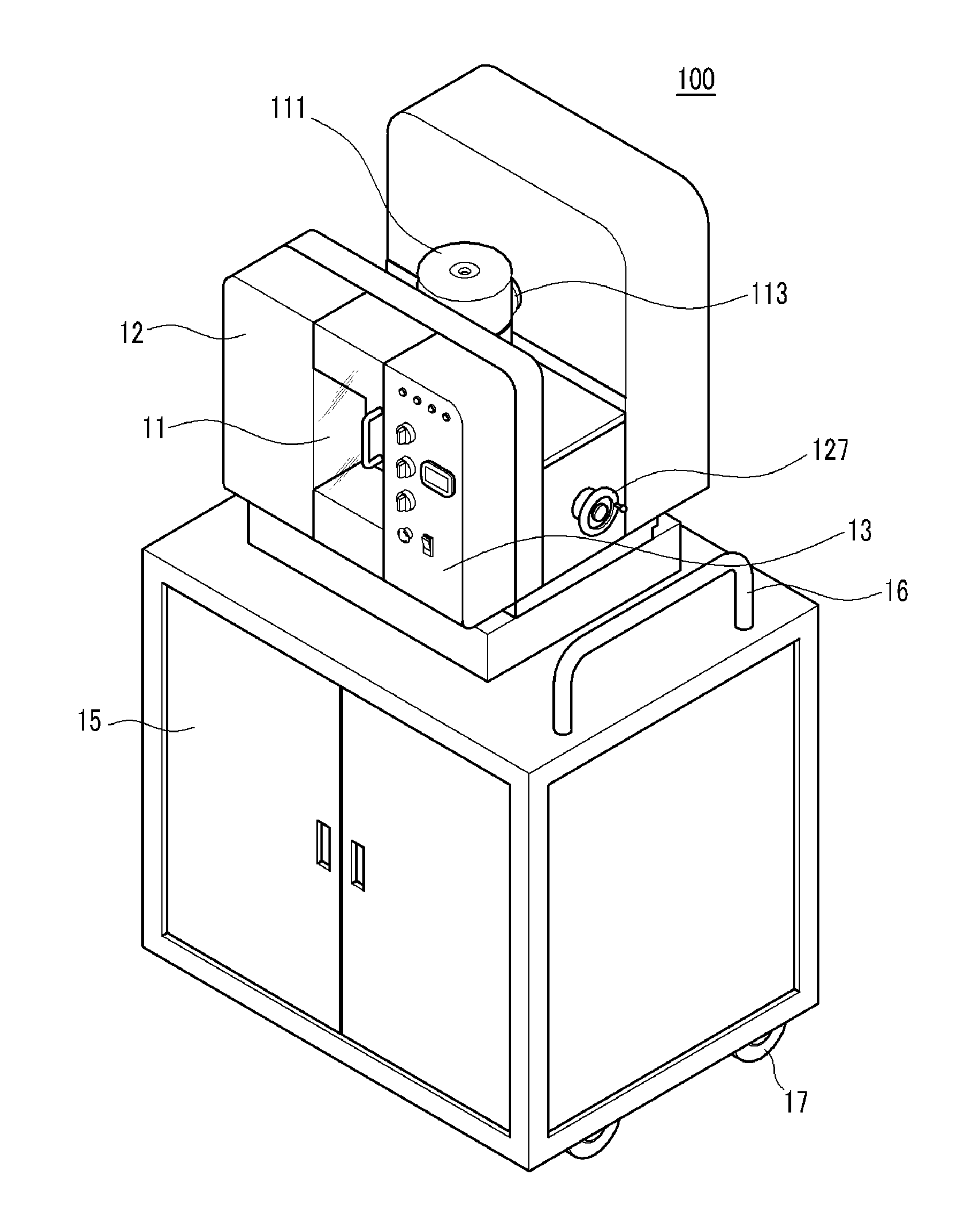

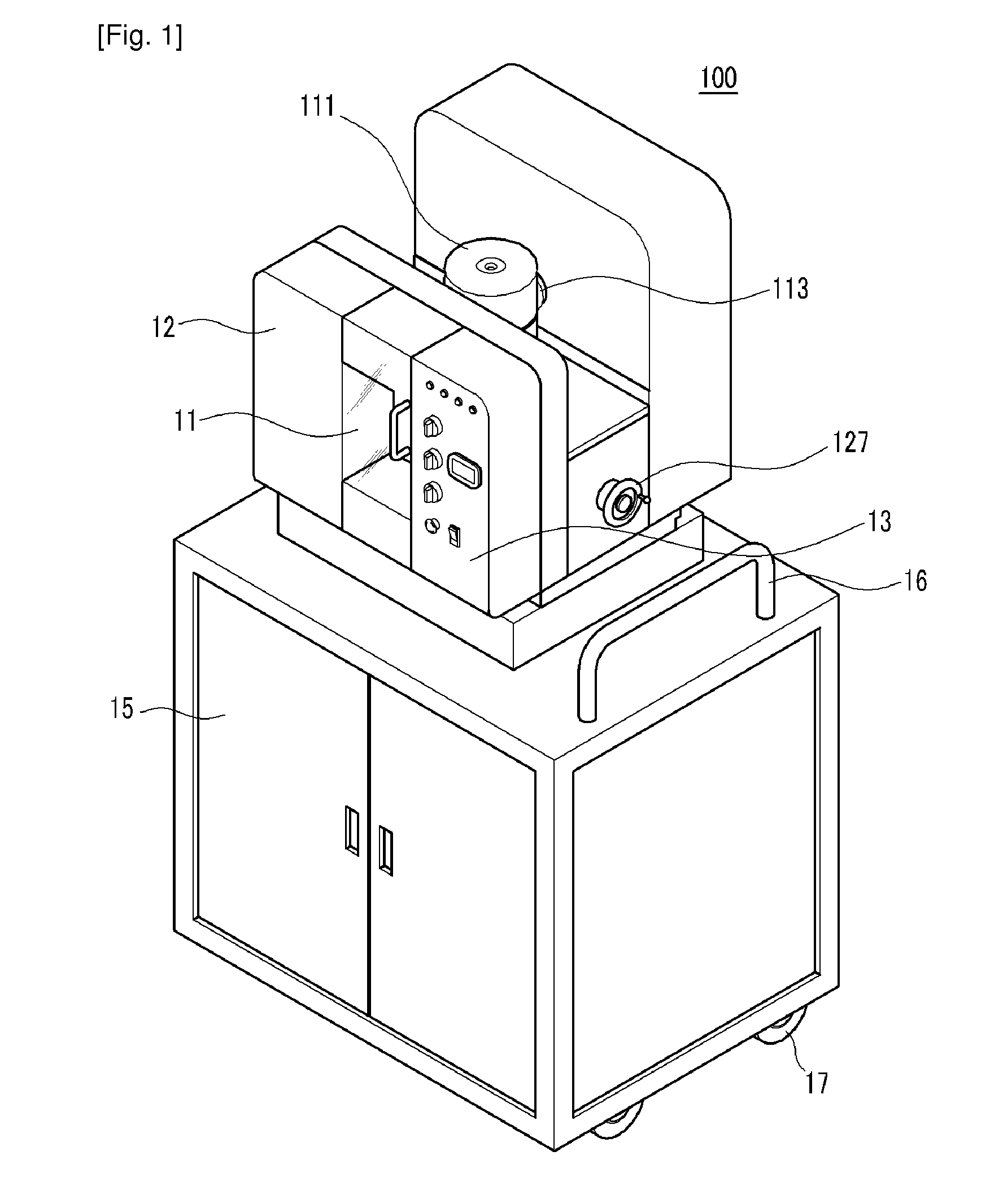

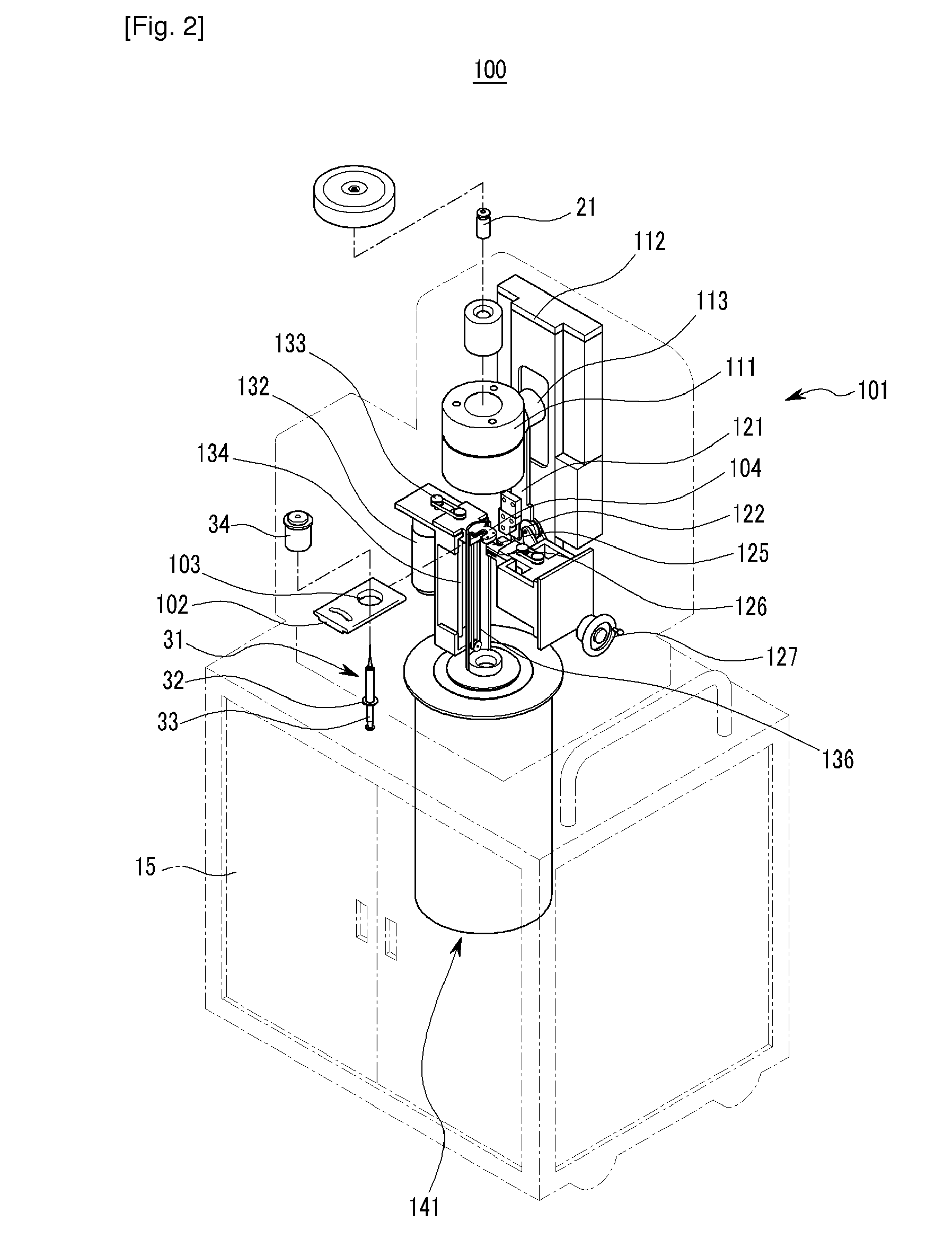

System for dispensing radio-pharmaceuticals and measuring radiation dosage of it

InactiveUS20100331600A1Preventing and minimizing riskProcess stabilityIsotope delivery systemsPharmaceutical containersRadiation exposureRadiation Leak

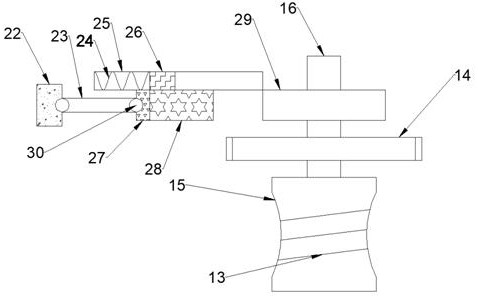

The present invention provides a system for dispensing radiopharmaceuticals and measuring a radiation dosage thereof. In the system, the operation of dispensing a predetermined dose of radiopharmaceuticals from a vial (21) to an syringe (31) and the operation of measuring a radiation dosage of the radiopharmaceuticals dispensed to the syringe can be sequentially conducted without a risk of radiation leaking. Therefore, the system can markedly reduce the frequency of radiation exposure and the radiation exposure dose. Furthermore, when the syringe is moved downwards from a radiopharmaceutical dispensing apparatus (101) into a radiation dosage measuring apparatus (141) to measure a radiation dosage, the filling opening of the vial is displaced from a position aligned with the syringe, thus preventing radiopharmaceuticals remaining in the vial from affecting the measurement of the radiation dosage of the syringe.

Owner:PARK HYUN MI +1

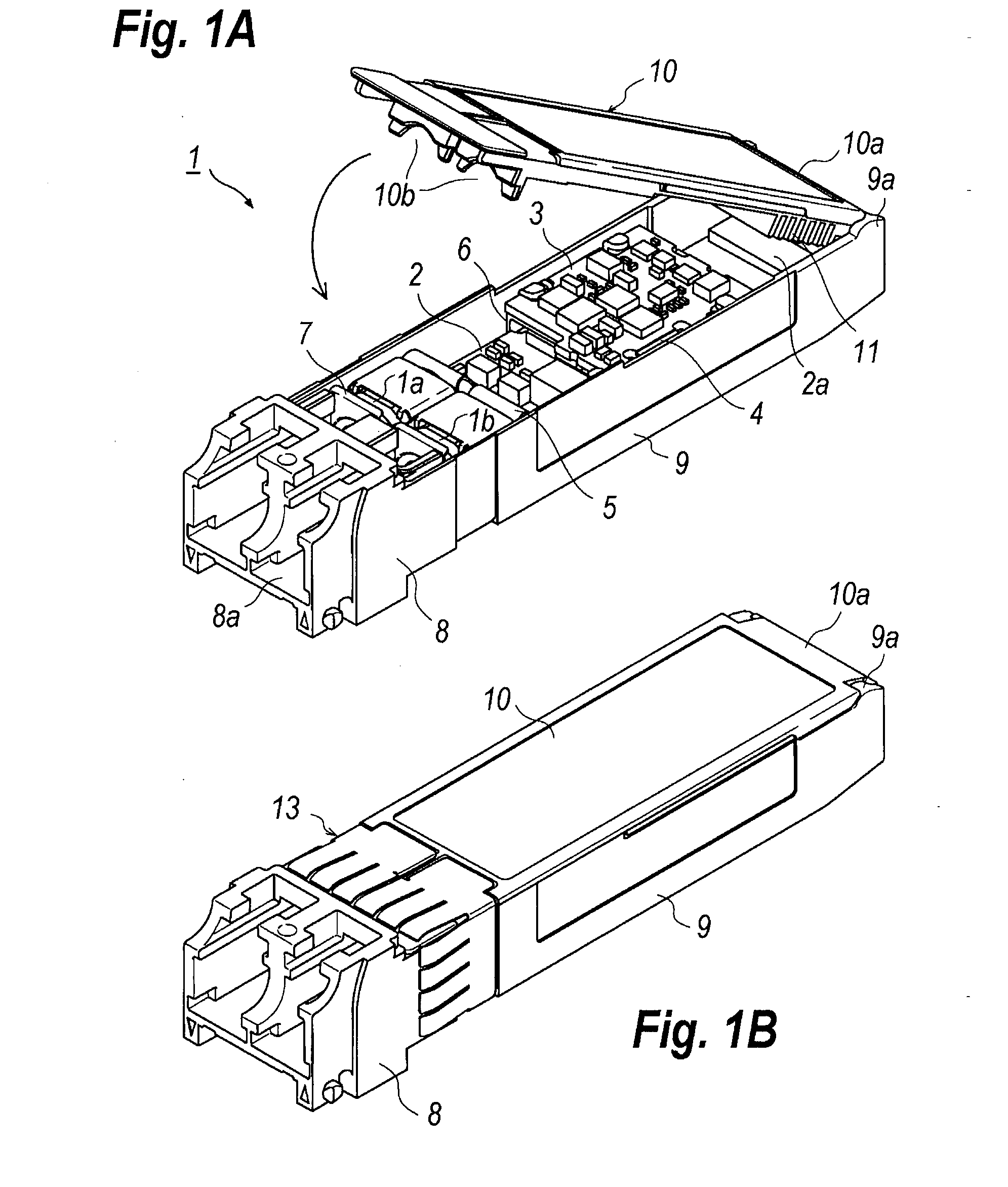

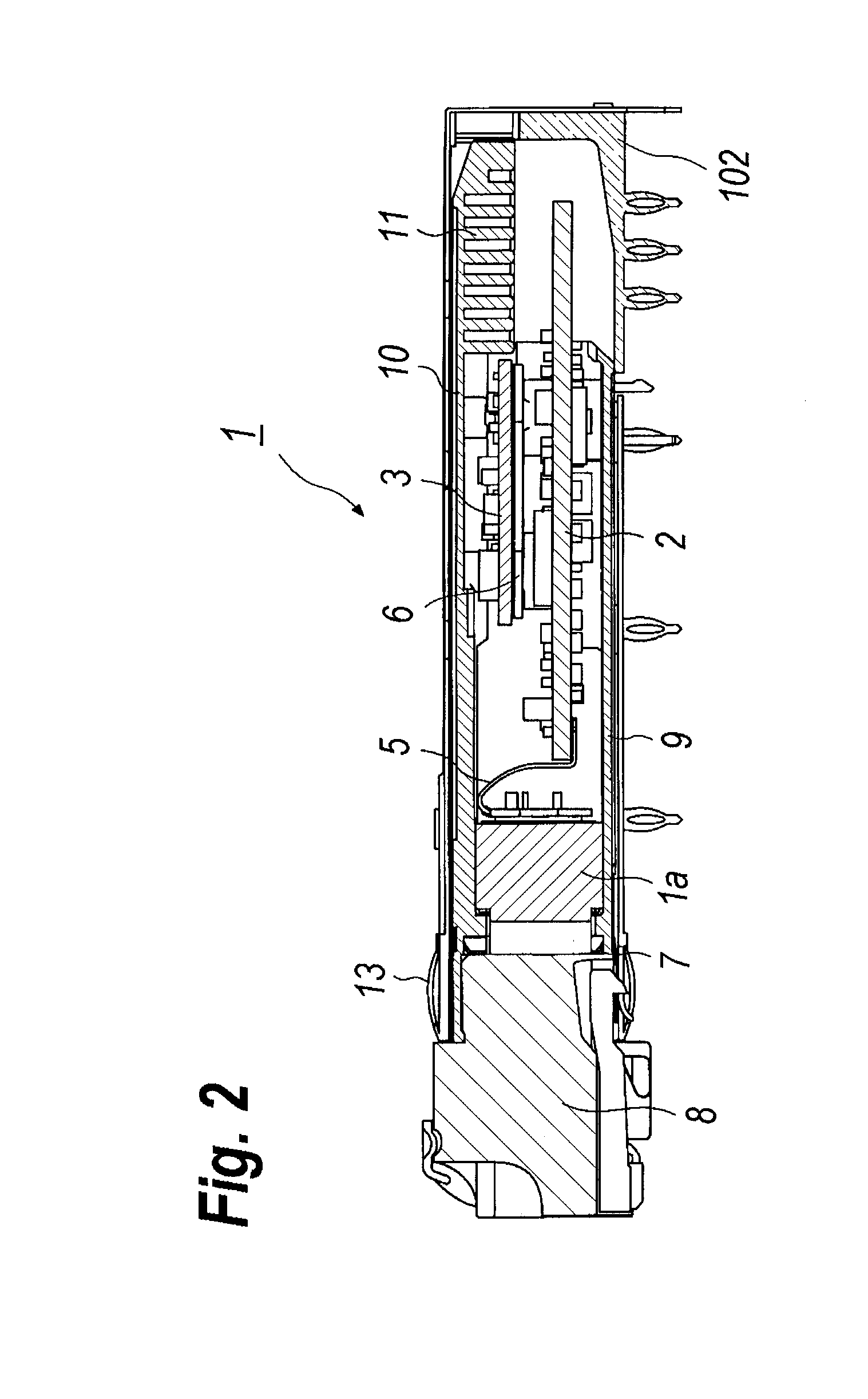

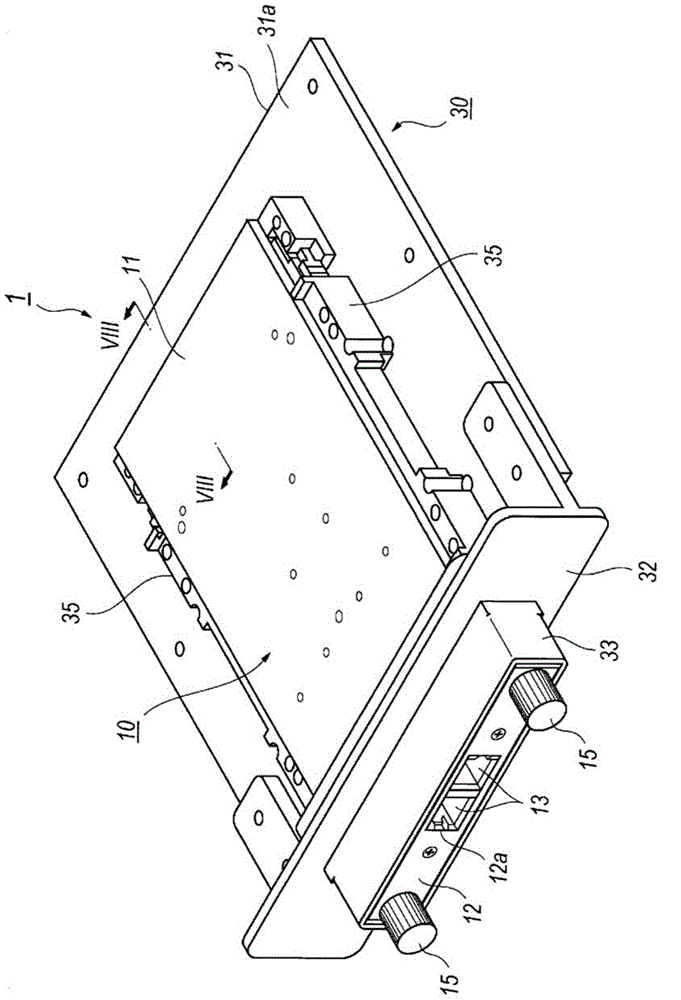

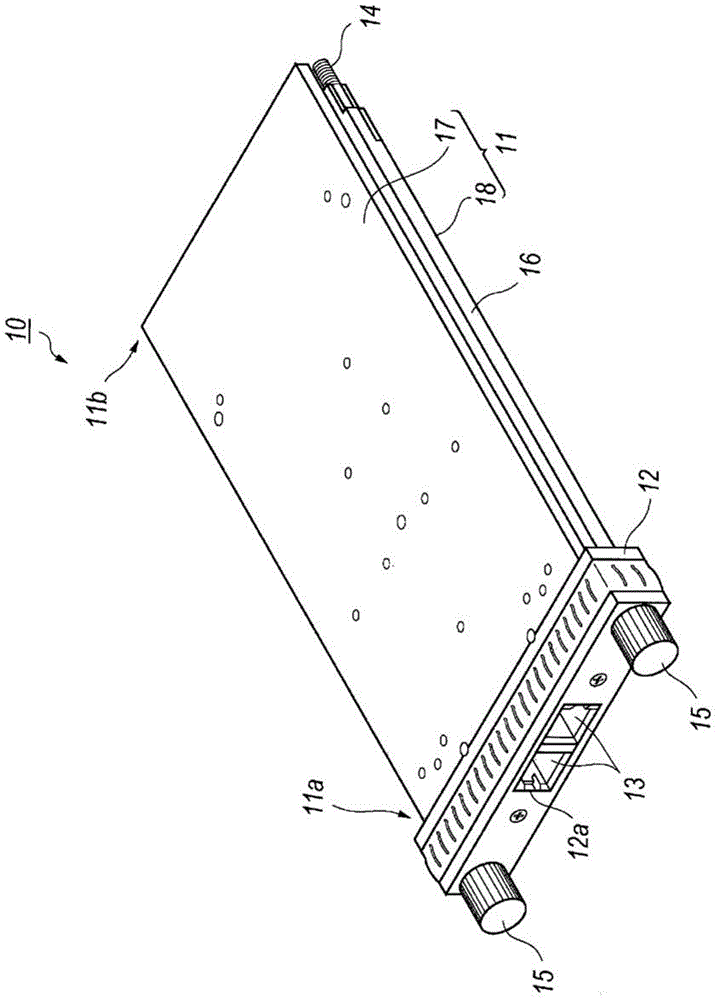

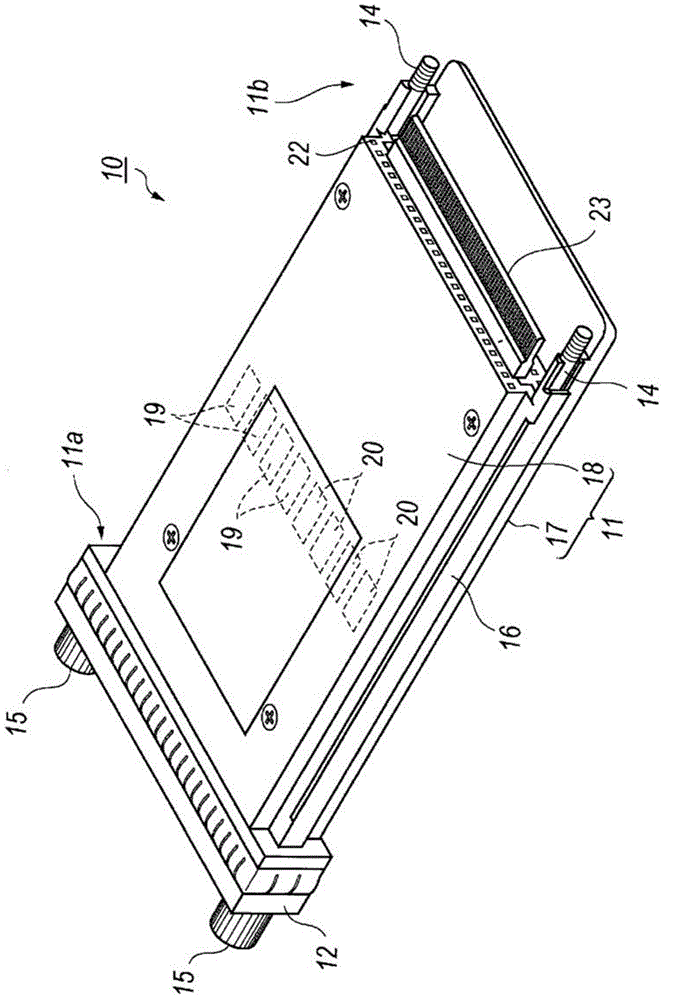

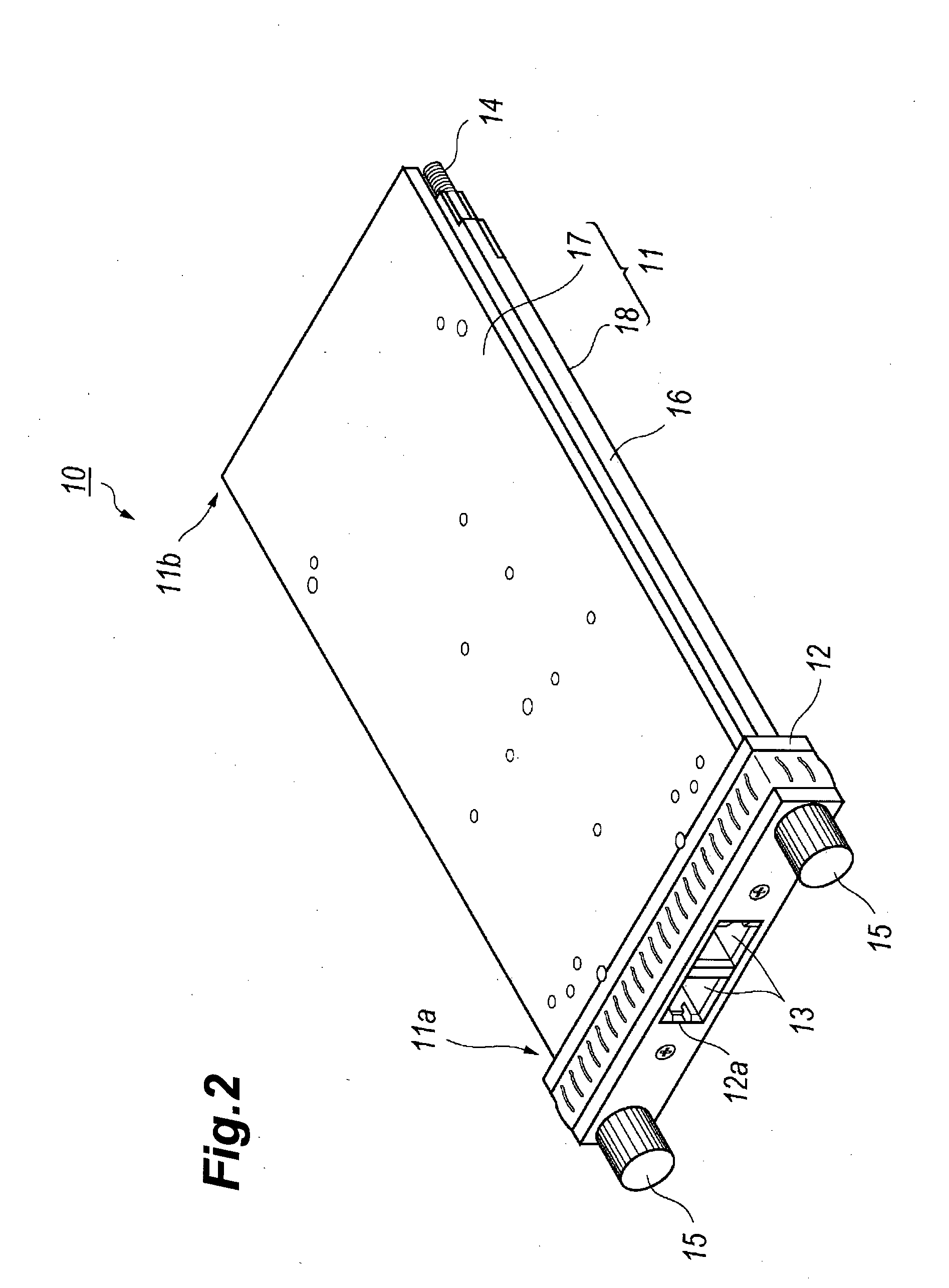

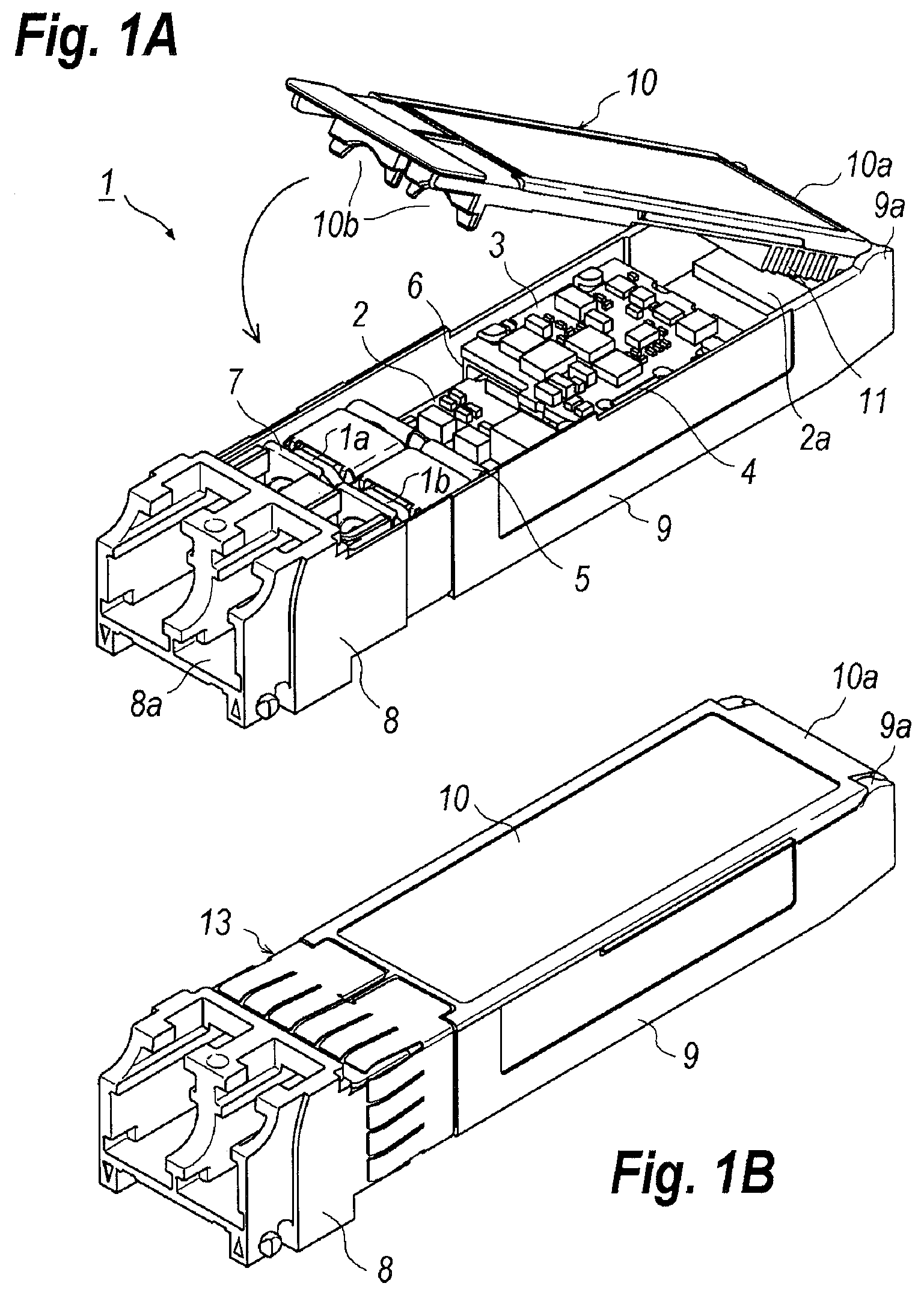

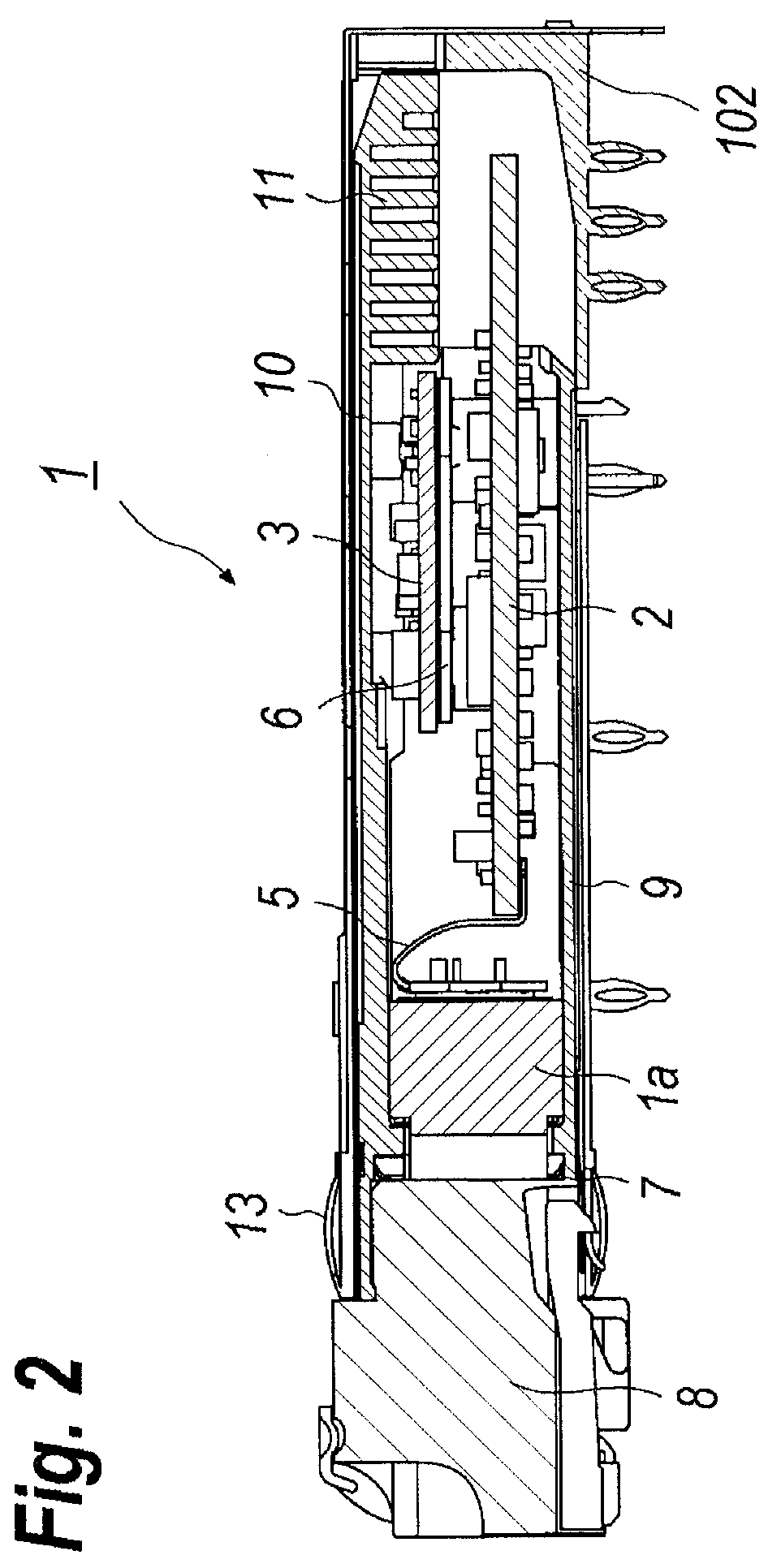

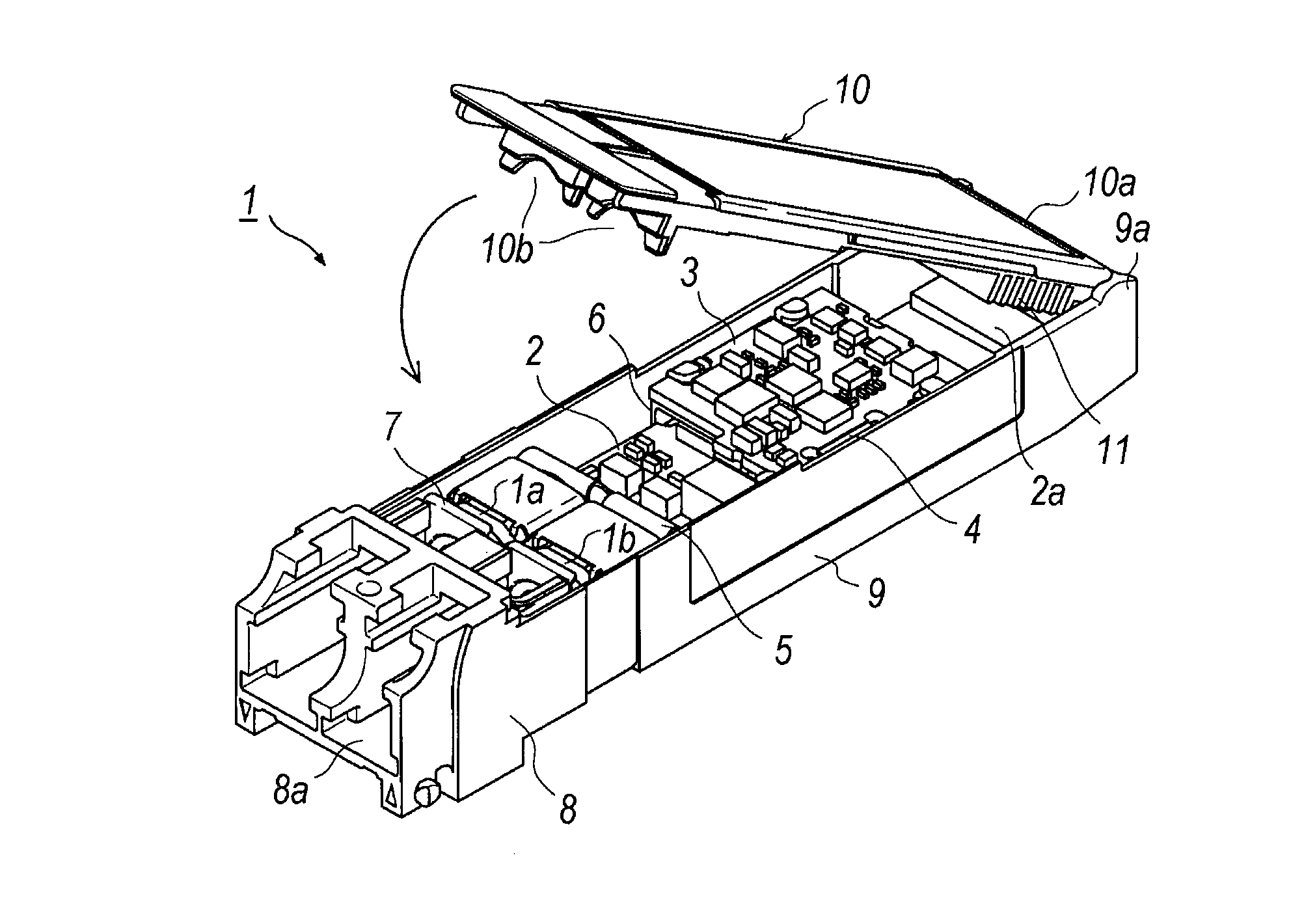

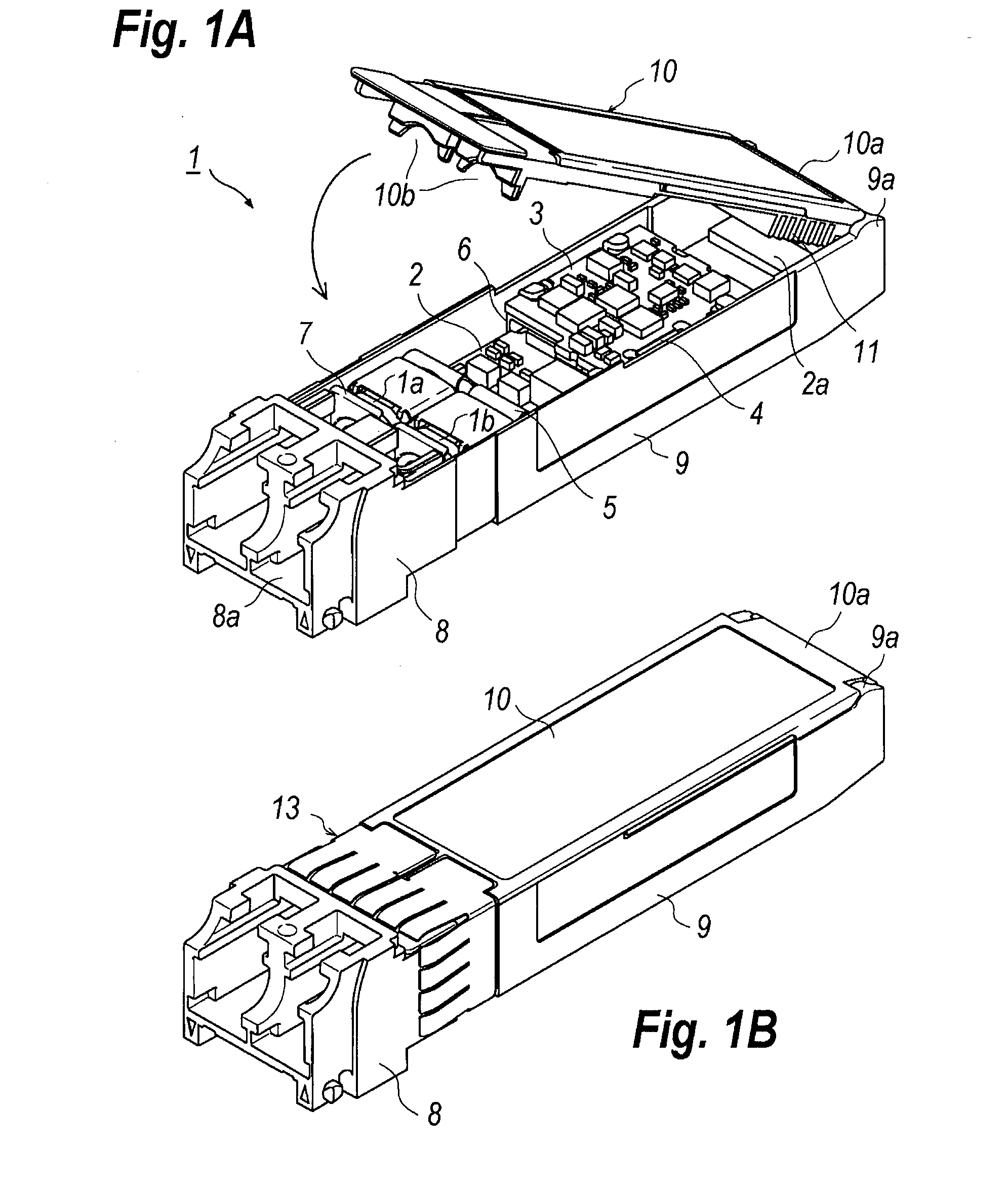

Optical transceiver having enhanced EMI tolerance

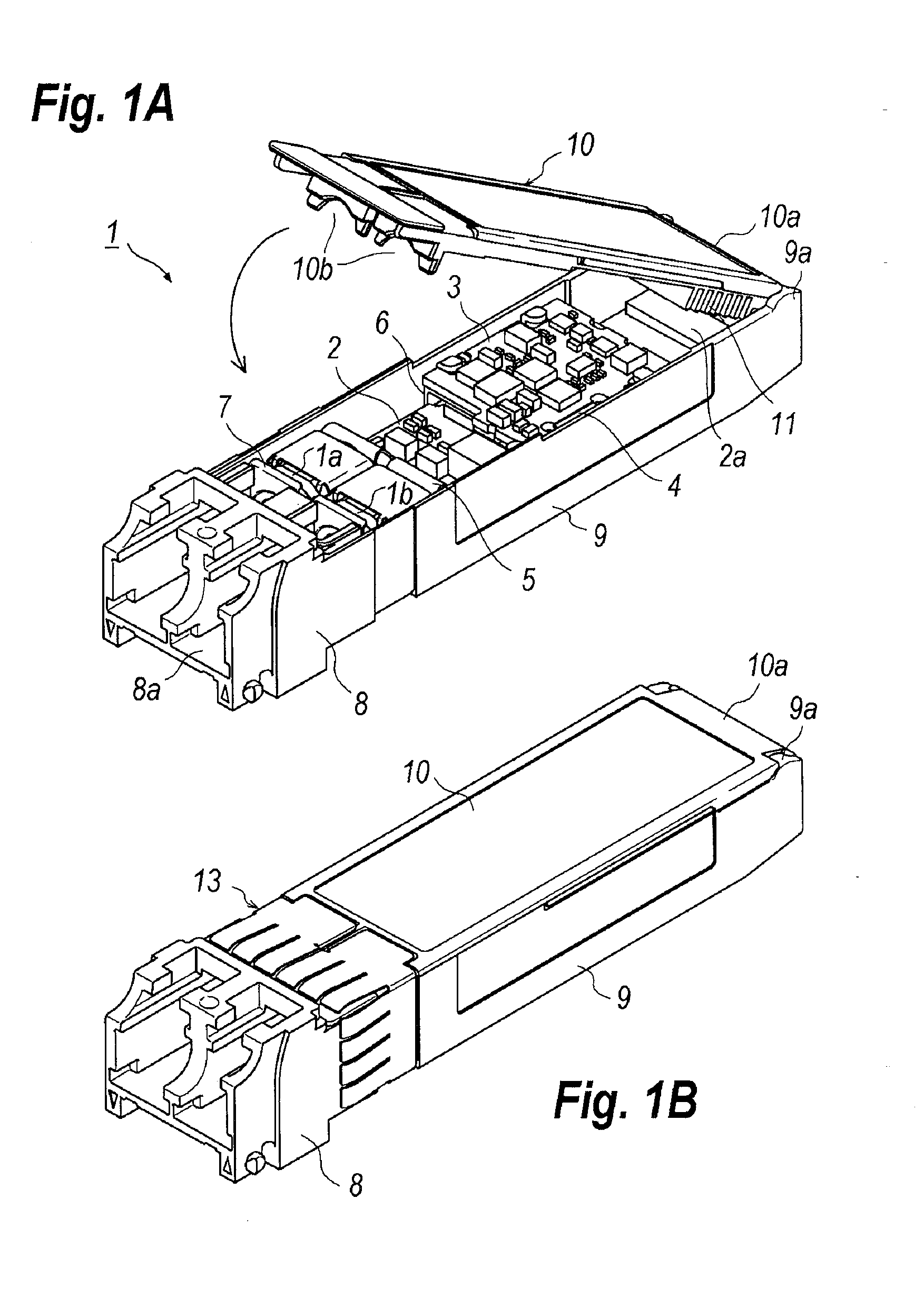

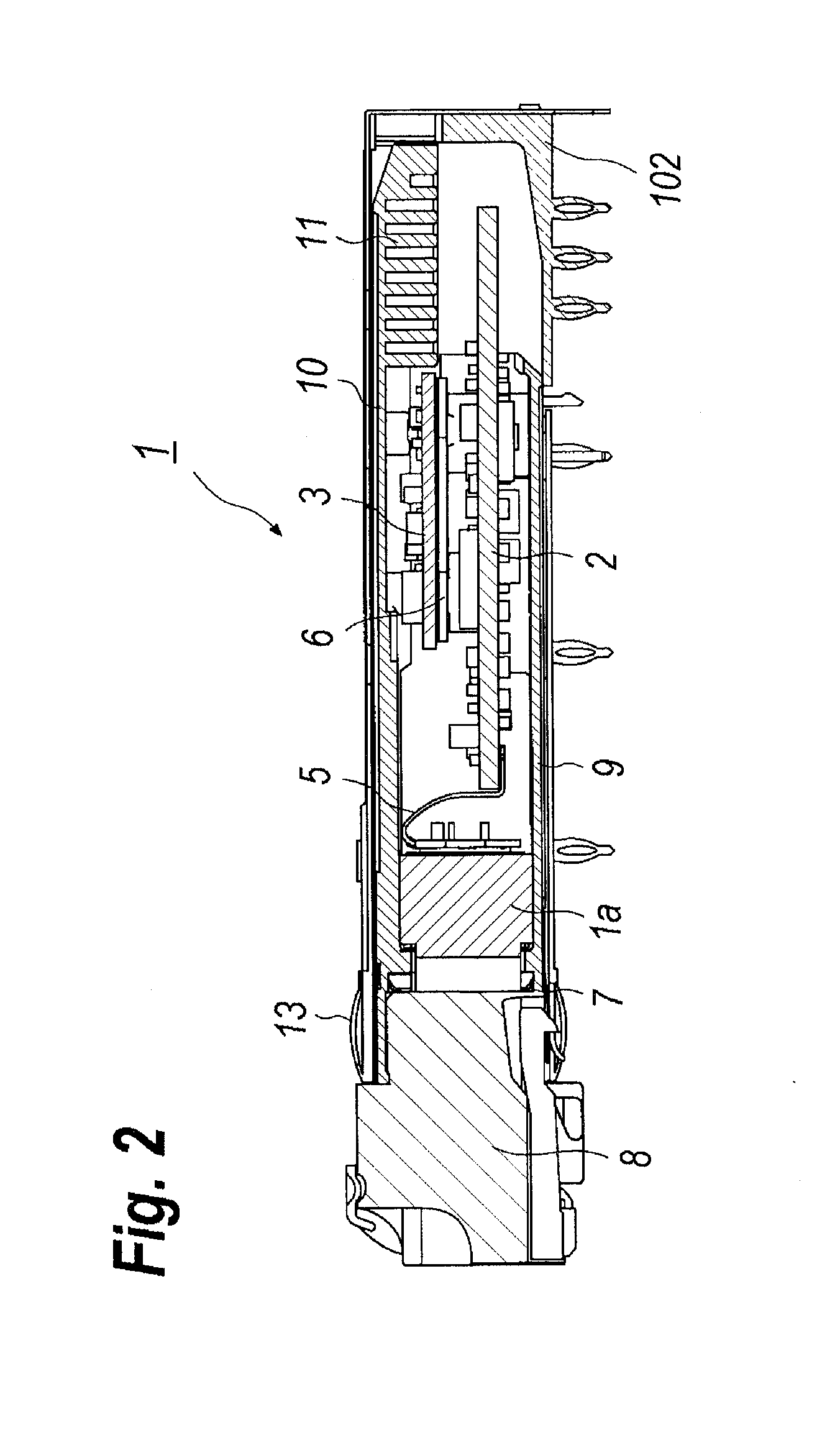

An optical transceiver that attenuates the EMI radiation leaked therefrom is disclosed. The optical transceiver includes a top cover and the bottom base to form a cavity into which a TOSA, a ROSA, and a circuit are set. At least one of the top cover and the bottom base provides a combed structure in a rear portion of the optical transceiver, where the combed structure has a plurality of T-shaped fins to attenuate the EMI radiation.

Owner:SUMITOMO ELECTRIC IND LTD

Optical transceiver having enhanced EMI tolerance

ActiveUS20120315051A1Magnetic/electric field screeningElectromagnetic transmissionTransceiverEngineering

An optical transceiver that reduces the EMI radiation leaked therefrom is disclosed. The optical transceiver includes a top cover and the bottom base to form a cavity into which a TOSA, a ROSA, and a circuit are set. The top cover provides a combed structure in a rear portion thereof, where the combed structure has a plurality of fins with a distance preferably less that quarter wavelength λ / 4 of the noise wavelength to be reduced. The combed structure operates as a short stub for the electromagnetic wave traveling longitudinally in the cavity.

Owner:SUMITOMO ELECTRIC IND LTD

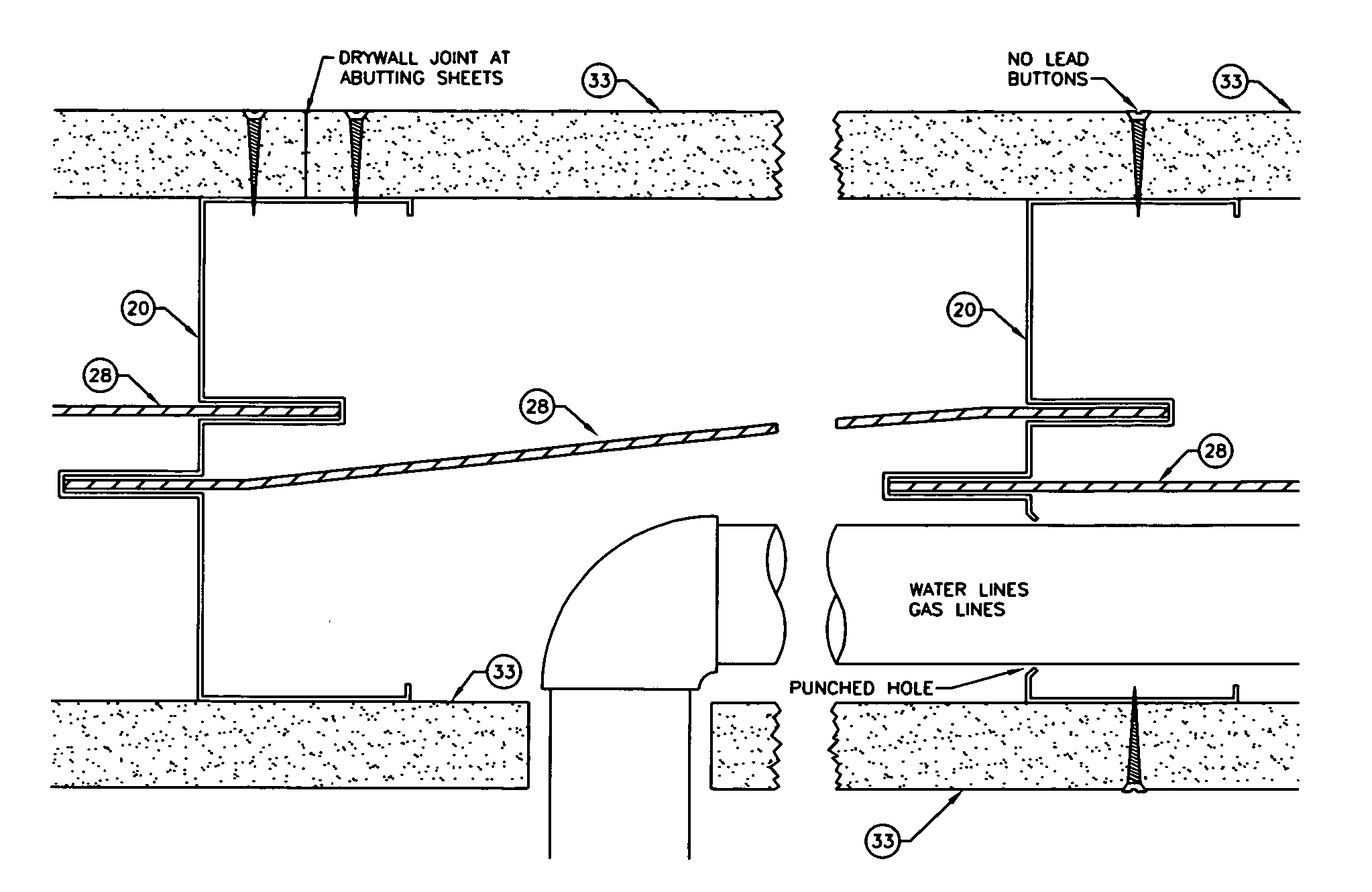

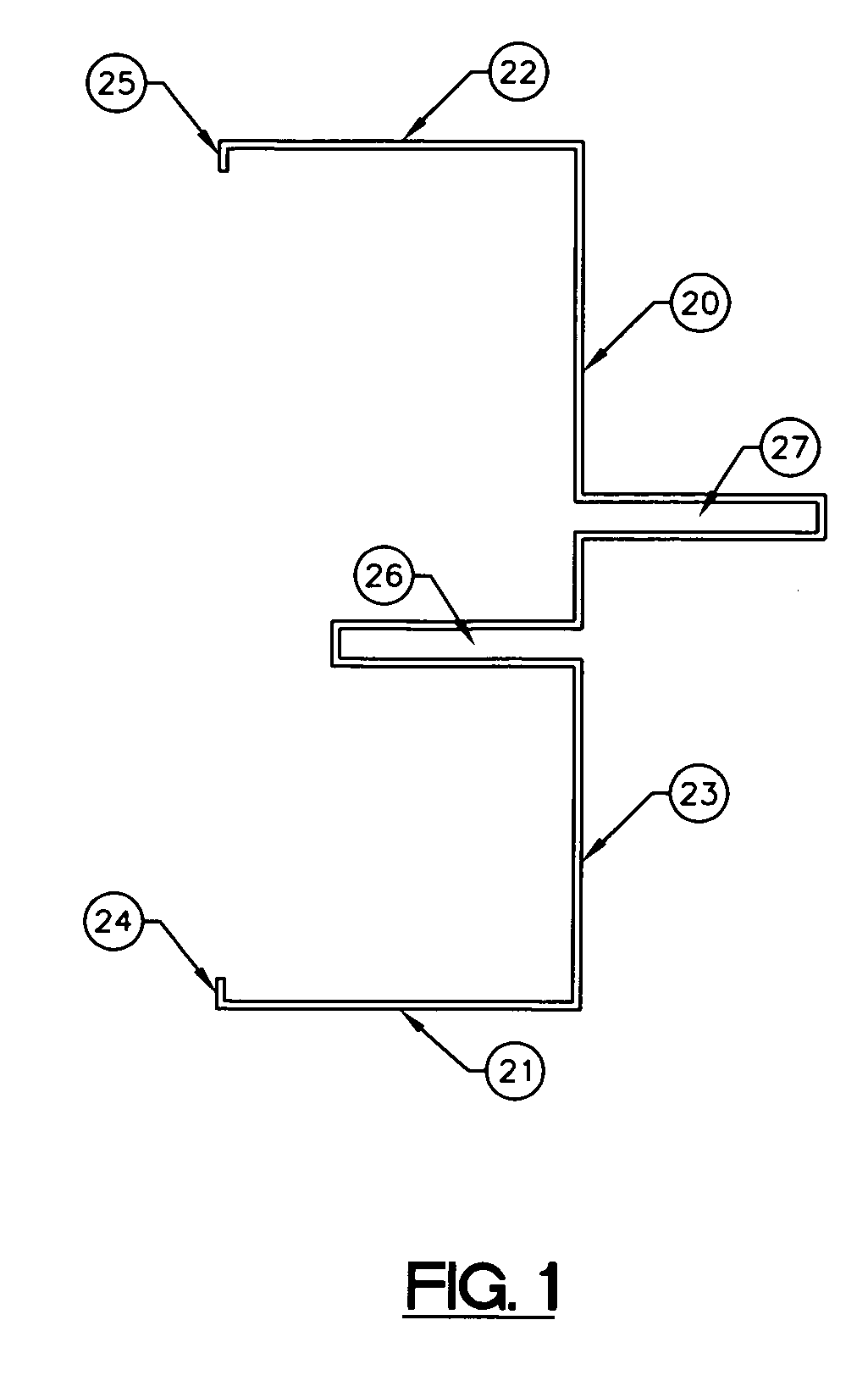

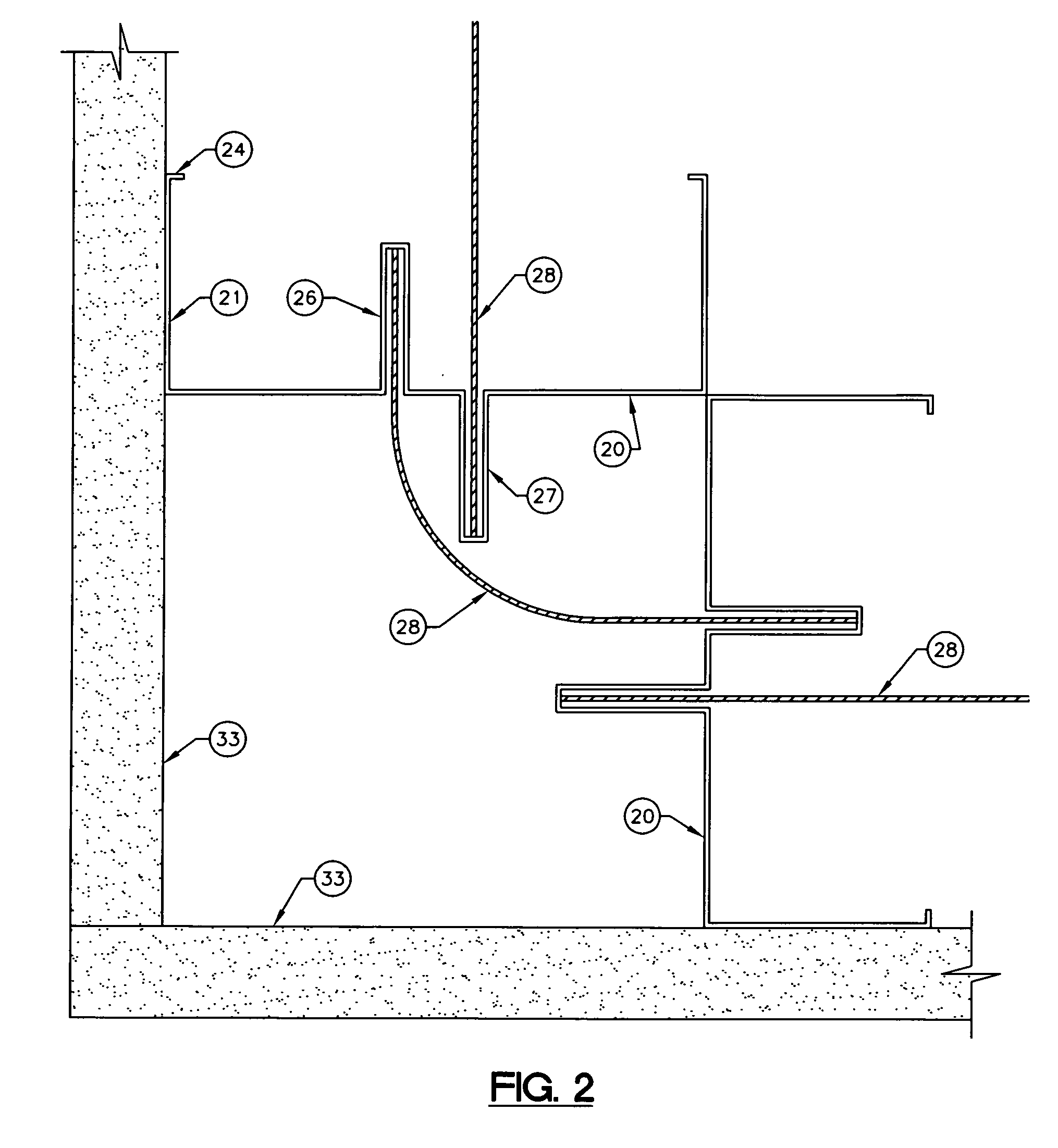

Lead sheet suspension stud

InactiveUS20100212243A1Eliminate needReduce potential for back injuryWallsGirdersLead sheetEngineering

Owner:LESOINE DAVID ALLEN

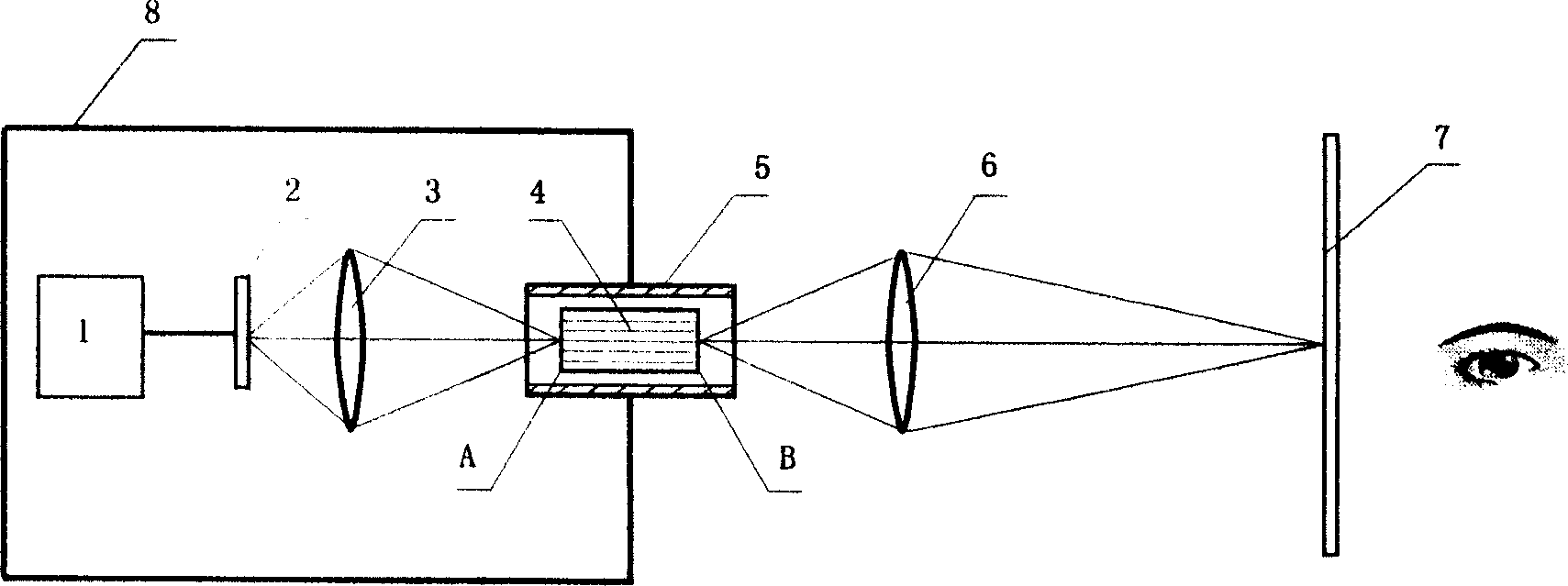

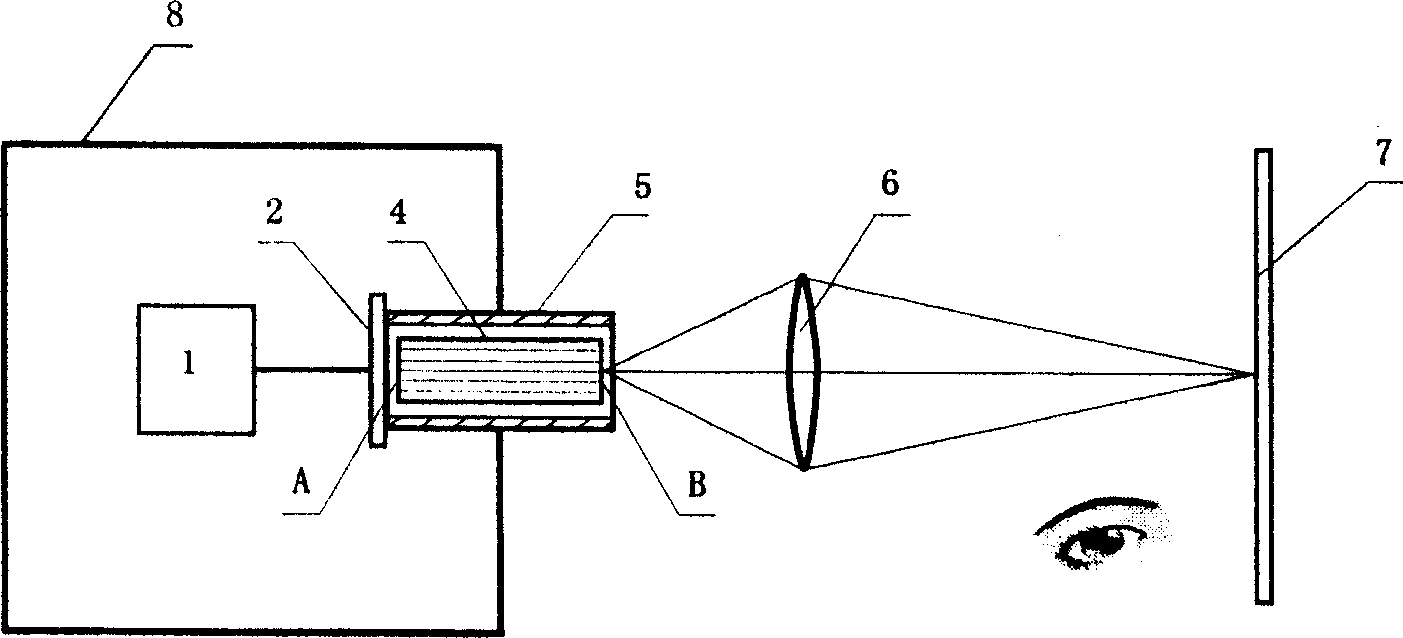

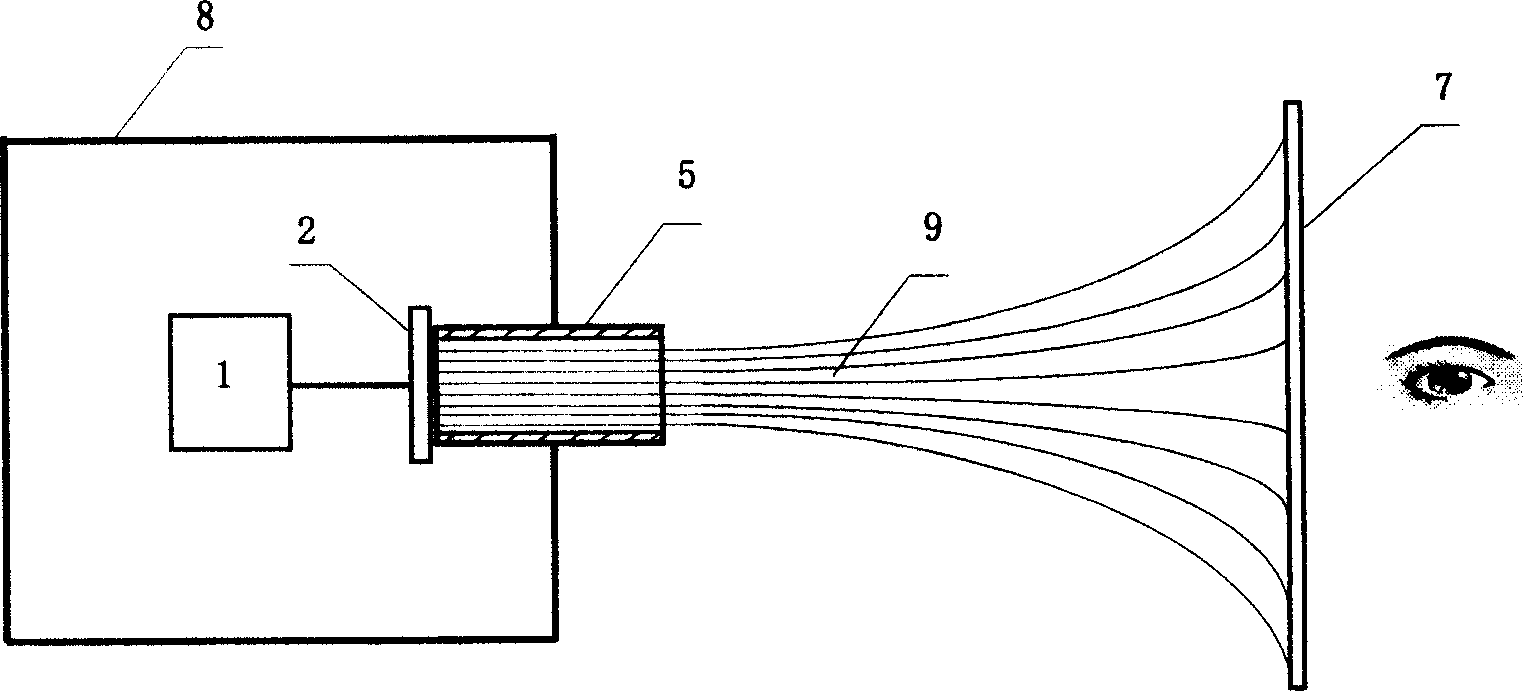

Video imaging device with low radiation

InactiveCN1908710ASolving Electromagnetic CouplingSolve the problem of electromagnetic radiation leakage of screen informationMagnetic/electric field screeningDigital data processing detailsElectromagnetic radiationElectromagnetic shielding

The disclosed low-radiation video imaging device comprises: an image source, a display chip, an imaging fiber, an EM-wave closure tube, and a screen, wherein it can convert video signal in shield body into optical signal to output outside through the imaging fiber arranged on a through-hole on the body, and recovers the image on outside screen by orthogonal or back projection. Unlike to traditional product, this invention can overcome the EM radiation efficiently, and can also be used for computer to prevent damage to people.

Owner:杨子刚 +1

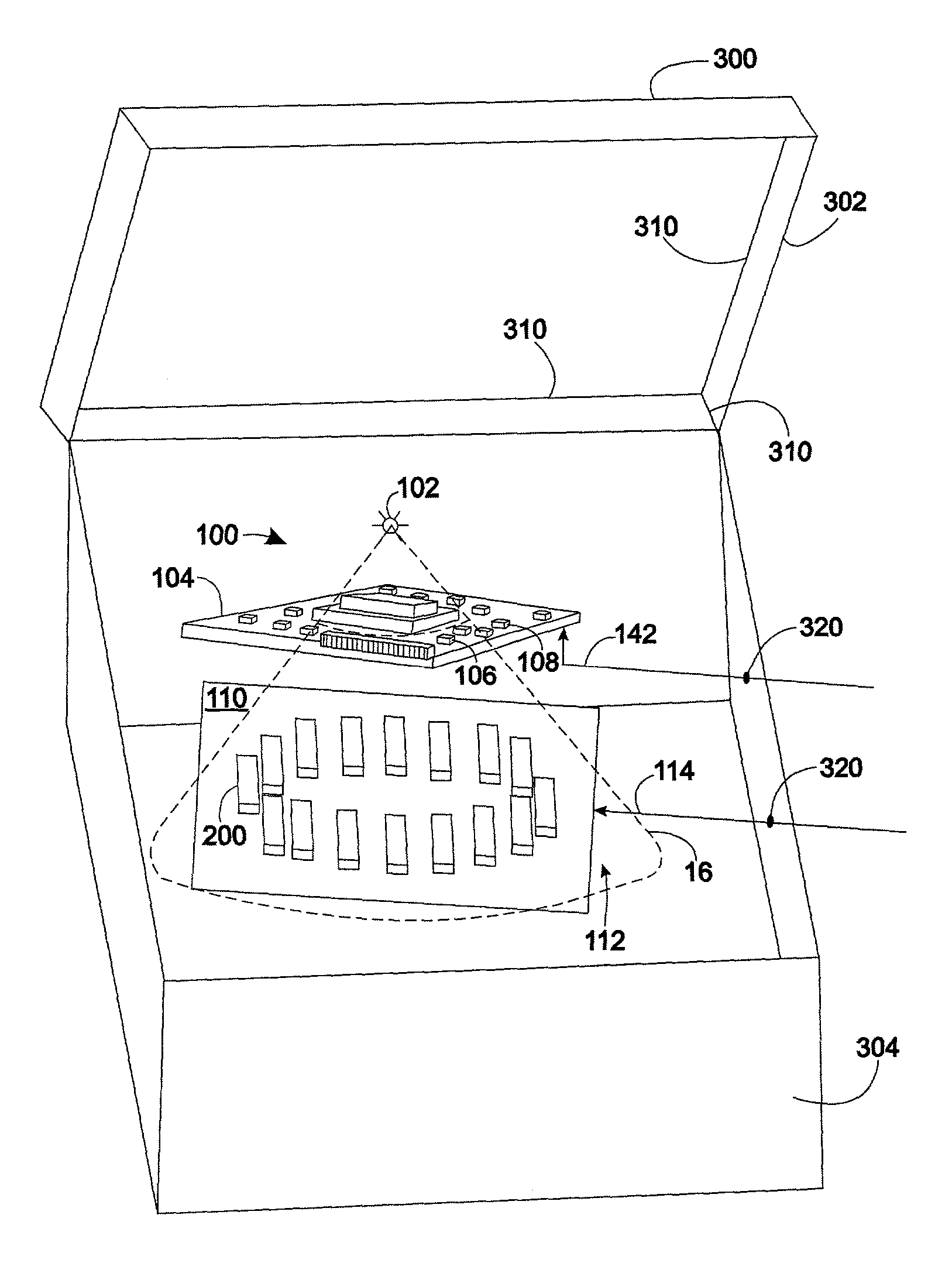

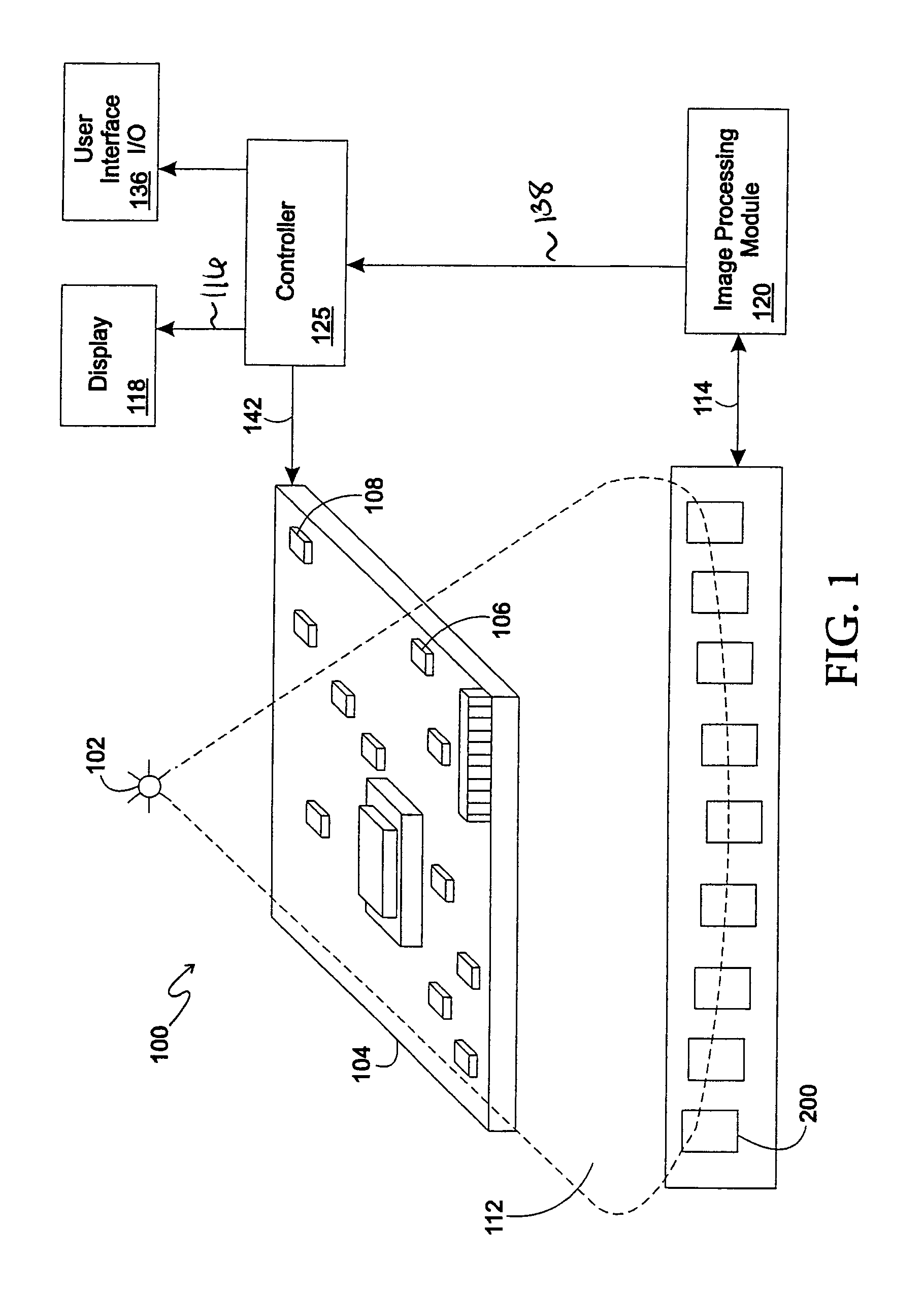

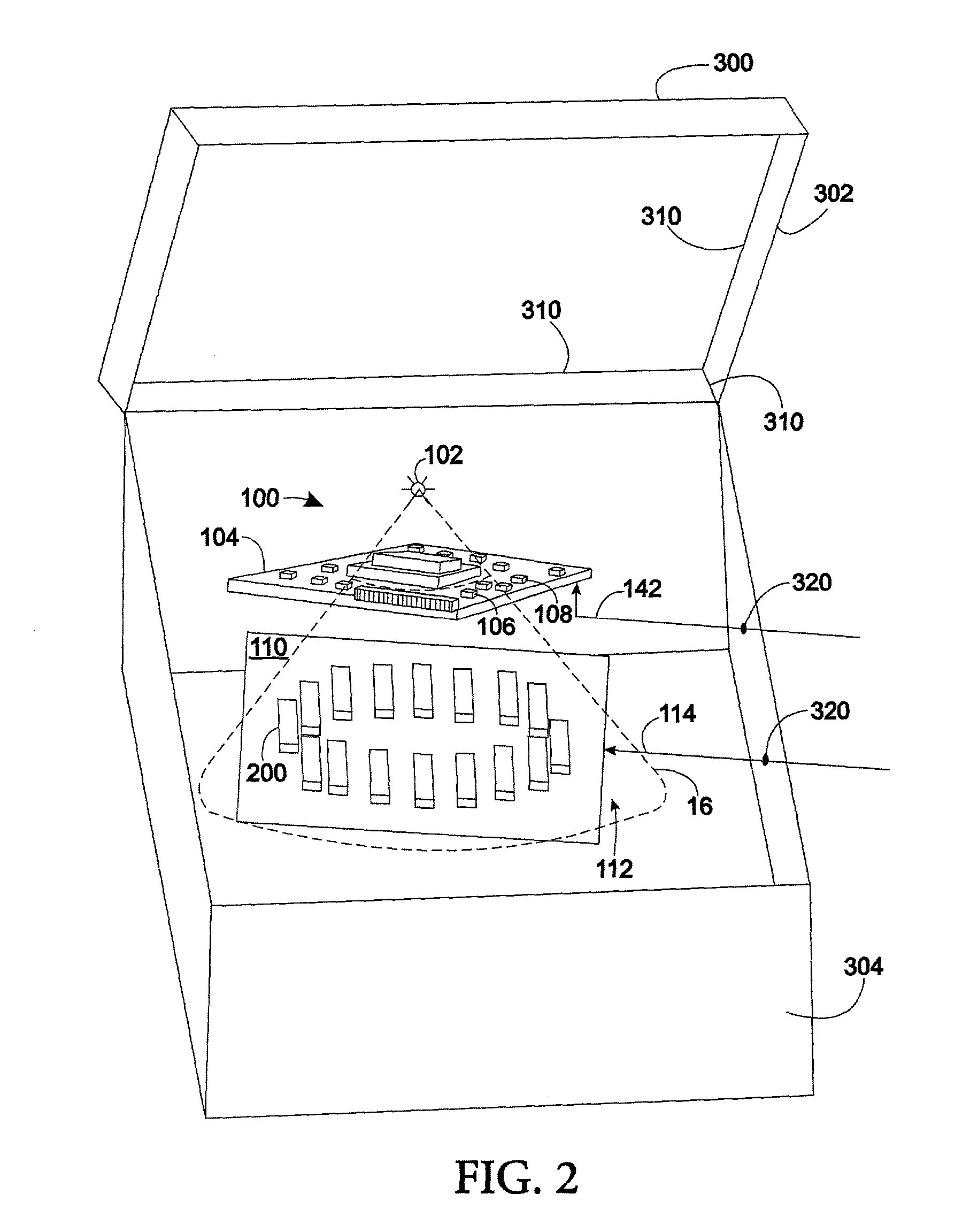

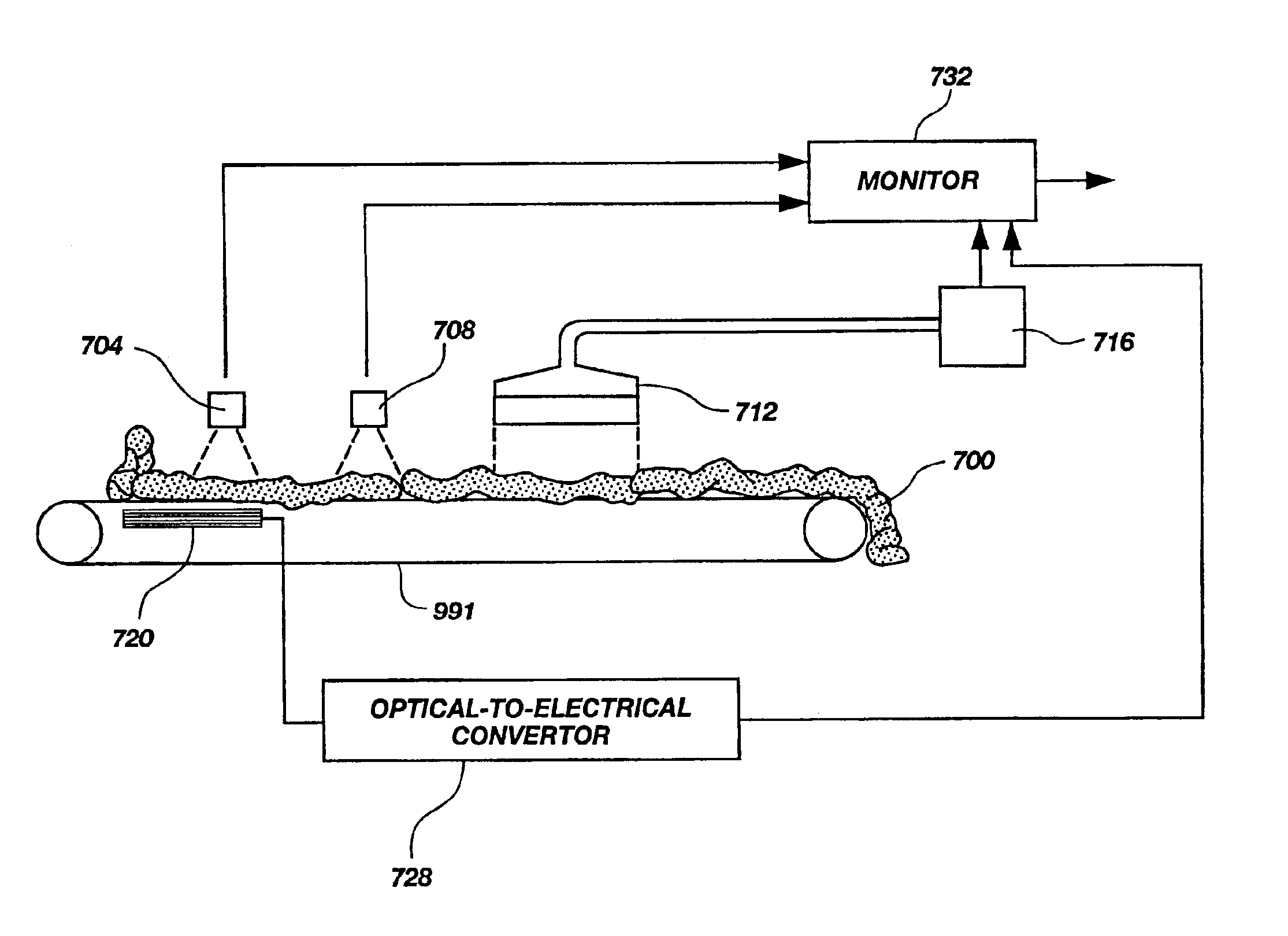

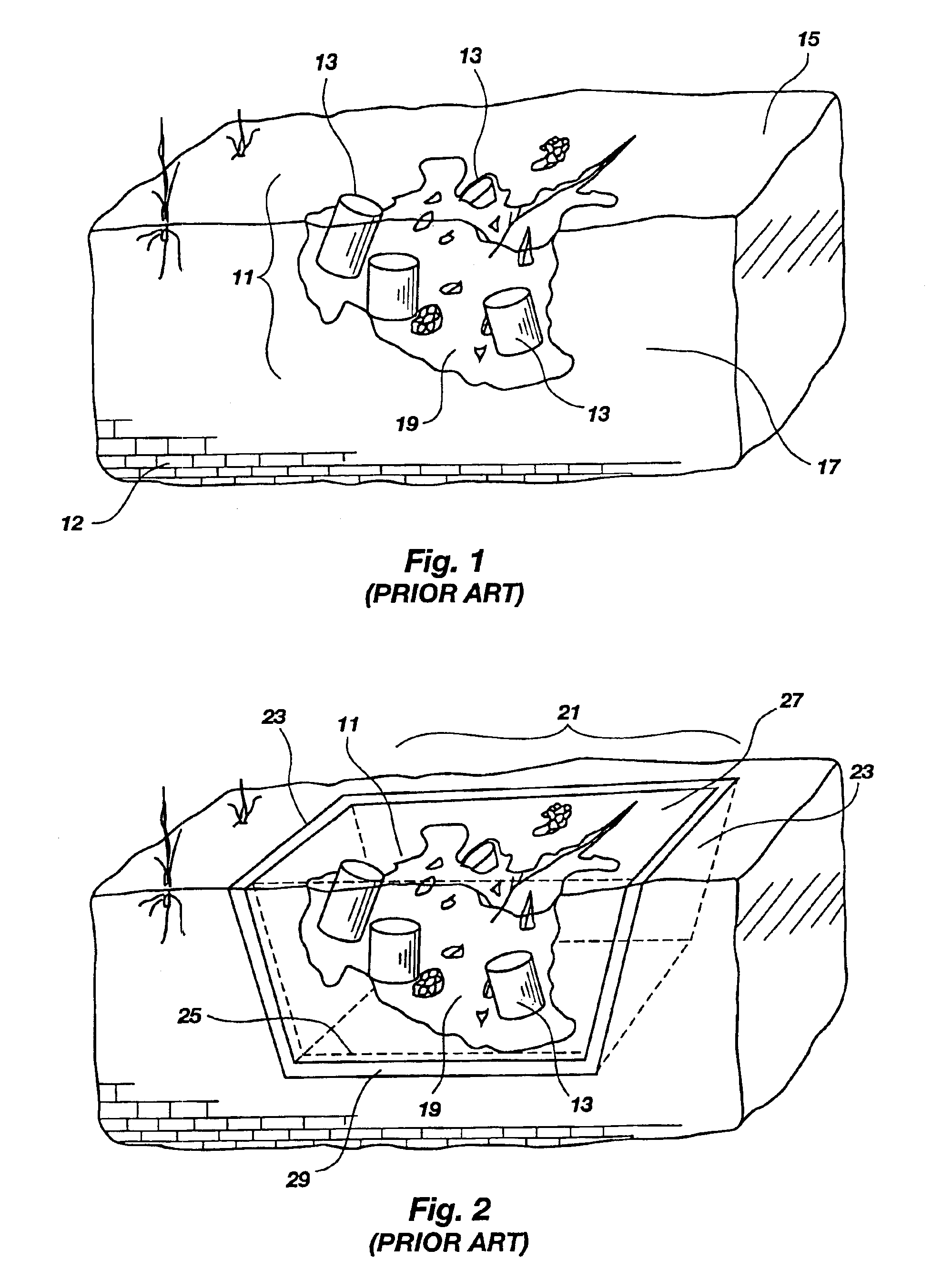

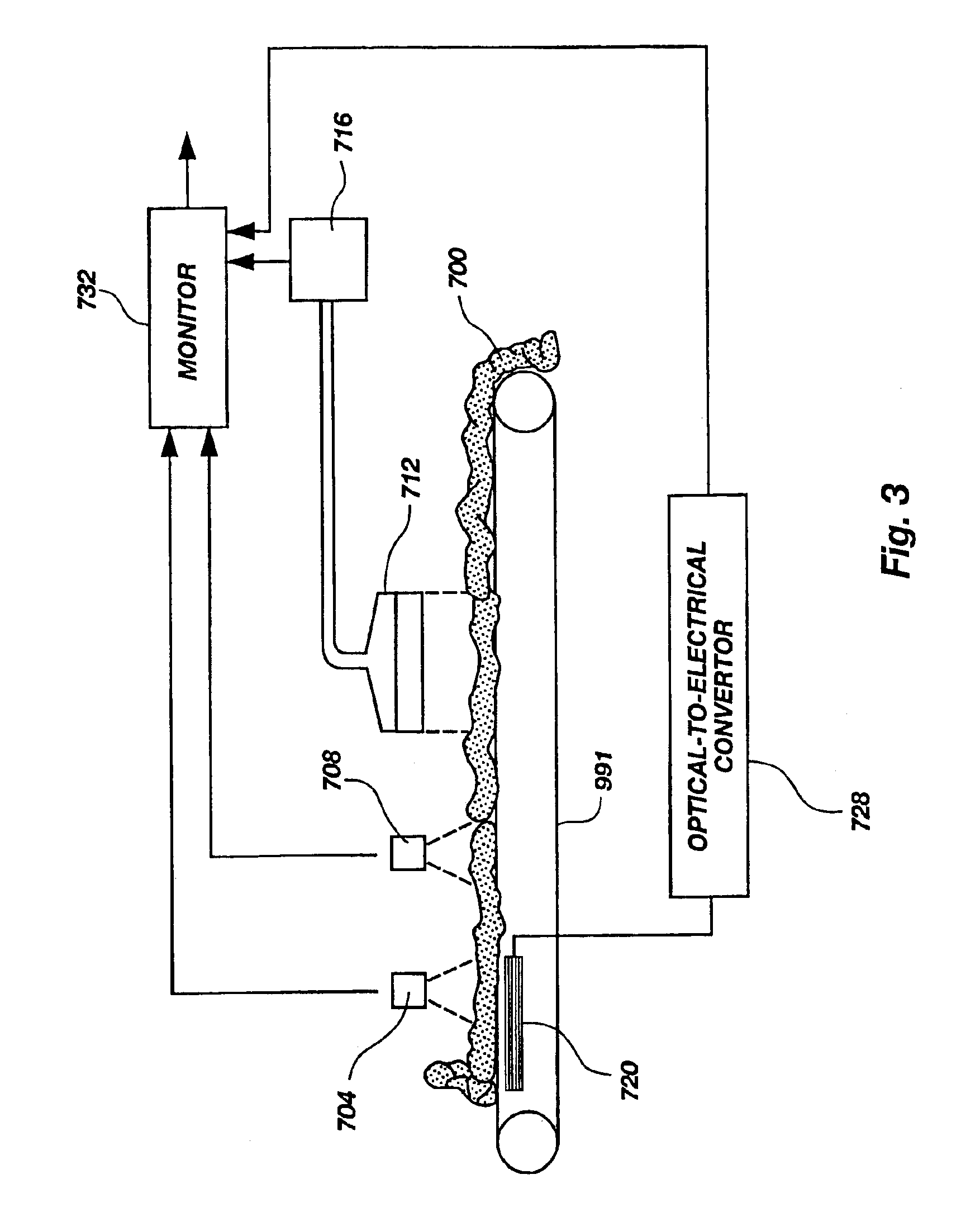

Sensor system for buried waste containment sites

A sensor system for a buried waste containment site having a bottom wall barrier and / or sidewall barriers, for containing hazardous waste. The sensor system includes one or more sensor devices disposed in one or more of the barriers for detecting a physical parameter either of the barrier itself or of the physical condition of the surrounding soils and buried waste, and for producing a signal representing the physical parameter detected. Also included is a signal processor for receiving signals produced by the sensor device and for developing information identifying the physical parameter detected, either for sounding an alarm, displaying a graphic representation of a physical parameter detected on a viewing screen and / or a hard copy printout. The sensor devices may be deployed in or adjacent the barriers at the same time the barriers are deployed and may be adapted to detect strain or cracking in the barriers, leakage of radiation through the barriers, the presence and leaking through the barriers of volatile organic compounds, or similar physical conditions.

Owner:BATTELLE ENERGY ALLIANCE LLC

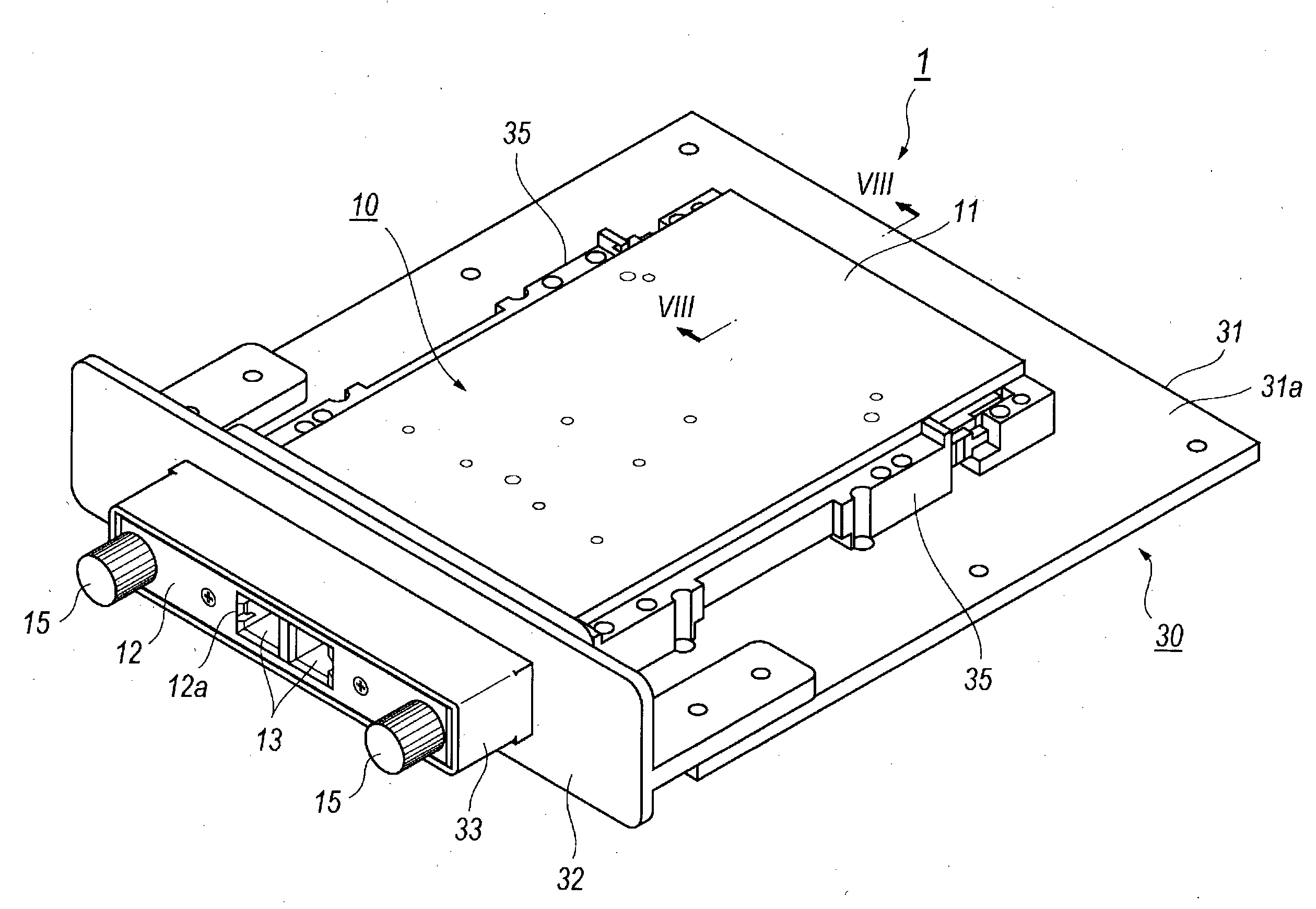

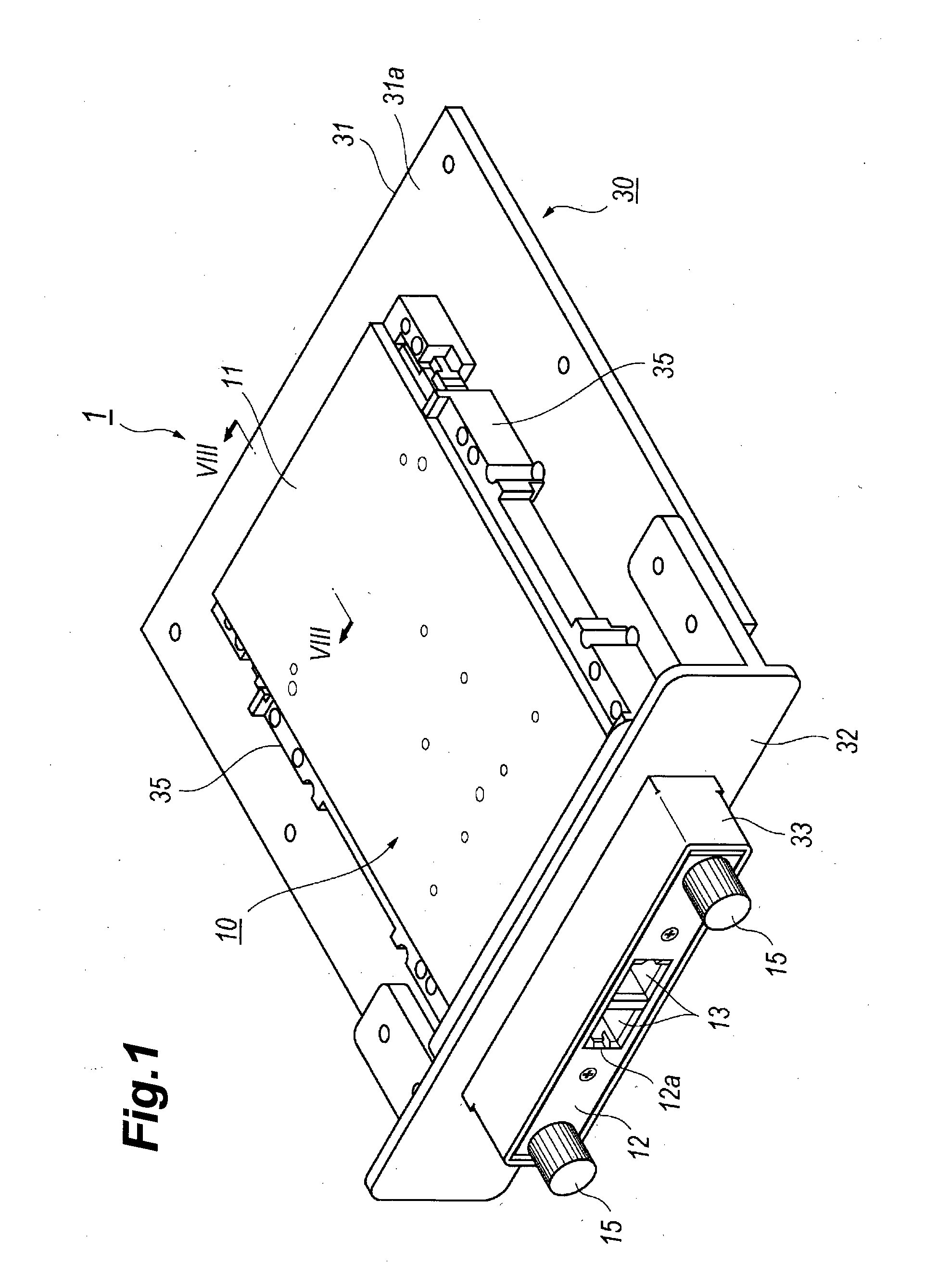

Pluggable system and optical transceiver applicable to pluggable system

InactiveCN103563187APrevent leakageCoupling light guidesDistortion/dispersion eliminationTransceiverEngineering

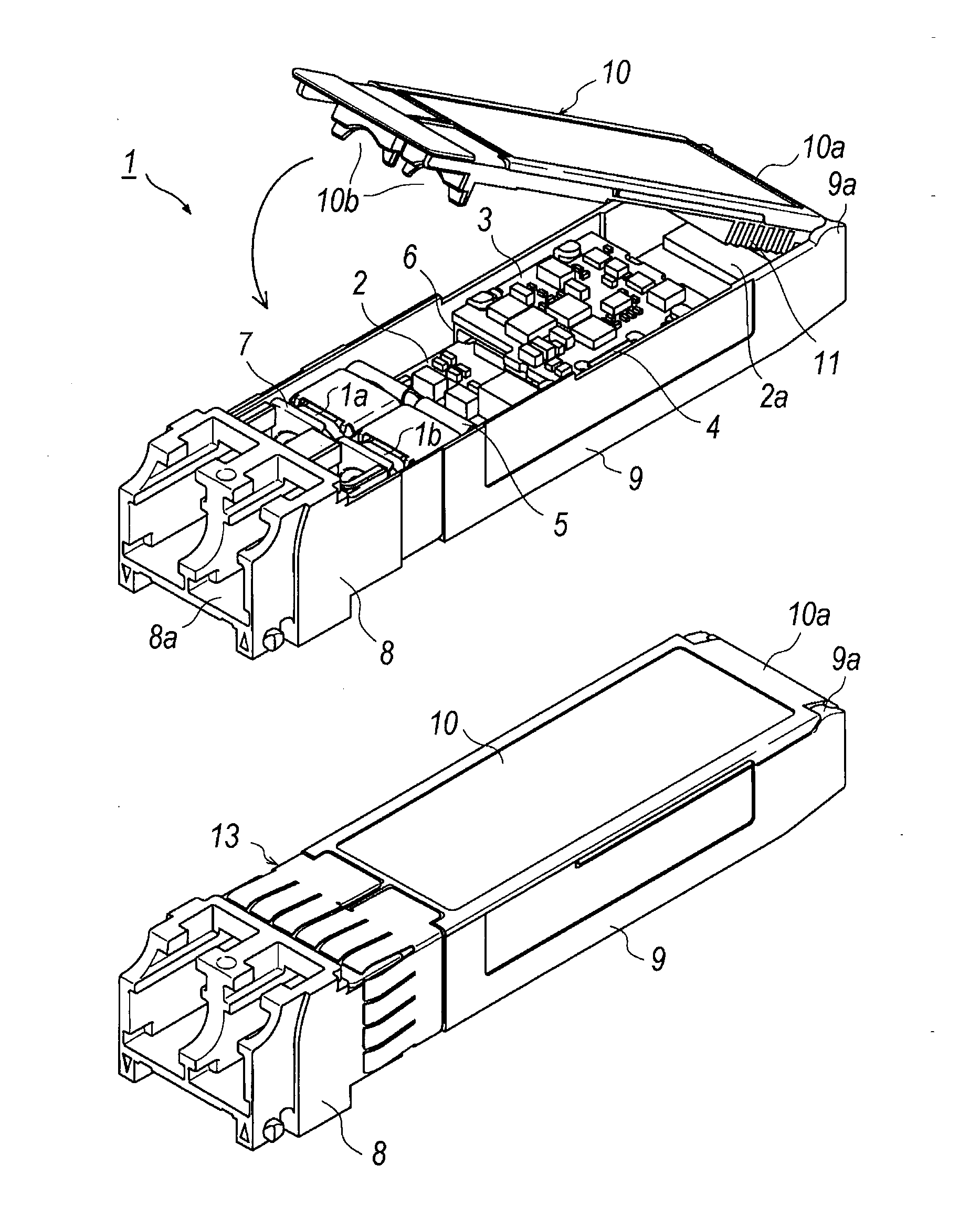

An optical transceiver and a pluggable system to enhance the reliability of the communication between the optical transceiver and the host system are disclosed. The rear of the housing of the transceiver provides a periodic structure, a plurality of hollows or a plurality of projections, arranged along the gasket provided in the host connector. Only portions of the periodic structure come in contact with the gasket, and the repulsive force caused by the gasket is consequently weakened to enhance the reliability of the mating of the plug in the optical transceiver with the host connector. The width of the hollows, or the pitch of the projections is set to be shorter than a quarter wavelength of a signal transmitted between the transceiver and the host system to reduce the EMI radiation leaking from the end of the transceiver.

Owner:SUMITOMO ELECTRIC IND LTD

Pluggable system and optical transceiver applicable to pluggable system

InactiveUS20140087577A1Prevent leakageCouplings bases/casesDistortion/dispersion eliminationTransceiverLength wave

An optical transceiver and a pluggable system to enhance the reliability of the communication between the optical transceiver and the host system are disclosed. The rear of the housing of the transceiver provides a periodic structure, a plurality of hollows or a plurality of projections, arranged along the gasket provided in the host connector. Only portions of the periodic structure come in contact with the gasket, and the repulsive force caused by the gasket is consequently weakened to enhance the reliability of the mating of the plug in the optical transceiver with the host connector. The width of the hollows, or the pitch of the projections is set to be shorter than a quarter wavelength of a signal transmitted between the transceiver and the host system to reduce the EMI radiation leaking from the end of the transceiver.

Owner:SUMITOMO ELECTRIC IND LTD

Optical fiber, optical fiber cable, and radiation detecting system using such

InactiveUS20040071433A1Glass optical fibreOptical fibre with multilayer core/claddingPhotoelectric conversionScintillator

The present invention provides an optical fiber, an optical fiber cable and a radiation detecting system at a low cost. Further, the radiation detecting system is provided which can adequately monitor the radiation leak without delay. The optical fiber cable comprises: an optical fiber including; a core 12 having lightwave guide property and extending along one direction; a clad layer 14 covering over a peripheral surface of the core 12; and a scintillator material dispersed in the clad layer 14 and emitting light when radiation is applied, a radiation-shielding layer 24 covering substantially over a periphery of the optical fiber 10, and a gap 26 located in at least one part of the radiation-shielding layer 24. The radiation detecting system comprises an optical fiber cable 20 adapted to emit light at a region where radiation is applied and transmitting the emitted light, photoelectric conversion means 32 connected to at least one end of the optical fiber cable 20, and processing means 38 detecting when radiation is applied in accordance with an output signal of the photoelectric conversion means 32.

Owner:WIRED JAPAN

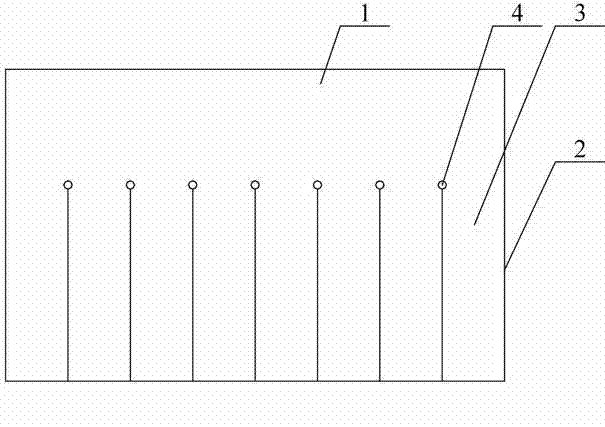

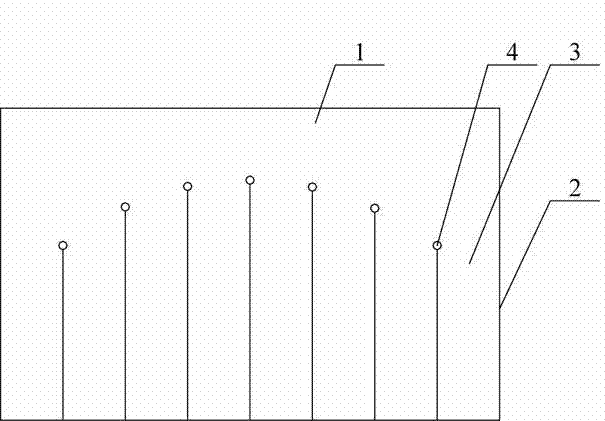

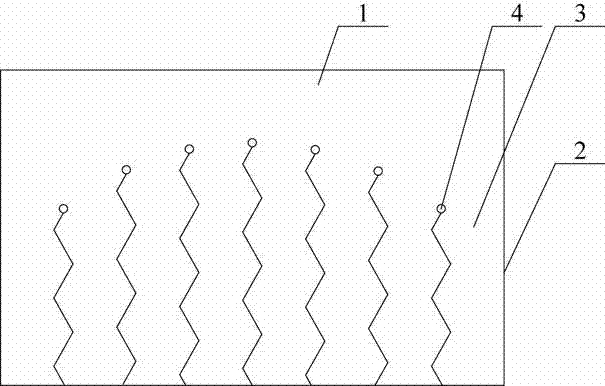

Integrated radiation shielding lead curtain and manufacturing method thereof

The invention discloses an integrated ray-shielding lead curtain and a manufacturing method thereof, and relates to the technical field of X-ray security inspection machines. Aiming at the problems of large amount of ray leakage and low production efficiency of the lead curtain assembled by lamination on the existing security inspection machine when it is set off. The integrated ray-shielding lead curtain is composed of a first part and a second part which are made into one. The first part is an integral structure, and the second part is composed of several sheet-shaped lead curtains arranged closely in sequence. The manufacturing method: a. uniformly cutting the lead-containing inner layer of the second part of the lead curtain to obtain a plurality of sheet-shaped lead curtains; b. sealing and packaging the lead-containing inner layer obtained through step a with a wrapping layer. The invention is especially suitable for the radiation shielding lead curtain of the security inspection machine and its manufacture.

Owner:SHANGHAI EASTIMAGE EQUIP

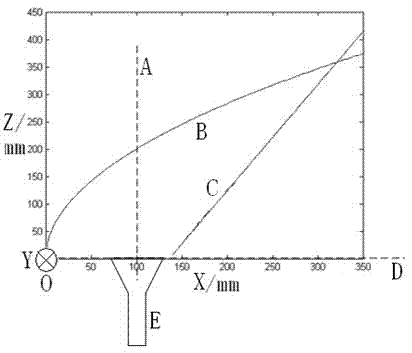

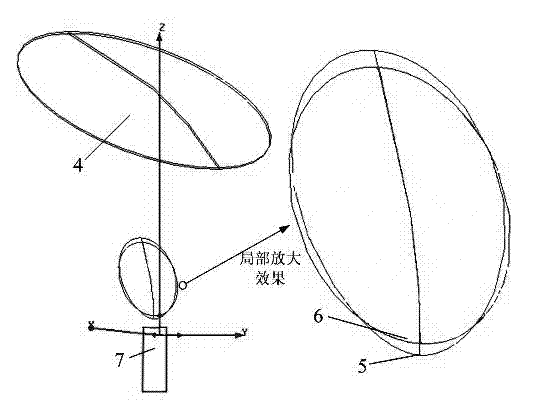

Shaping design method for cold air reflection mirror of microwave radiometer

ActiveCN103487859AEven energy coverageLow leak rateWave based measurement systemsMirrorsCold airEngineering

The invention provides a shaping design method for a cold air reflection mirror of a microwave radiometer, which is applied to a feed source opening face calibration type radiometer. The shaping design method comprises the following steps: S1: determining a parabolic equation of the cold air reflection mirror so as to obtain a paraboloid parent body of the cold air reflection mirror; S2: determining a biasing angle of the cold air reflection mirror; S3: calculating energy distribution of a feed source; and S4: calculating an outline line of the cold air reflection mirror to obtain a section line of the cold air reflection mirror according to the energy distribution of the feed source, wherein the section line is rotated for one circle around the central line of the feed source to form a cone and the outline line of the cold air reflection mirror is formed by a crossed part of the cone and the paraboloid parent body. According to the shaping design method for the cold air reflection mirror of the microwave radiometer provided by the invention, special shaping is carried on the cold air reflection mirror so that the radiation leaking rate of a main antenna is reduced and the calibration precision is improved under the precondition that the cold air reflection mirror does not generate physical interference influences on remote sensing and observation of the main antenna.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

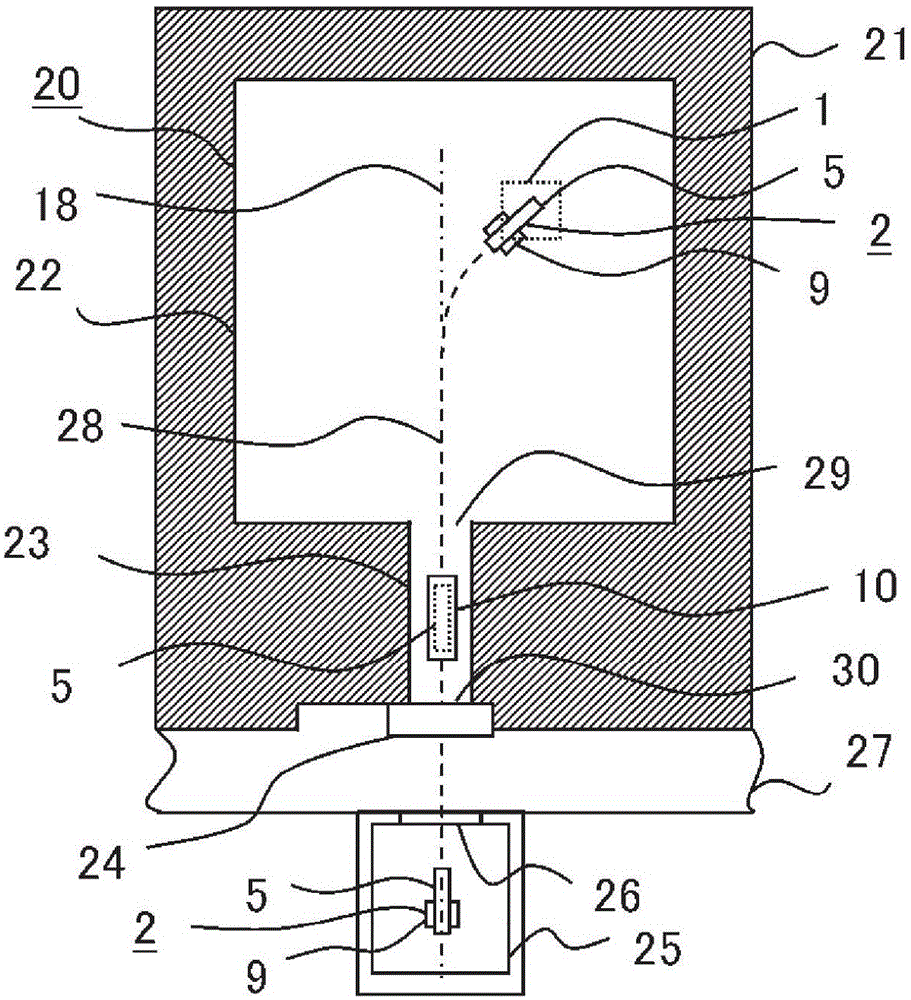

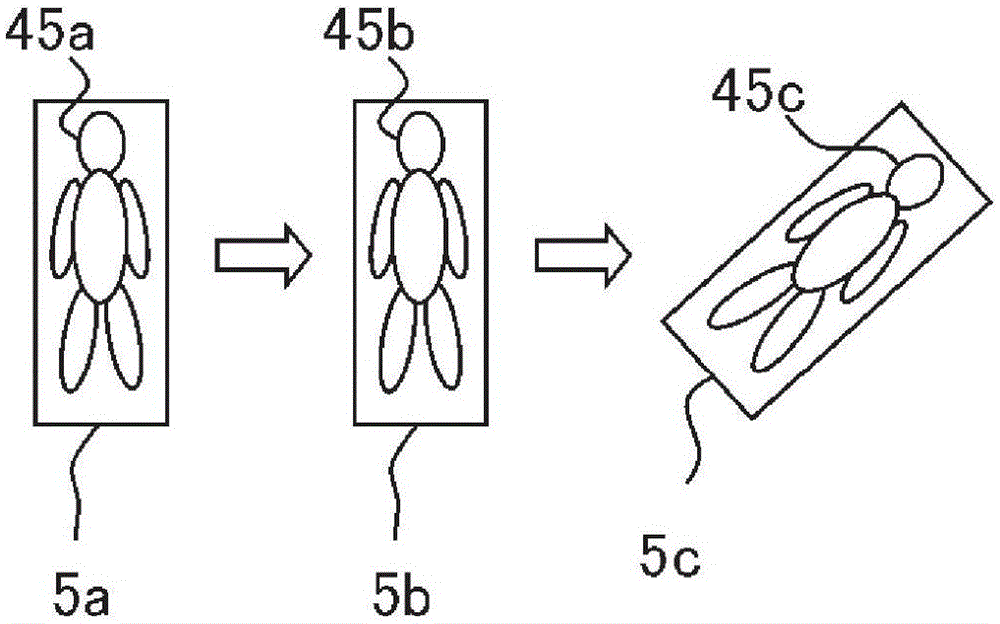

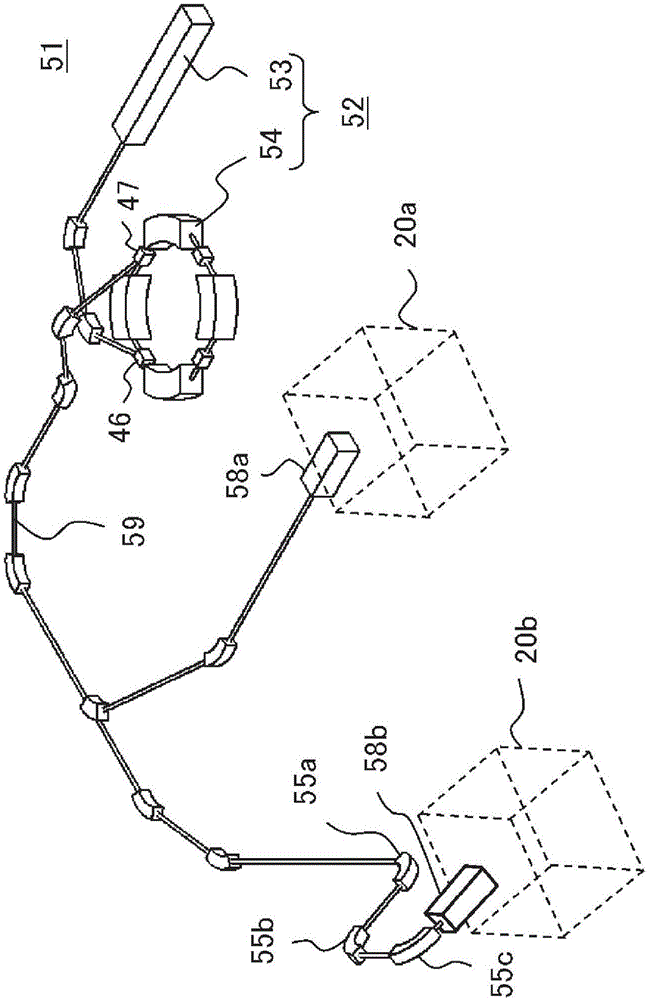

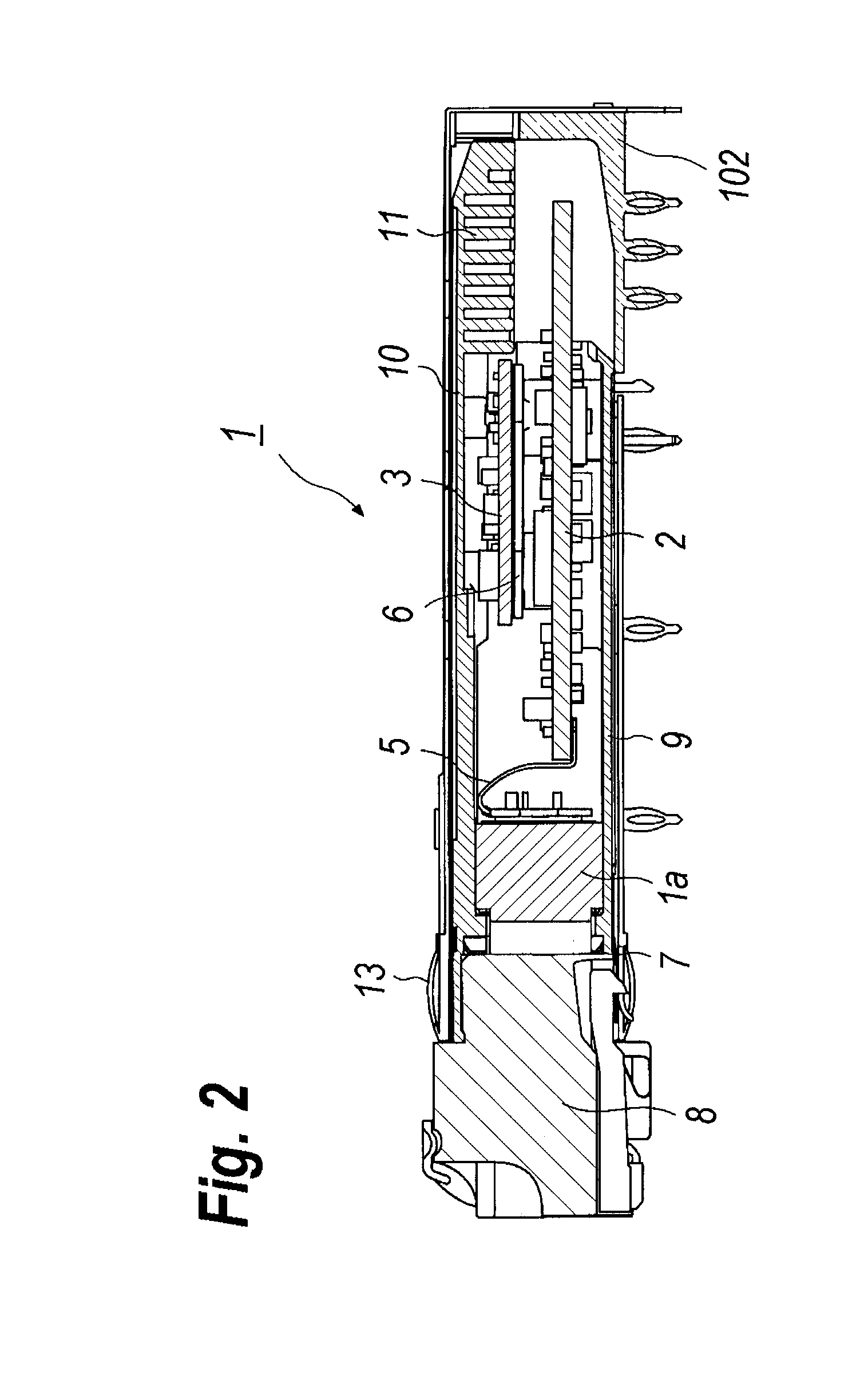

Particle beam projection chamber and particle beam treatment device

InactiveCN105102061AImprove utilization efficiencySave operating timeRadiation protectionShielded cellsAntechamberParticle beam

An objective of this particle beam projection chamber is to ensure that after a patient is positioned on somewhere other than the patient bed in a projection region used when actually projecting a particle beam, the amount of positional deviation in the positioning state of the patient is within an allowable range when being moved to the projection region from the entrance of the projection chamber. This particle beam projection chamber (20) comprises: a projection execution chamber (22) wherein a wherein a patient bed (2) comprising a detachable top board (5) and a drive device (9) for driving the top board (5) is placed, said projection execution chamber (22) being surrounded by a shield wall (21); a path (23) which is disposed on a side in the shield wall (21) where an antechamber (25) in which a patient (45) is to be positioned on the top board (5) is located, such that the patient (45) positioned on the top board (5) may pass into the projection execution chamber (22) by a conveyance device (10) in a straight line; and a shield door (24) which shields radiation leaking at or less than a managed value when the particle beam is projected, said shield door (24) being provided at a projection chamber entrance (30) which is located on the antechamber (25) side of the path (23).

Owner:HITACHI LTD

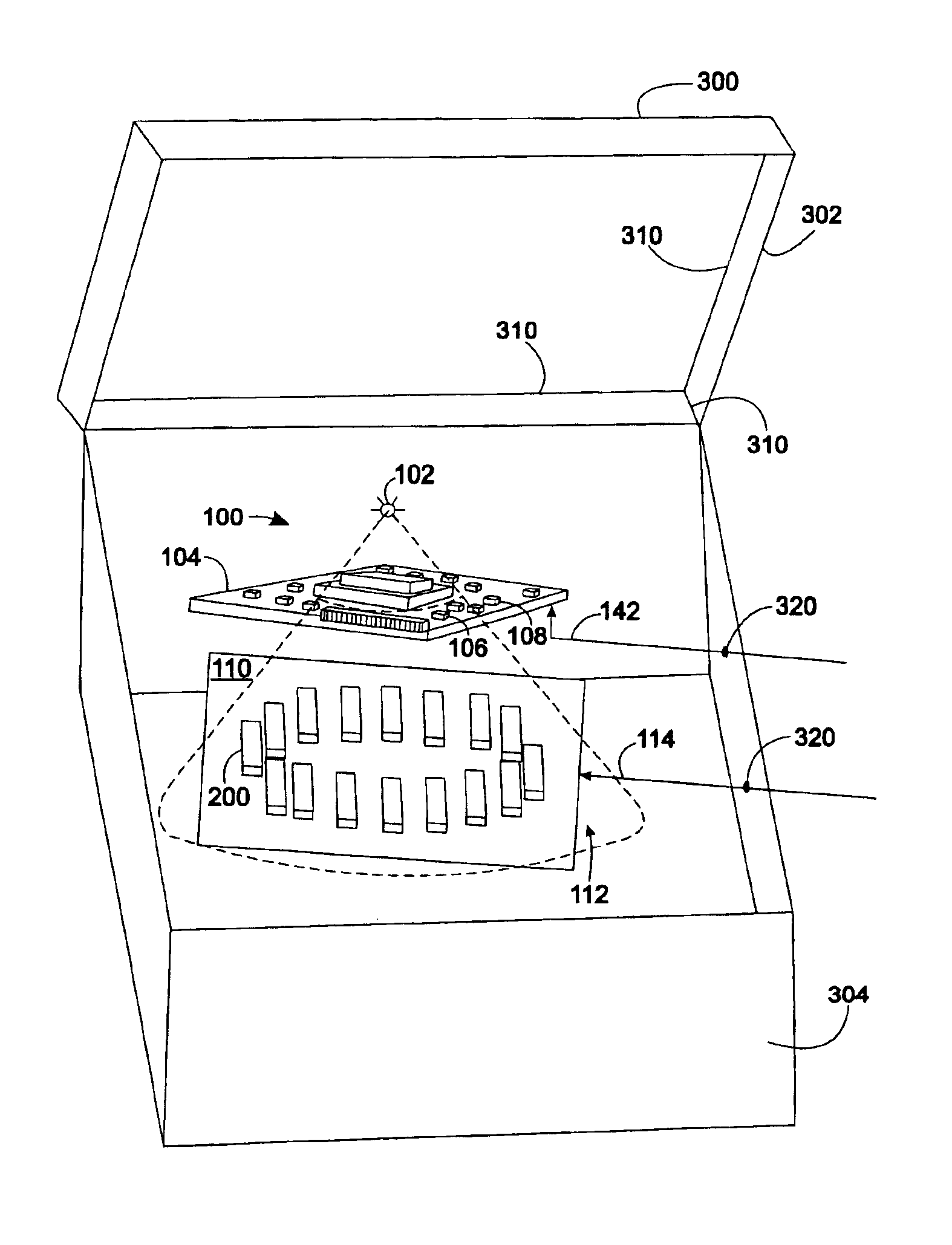

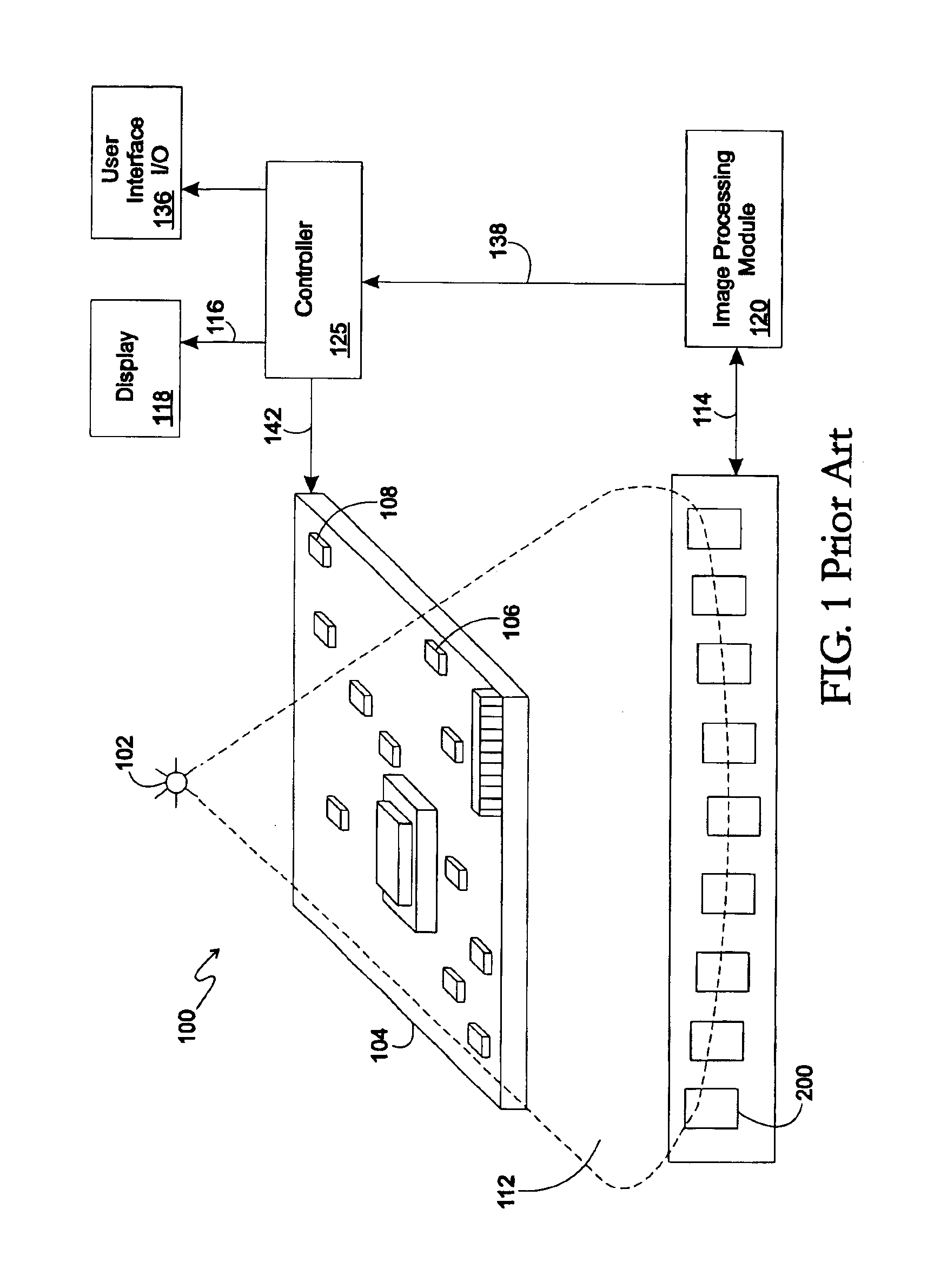

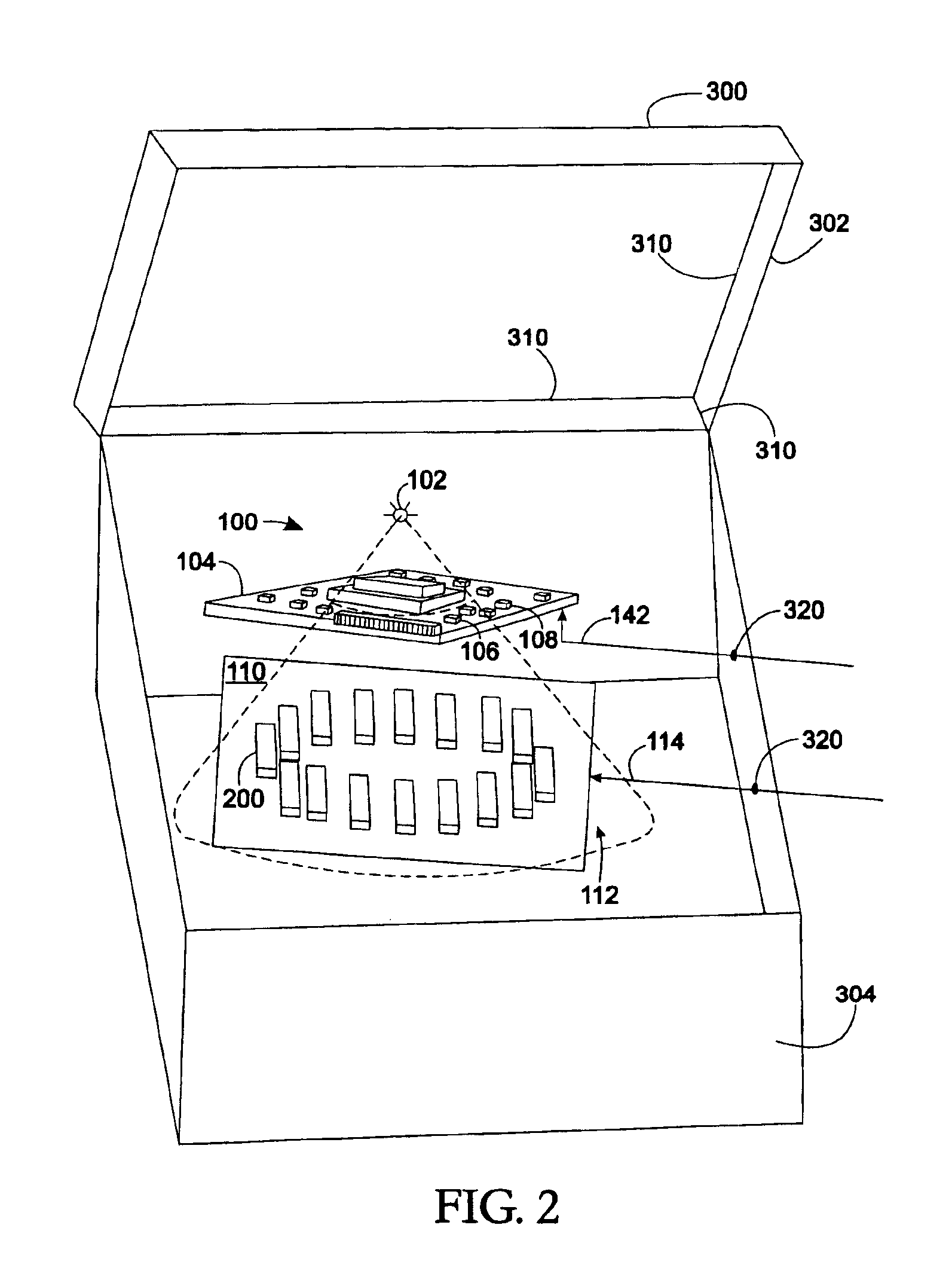

Iron ore composite material and method for manufacturing radiation shielding enclosure

InactiveUS6891179B2Radiation/particle handlingElectrode and associated part arrangementsHigh densityX-ray

Materials and methods of manufacturing radiation shielded enclosures is presented that may replace the use of lead, granite and other heavy, expensive, toxic, environmentally unfriendly or otherwise undesirable materials and manufacturing methods. The present invention provides a high-density radiation shielding enclosure manufactured by cold casting a liquid refined iron ore or taconite composite material into a mold of an enclosure of an appropriate shape and size to house an x-ray imaging system. The method of manufacture may include applying an iron ore or tungsten composite caulking compound to the radiation shielding enclosure in order to seal any radiation leaks in the radiation shielding enclosure.

Owner:AGILENT TECH INC

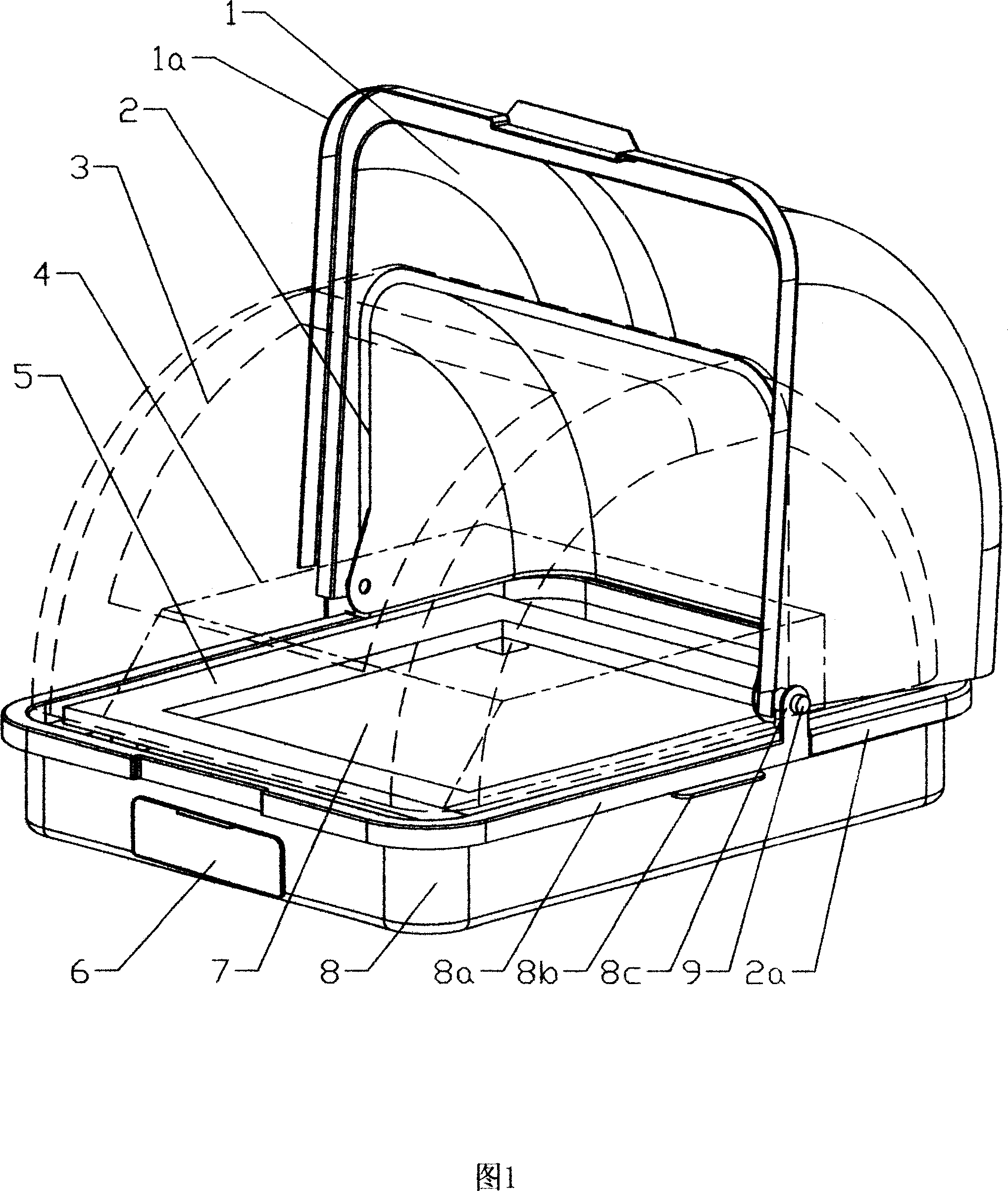

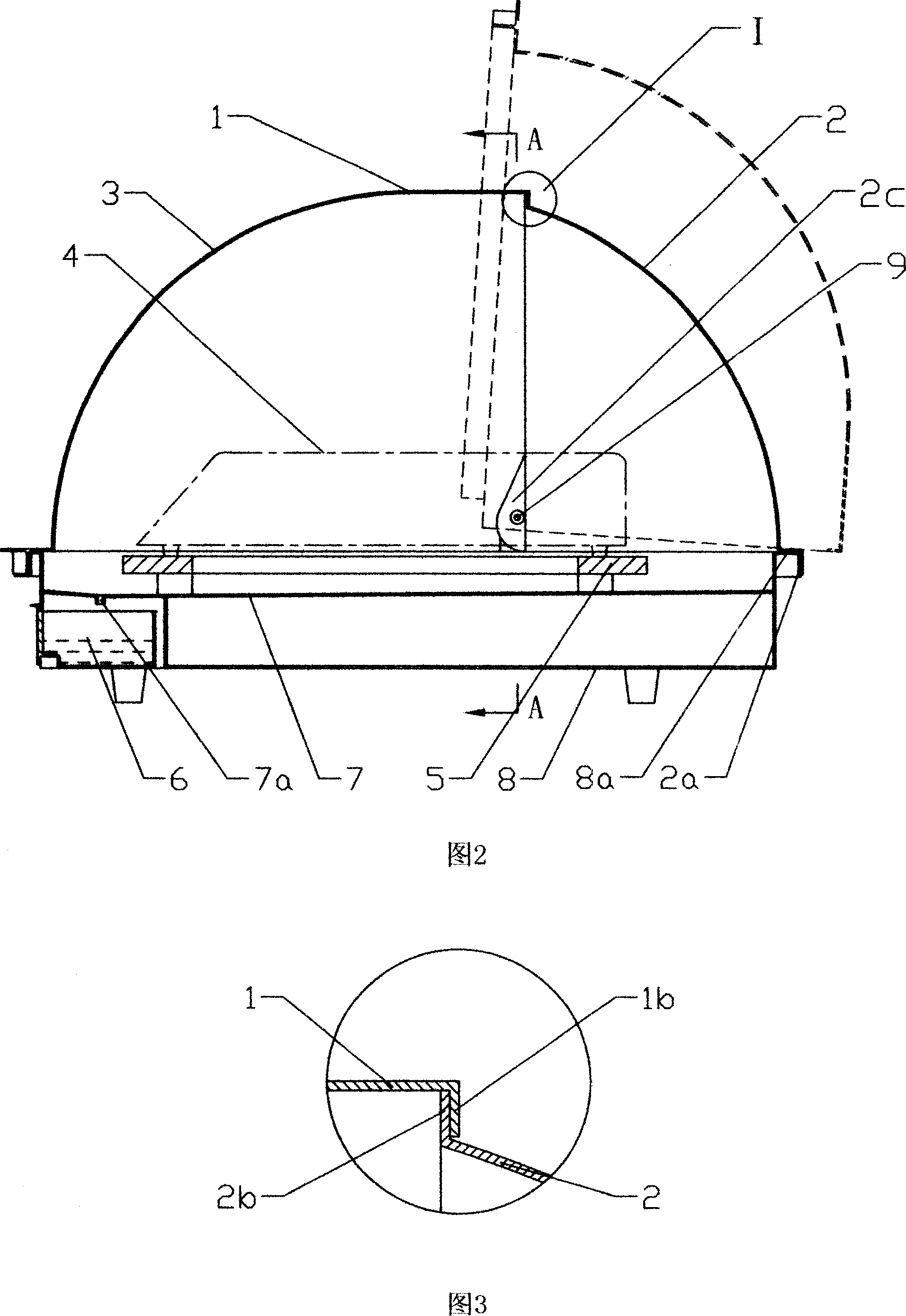

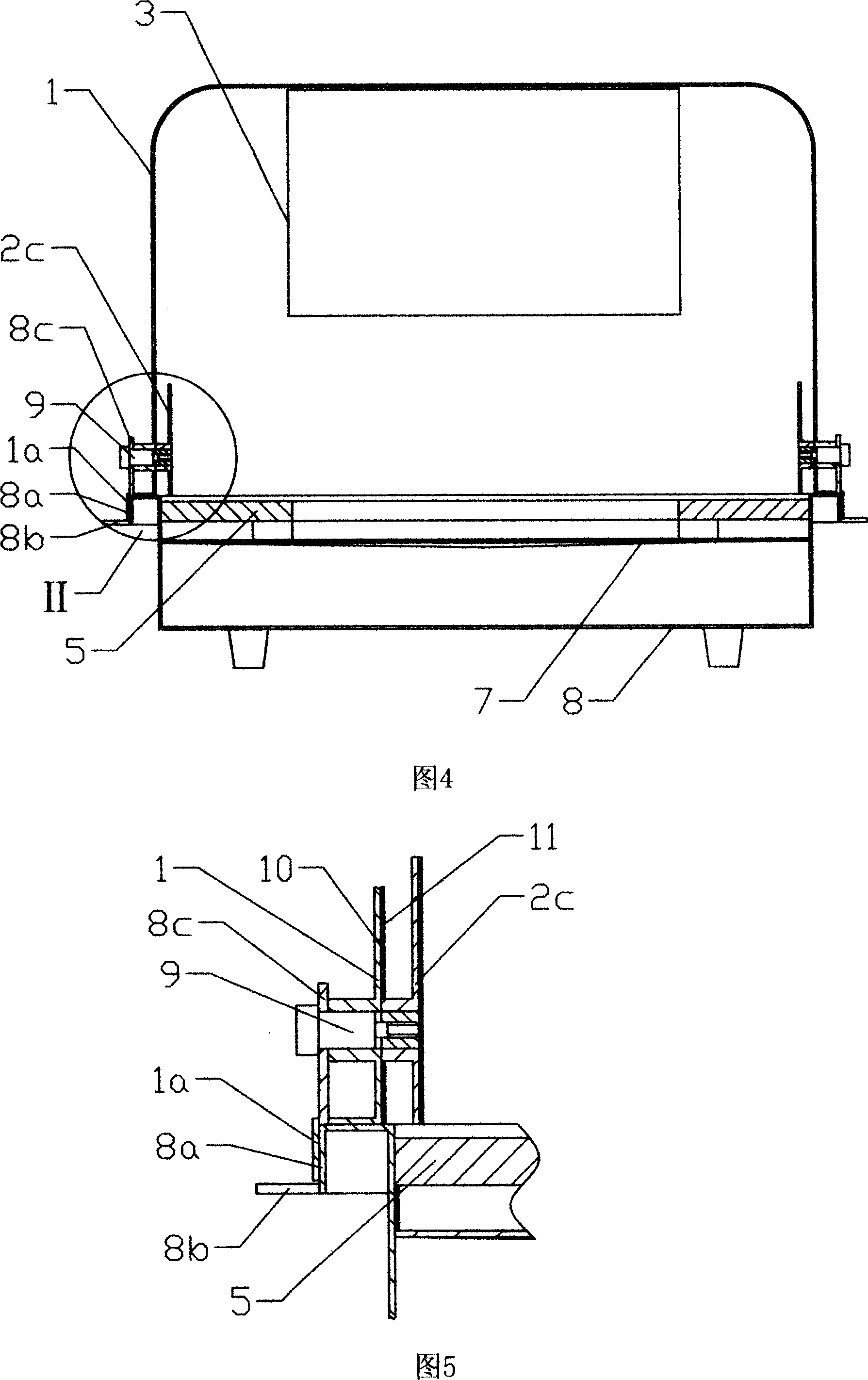

Tiltable anti-radiation cover for household kitchen electric appliance

InactiveCN1988793AHarm reductionDon't worry about harmMagnetic/electric field screeningScreening apparatusMicrowaveEngineering

A radiation shield for kitchen household appliances can be upturned. It relates to a radiation protection device, and can be used for all radiate kitchen appliances, in particular electromagnetic cooker or microwave cooker, in which, it can be avoid for microwave and electromagnetic radiation leakage to harm users. It is convenient and not affects the use of electrical appliances. It consists of the chassis hinged by pieces of thread, front and behind covers, which form a closed radiation space together. Its characteristics are: there are radiation protection coating on the chassis, the inside wall of front and behind covers to realize absorption and resistance of electromagnetic wave and microwave, there is a layer of water inside the radiation protection coating, there is a water tray with a drainage hole in front in the chassis, and there is a water box inserted under the drainage hole.

Owner:王宝根

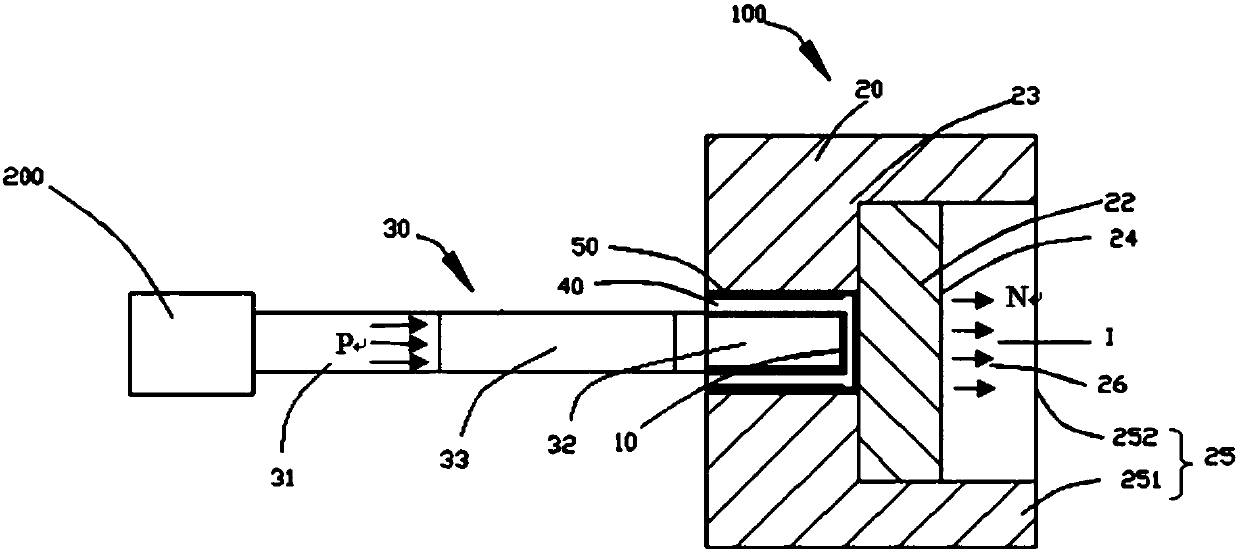

Neutron capture therapy system

The neutron capture therapy system provided by the present application includes an accelerator for generating a charged particle beam, a neutron generating portion that reacts with the charged particle beam to generate a neutron beam, and a beam shaping body. The beam shaping body includes a receiving portion, a retarding body, a reflector, a shielding device and a beam outlet, the receiving portion is provided with a vacuum tube connected to the accelerator, and the neutron generating portion is disposed at an end of the vacuum tube, the vacuum tube transmits the charged particles acceleratedby the accelerator to the neutron generating portion to cause the neutron generating portion to react with the charged particle beam to form the neutron beam, the neutron generating portion moves between a first position and a second position, in the first position, the neutron generating portion reacts with the charged particle beam to generate neutrons, in the second position, the neutron generating portion is detached from the beam shaping body, and the beam shaping body and the shielding device keep the neutron generating portion in the shielding through movement from the first position to the second position to prevent that the radiation leaked from the neutron generating portion is exposed to the worker.

Owner:NEUBORON MEDTECH

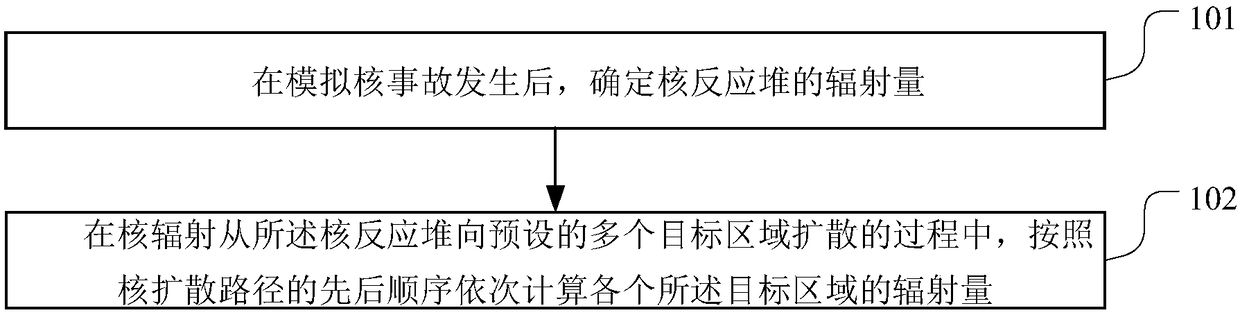

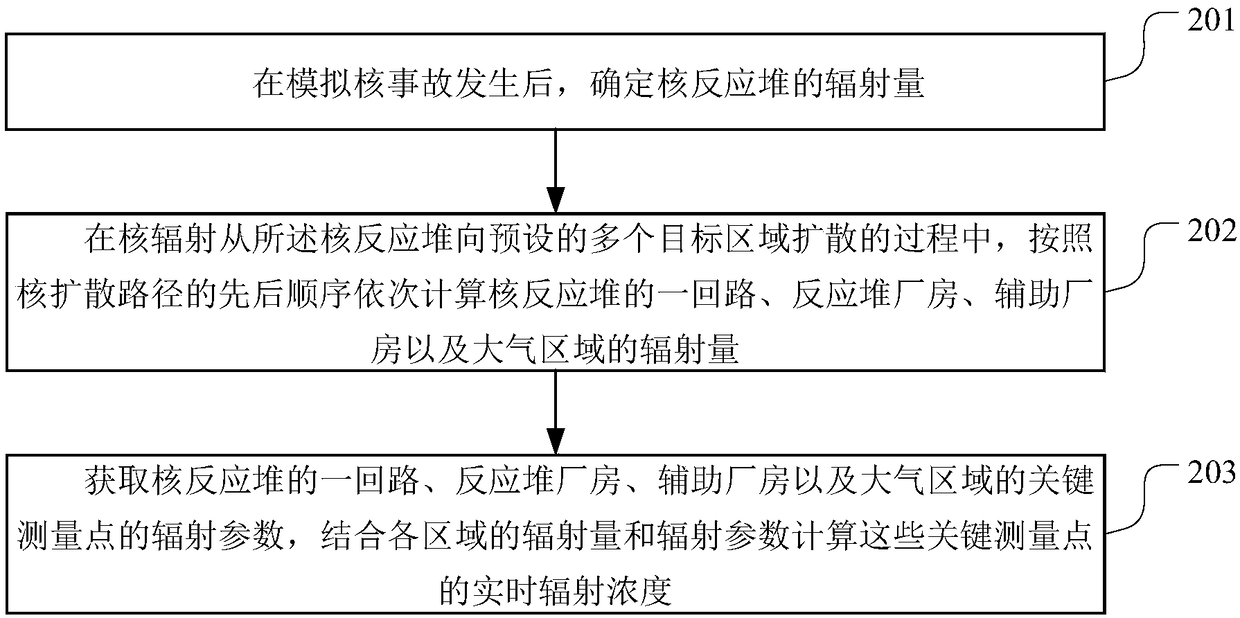

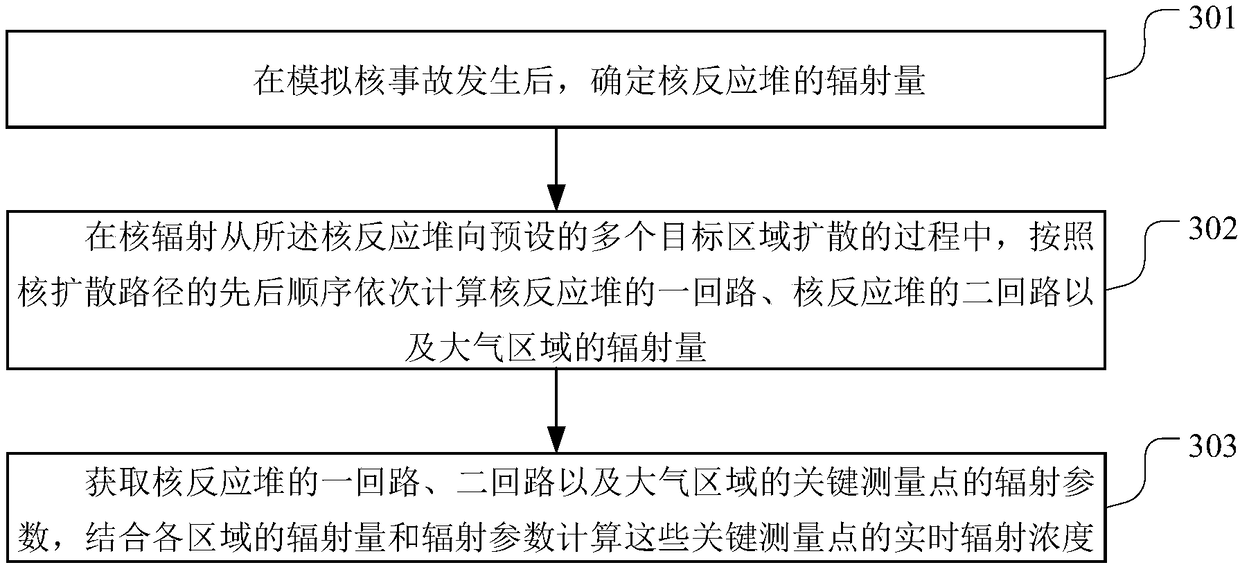

Nuclear accident radiation data simulation method and apparatus, terminal device and storage medium

ActiveCN108268694AAccurately simulate radiation doseImprove the effectiveness of exercisesNuclear energy generationNuclear monitoringDiffusionNuclear radiation

The invention relates to the technical field of nuclear power plant accident emergency and provides a nuclear accident radiation data simulation method and apparatus, a terminal device and a storage medium. The method comprises the steps of determining a radiation quantity of a nuclear reactor after a nuclear accident is simulated; in a process that nuclear radiation is diffused to preset target regions from the nuclear reactor, calculating radiation quantities of the target regions in sequence according to a sequence of nuclear diffusion paths, wherein the nuclear diffusion paths consist of the nuclear reactor and the target regions, and the nuclear reactor is located at the head end of each nuclear diffusion path, and the radiation quantity of each target region is obtained by calculation according to the radiation quantity of the former region, the radiation quantity of radiation deposited in the former region and the radiation quantity of radiation leaking to the latter region. Compared with a conventional method for setting the radiation quantities of the regions by depending on experience values, the method has the advantages that the simulated radiation quantities of the regions can be obtained more accurately and the nuclear accident training effect is improved.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +4

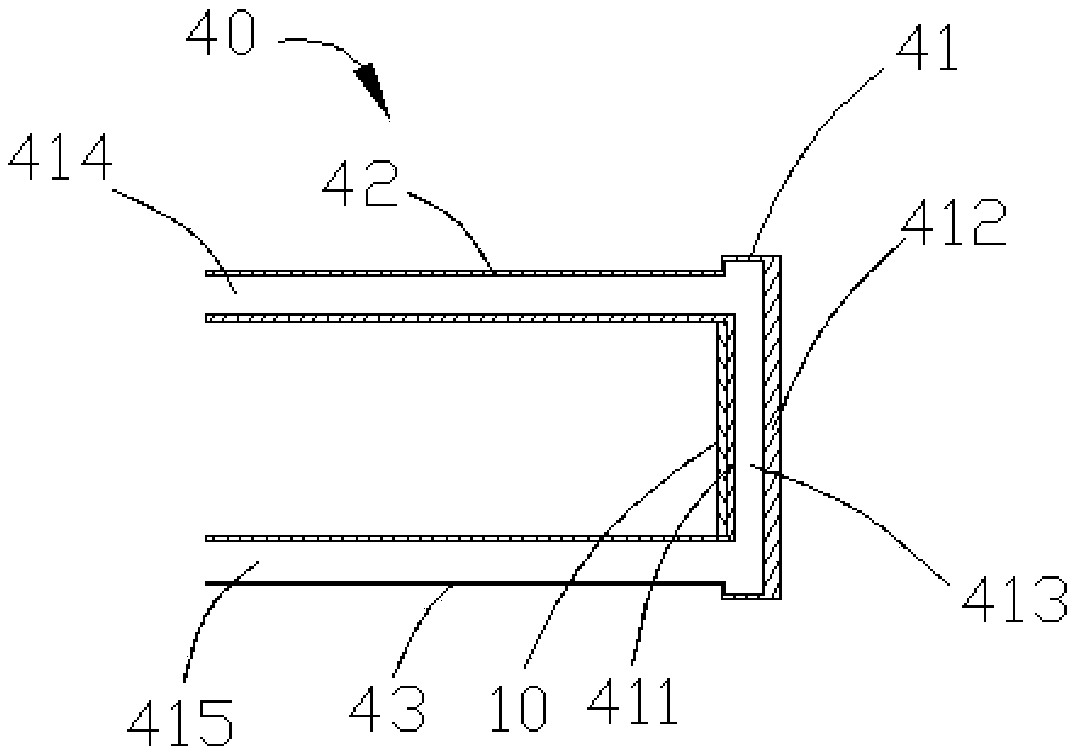

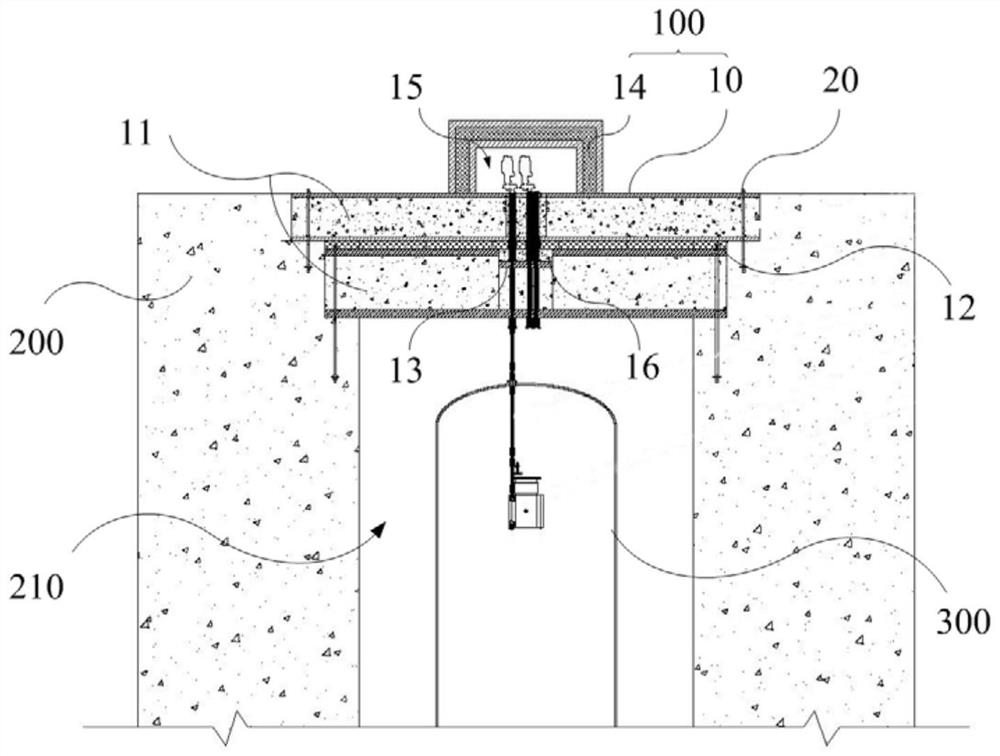

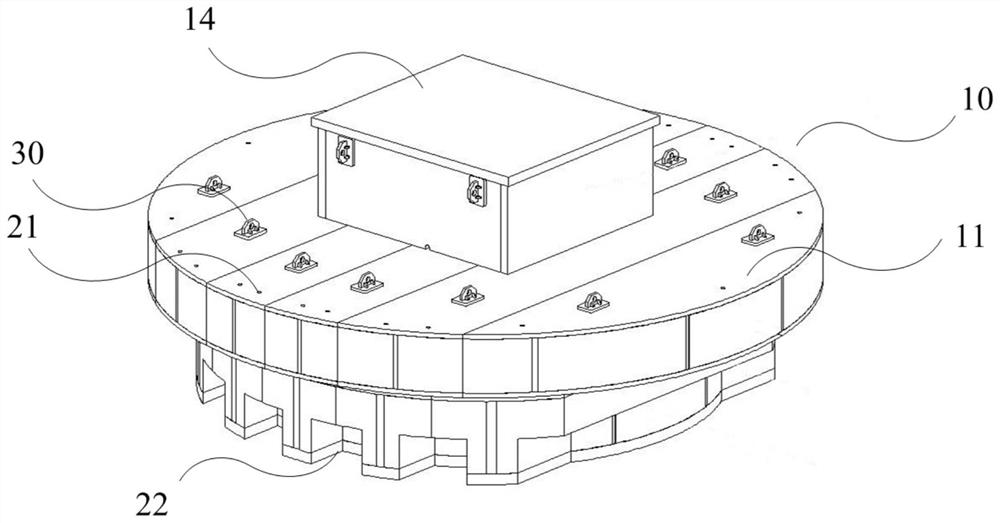

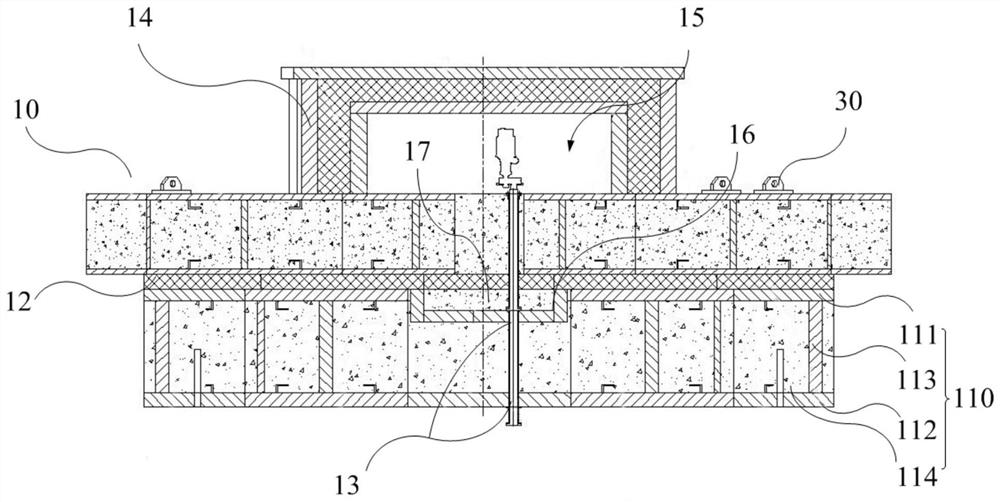

Shielding assembly for reactor and shielding structure thereof

ActiveCN111627575AEnsure personal safetyGuarantee property securityNuclear energy generationShieldingNuclear engineeringAtomic physics

The invention discloses a shielding structure for a reactor accommodating structure and a shielding assembly with the shielding structure. The reactor accommodating structure defines an accommodatingcavity which is used for accommodating at least part of a reactor and is provided with an opening; the shielding structure comprises a shielding body, the shielding body is provided with a connectingpart, and the connecting part is used for being connected with the reactor accommodating structure to enable a shielding body to cover the opening, so that leakage of at least part of radiation generated by at least part of the reactor from the opening to the outside of the accommodating cavity is reduced. According to the shielding structure and the shielding assembly with the shielding structure, radiation leaked from the opening to the outside of the accommodating cavity is reduced, so that a good radiation shielding effect is achieved, and the personal and property safety of operating personnel is effectively guaranteed.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

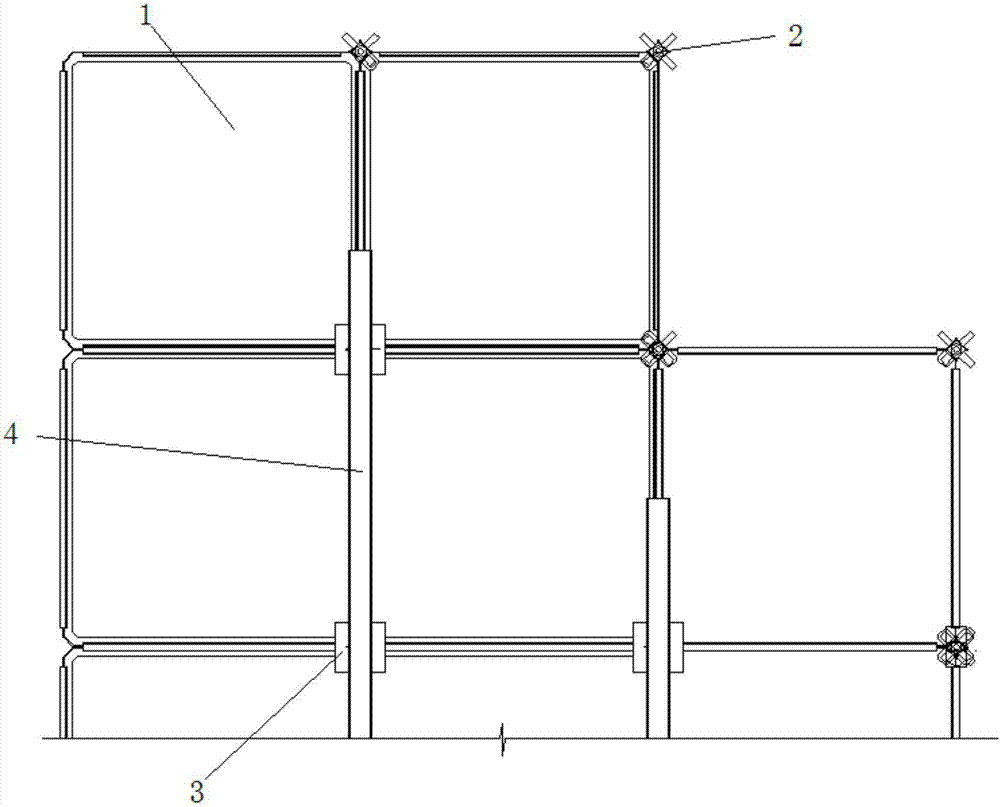

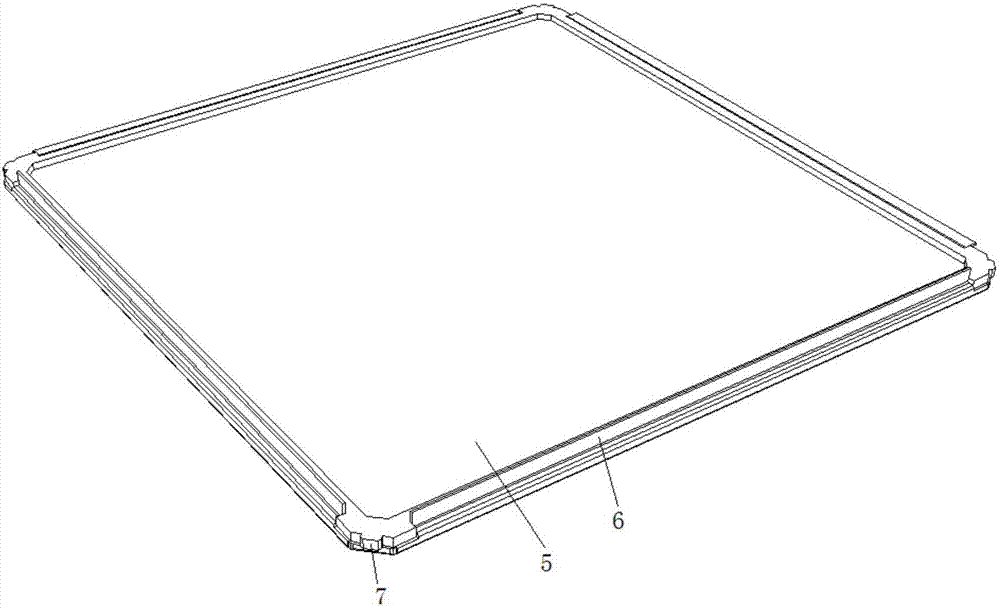

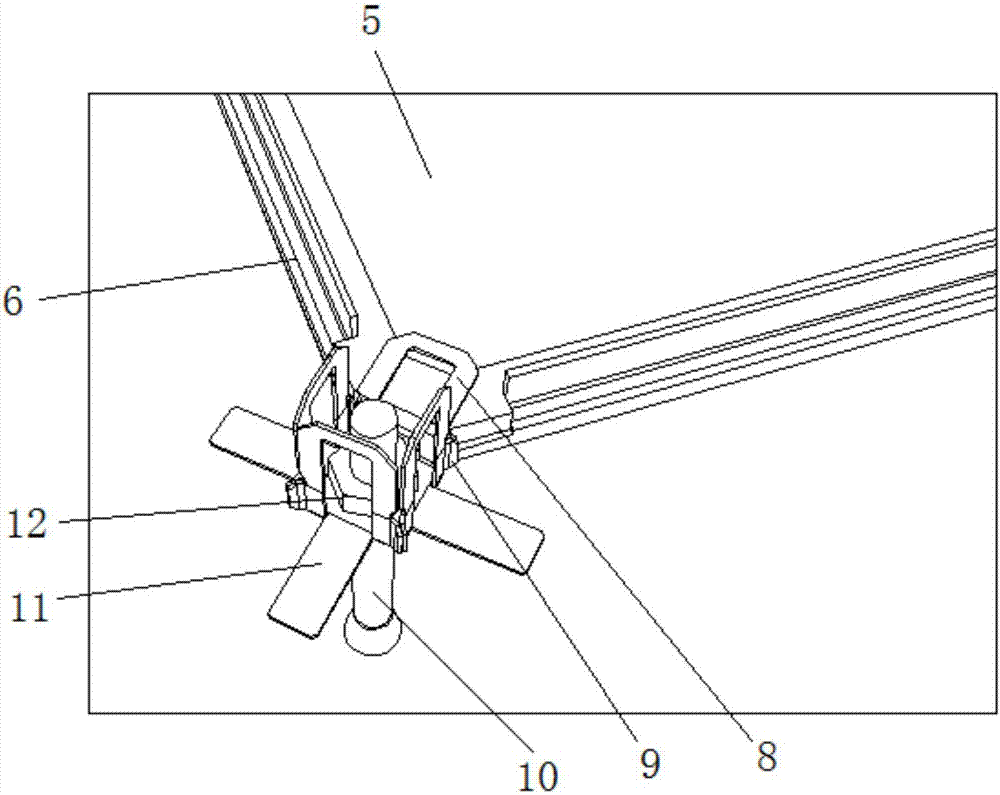

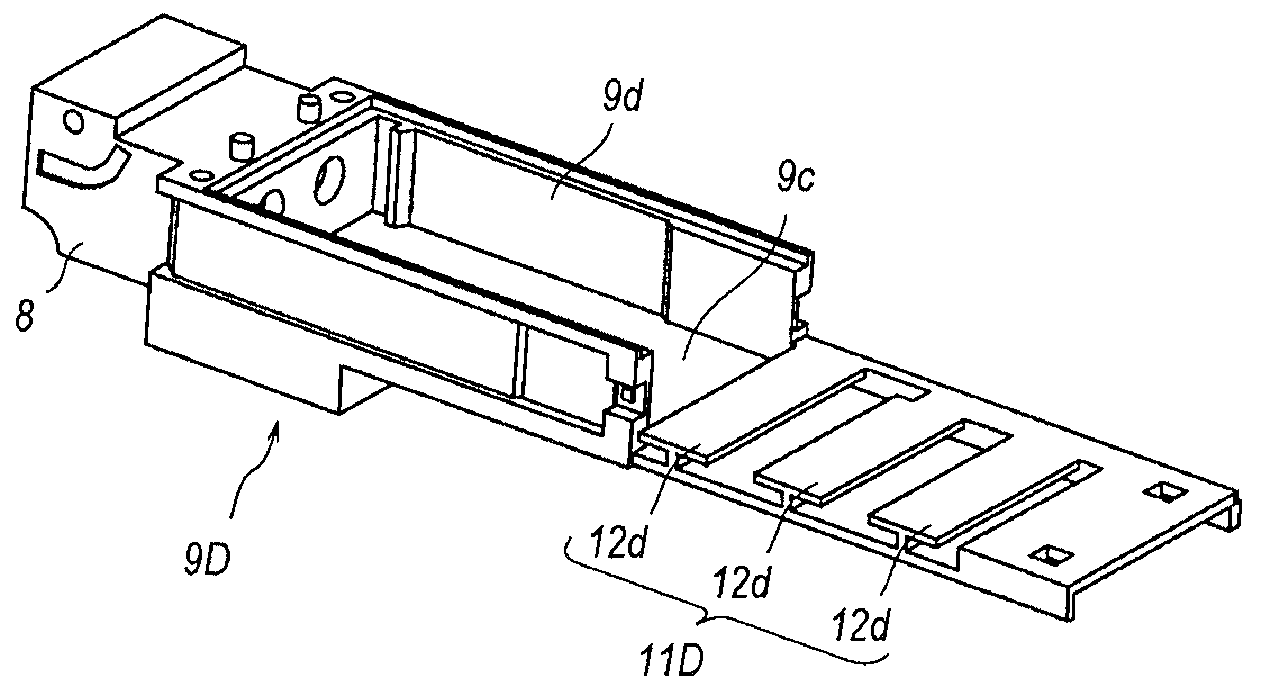

Modularized lead protection system

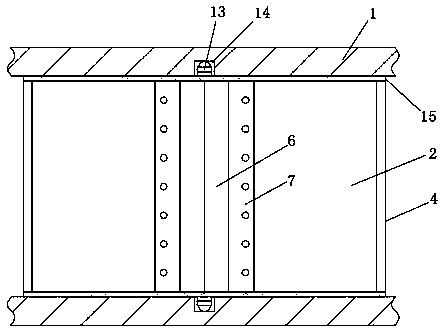

ActiveCN107327037APhysical health is not affectedAvoid deformationBuilding constructionsRadiation leakageEngineering

The invention relates to a modularized lead protection system comprising an installing structure face and a plurality of rectangular lead protection modules. Each rectangular lead protection module comprises a liner and a main protection lead plate, wherein the main protection lead plate wraps the bottom face of the liner and is fixedly connected with the liner. The edges of every two corresponding rectangular lead protection modules abut against each other to form a modularized lead protection plate. The four corners of the rectangular lead protection modules are each provided with a tenon. All the tenons corresponding to all joints on the modularized lead protection plate are connected together through joggle joint parts. Fixing parts fixing the modularized lead protection plate to the installing structure face penetrate through all the joggle joint parts to be arranged. A main protection lead plate abuts against the installing structure face. The modularized lead protection system is simple in structure and can be installed fast by a single person, material transport, construction labor intensity and labor cost are reduced, the effect that the health of an operator is not influenced is ensured, and radiation leakage is prevented effectively.

Owner:重庆奕欣医院管理有限公司

Optical transceiver having enhanced EMI tolerance

An optical transceiver that attenuates the EMI radiation leaked therefrom is disclosed. The optical transceiver includes a top cover and the bottom base to form a cavity into which a TOSA, a ROSA, and a circuit are set. At least one of the top cover and the bottom base provides a combed structure in a rear portion of the optical transceiver, where the combed structure has a plurality of T-shaped fins to attenuate the EMI radiation.

Owner:SUMITOMO ELECTRIC IND LTD

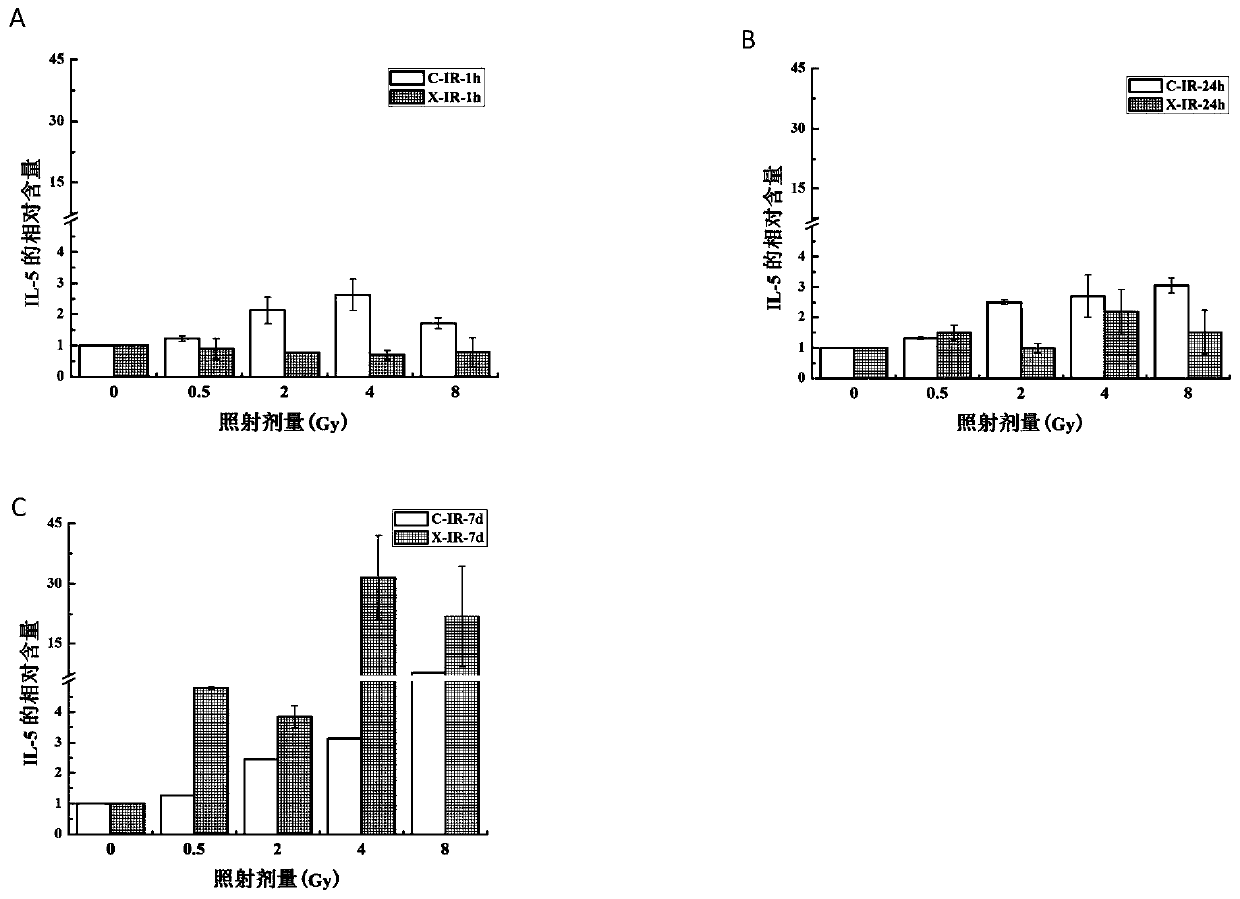

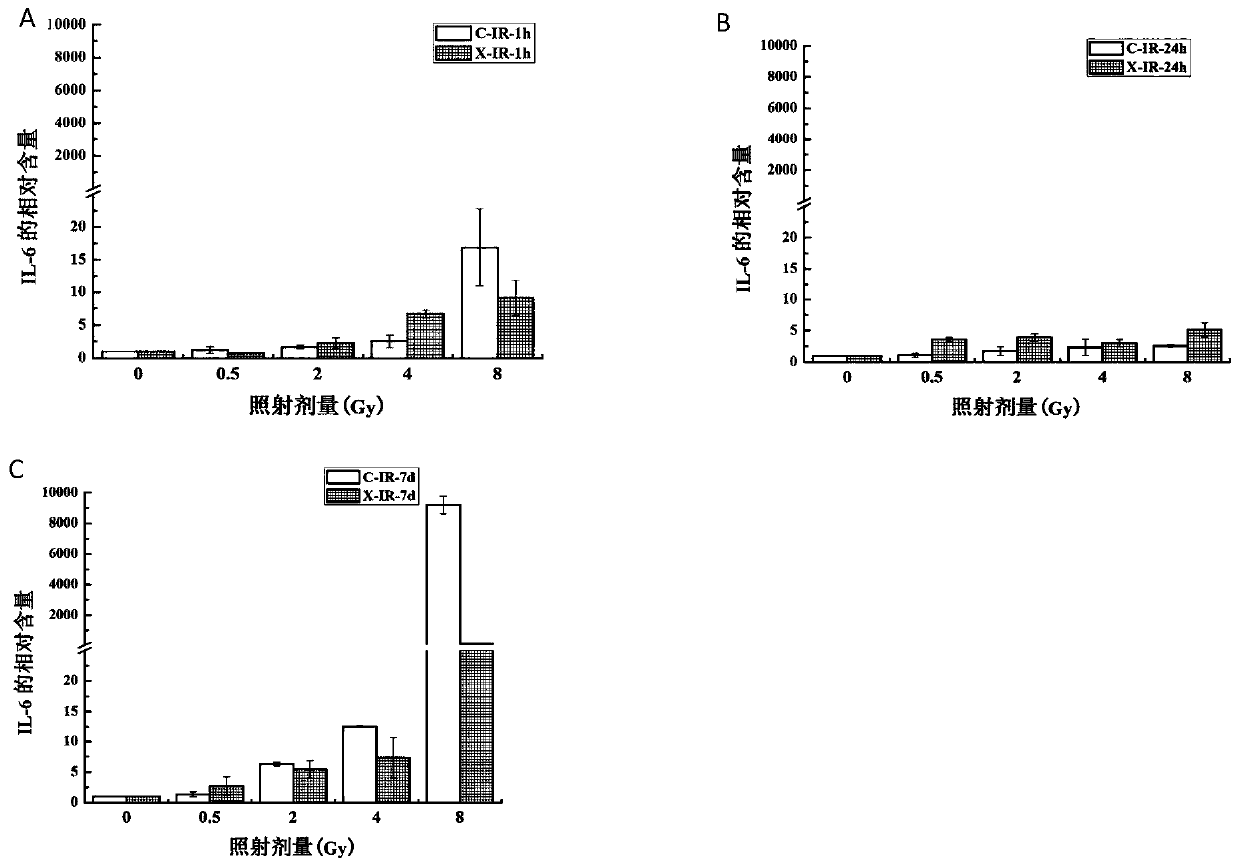

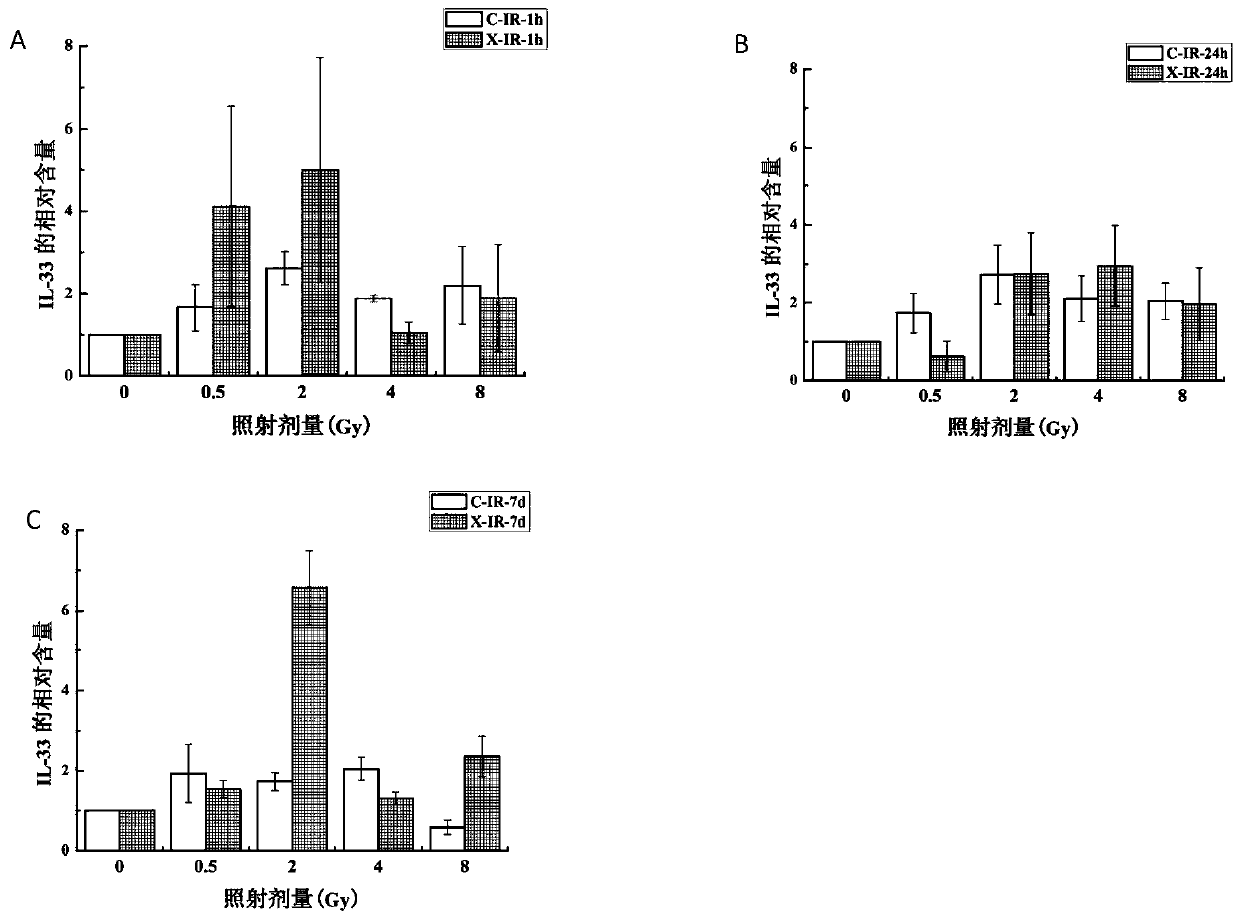

Combination of five cytokines as ionizing radiation injury biomarker

ActiveCN110672860AImprove throughputIncreased sensitivityDisease diagnosisBiological testingCytokineRadiation hazard

The invention discloses five cytokines as ionizing radiation injury biomarkers. The invention provides an application of a combination of five cytokines IL-5, IL-6, IL-10, IL-15 and IL-33 as a biomarker in monitoring animal individual harm or crowd harm caused by radiation leakage. According to the method, a serum sample of an irradiated victim is taken as a detection object, and blood can be collected at any time after irradiation for detection and evaluation, thereby achieving the timely evaluation; based on the advantages of MSD equipment, the detection with low sample size requirement, high flux and high sensitivity can be realized. According to the method, the required sample amount for detection is small, five strictly analyzed and screened radiation damage biomarkers are detected ata time, the low-cost, rapid and efficient detection function can be achieved, and the service radiation hazards are evaluated in time.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

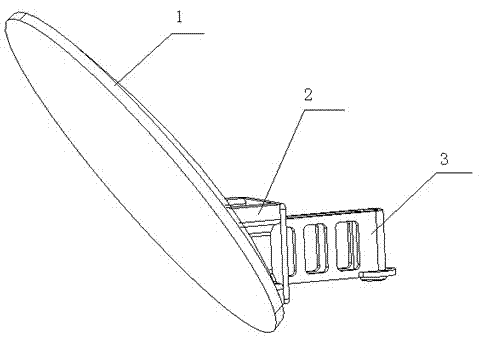

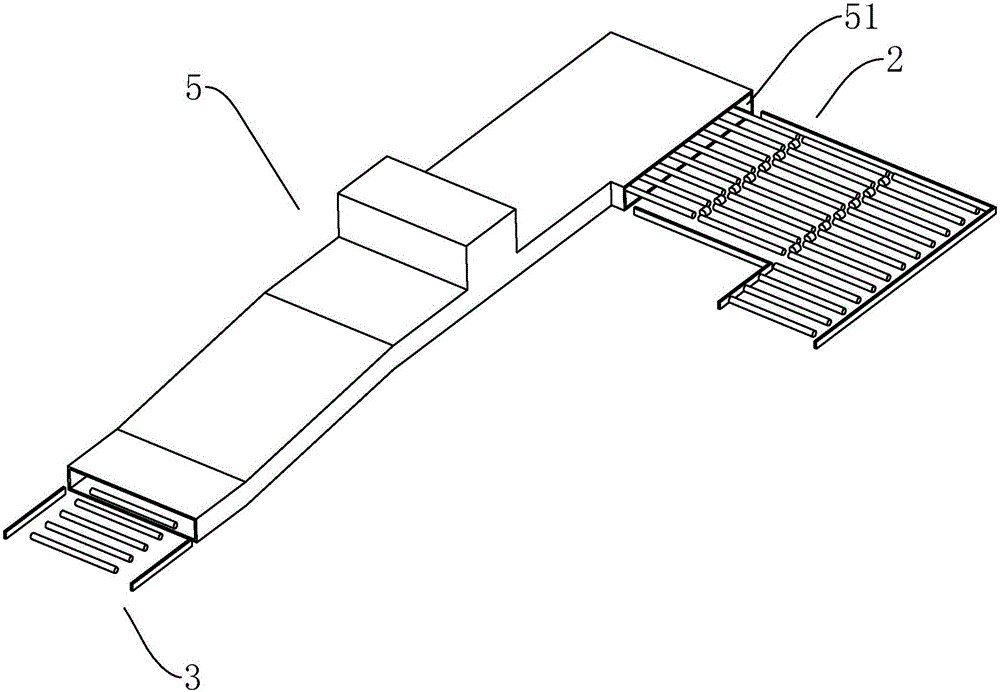

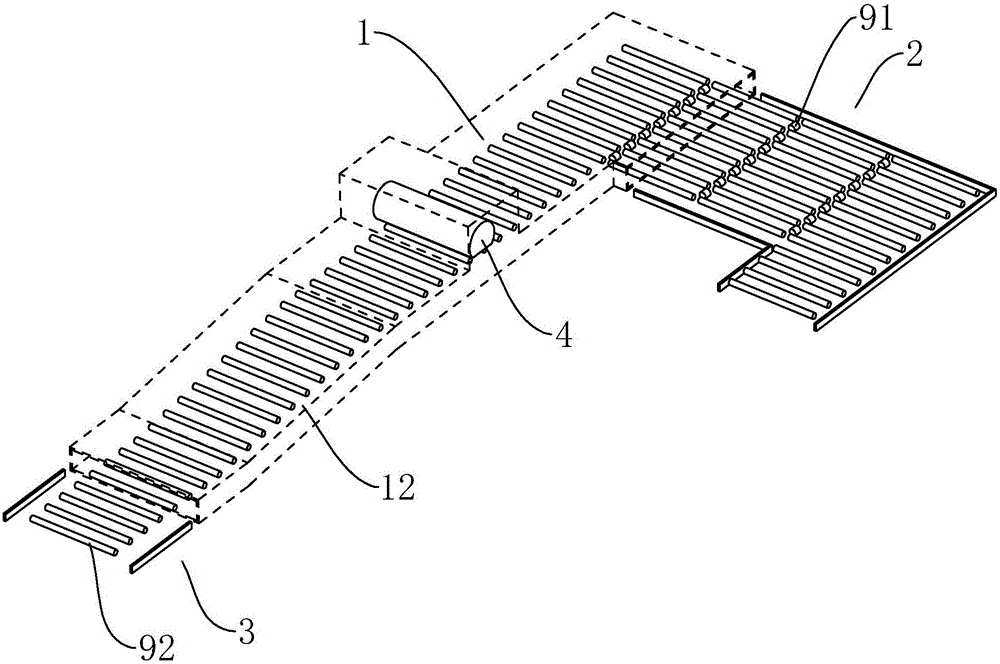

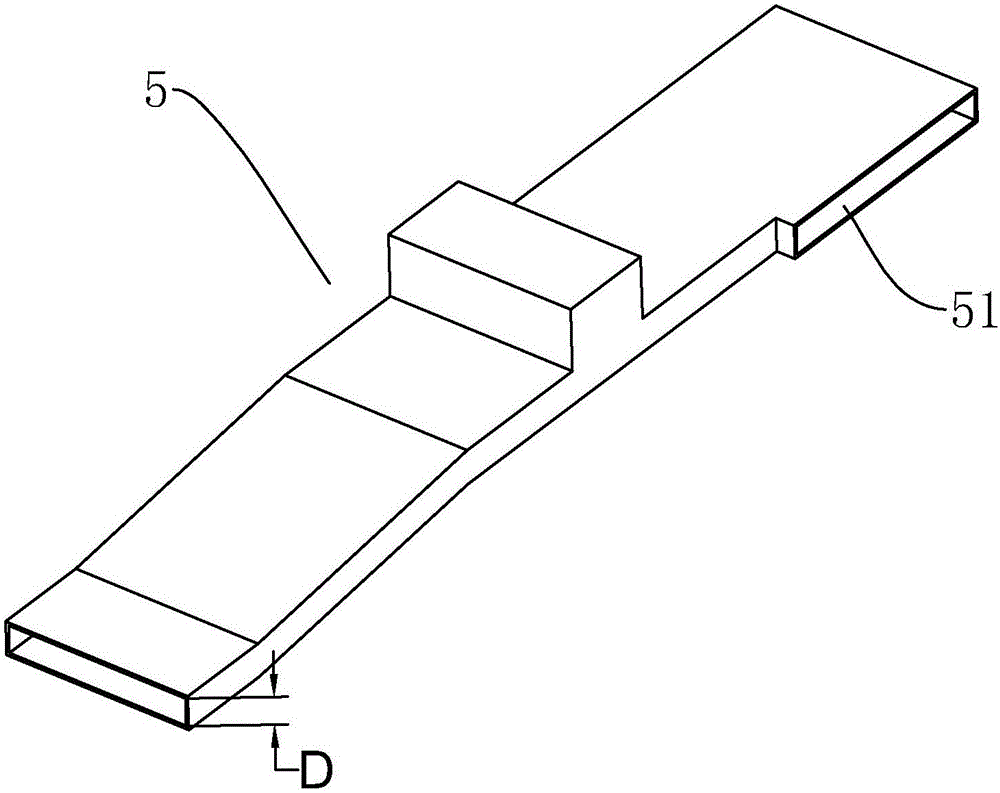

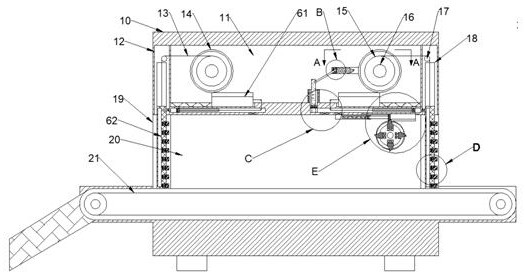

Anti-radiation shielded conveying passageway used for electron beam curing of plane panel coating

The invention discloses an anti-radiation shielded conveying passageway used for electron beam curing of plane panel coating. The anti-radiation shielded conveying passageway comprises a radiation passageway, a feed passageway and a discharge passageway. An electron beam emitting device is arranged on the radiation passageway. A shielding shell is arranged on the radiation passageway. The feed passageway communicates to the radiation passageway from the side face of the portion, located at the feed end of the radiation passageway, of the shielding shell. The discharge passageway is lower than the radiation passageway. The radiation passageway is connected to the discharge passageway through an oblique discharge connection passageway. The end portion of the shielding shell extends to cover the oblique discharge connection passageway. Most of bremsstrahlung generated during work is emitted along the plane of the radiation passageway. Because a feed port of the shielding shell is formed in the side face and a small labyrinth is formed, leaking radiation is effectively reduced; by means of the obliquely-downward oblique discharge connection passageway and the shielding shell, radiation leaking from a discharge port is reduced, and harm to human bodies is avoided; and it can also be ensured that panel workpieces roughly keep in the horizontal state before entering the curing procedure, the thicknesses of coating layers of all positions on the workpieces keep uniform, and the curing effect of coatings is good.

Owner:中山易必固电子束科技有限公司

Radiation-proof door for medical radiology department

InactiveCN107740665AEasy to open and closeEasy to useRadiation protectionWindow/door framesMedical imagingMedical device

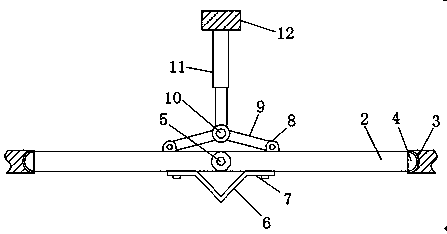

The present invention involves the field of medical equipment technology, especially for radiation protection for a medical radiology department. There are connecting ears on the outer wall of the two radiation -proof sets.There is a rotating shaft in the turning connection, and the top of the support pillar is fixed on the top wall. The end of the hinge shaft is installed with universal roller. The protective device includes two horizontal connectors.On the radiation panel, there are V -shaped folding plates between the two horizontal connecting boards, and the hinge shaft is located on the inside of the V -shaped folding plate.The medical radiology department uses radiation protection, easy to open and close, is convenient to use, does not need to be manually operated, brings convenience to the staff's work, has a good sealing effect, can prevent radiation leakage and ensure the health of the staff.

Owner:成都名典匠心工业产品设计有限公司

Anti-stacking security check instrument capable of preventing radiation leakage

InactiveCN112363235AReduce leakageThorough inspectionShieldingNuclear radiation detectionRatchetWire wheel

The invention provides an anti-stacking security check instrument capable of preventing radiation leakage. The anti-stacking security check instrument comprises a machine body and a security check cavity in the machine body, the left wall and the right wall of the security check cavity are provided with entrances and exits communicating with the outside, the machine body is internally provided with a power cavity located on the upper side of the security check cavity, wire wheel shafts are rotationally arranged in the power cavity in a bilateral symmetry mode, a ratchet wheel is fixedly arranged on each wire wheel shaft, a first gear is fixedly arranged on each wire wheel shaft, a wire wheel is fixedly arranged on each wire wheel shaft, and a first sliding groove is formed in the rear wallof the power cavity. According to the invention, a lead curtain can be lifted within a certain range according to the size of a package, the opening area is reduced while the package enters or leavesthe security check instrument, radiation leakage of the security check instrument is prevented and reduced, the lead curtain is fixed and can only be opened by a machine and cannot be directly openedby people in the using process, meanwhile, the device can check whether multiple packages are stacked or not, and the packages are processed according to the stacking condition, so that the inspection of the security check instrument is more comprehensive and thorough.

Owner:福清市嘉泰电子科技有限公司

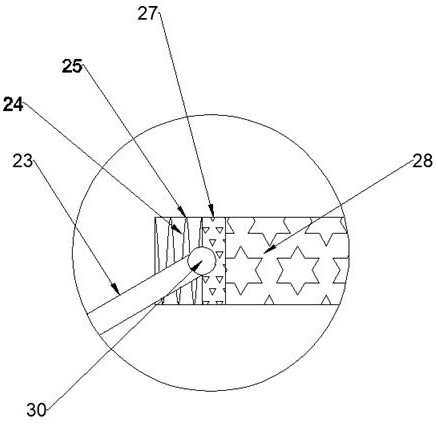

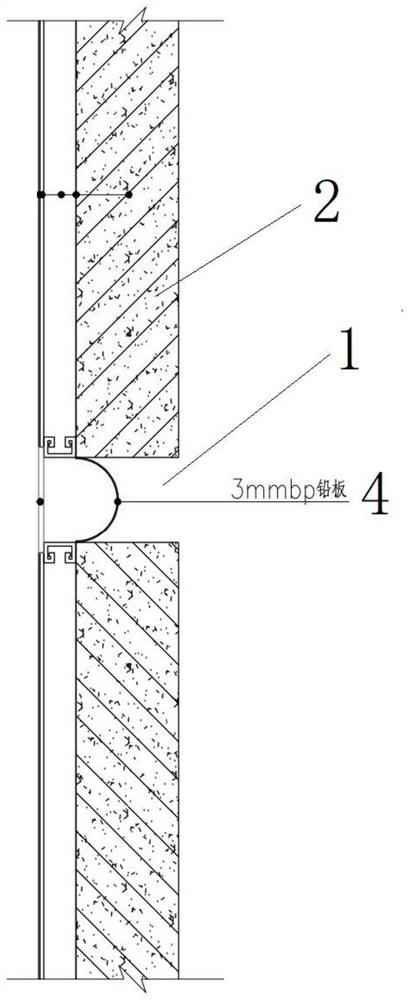

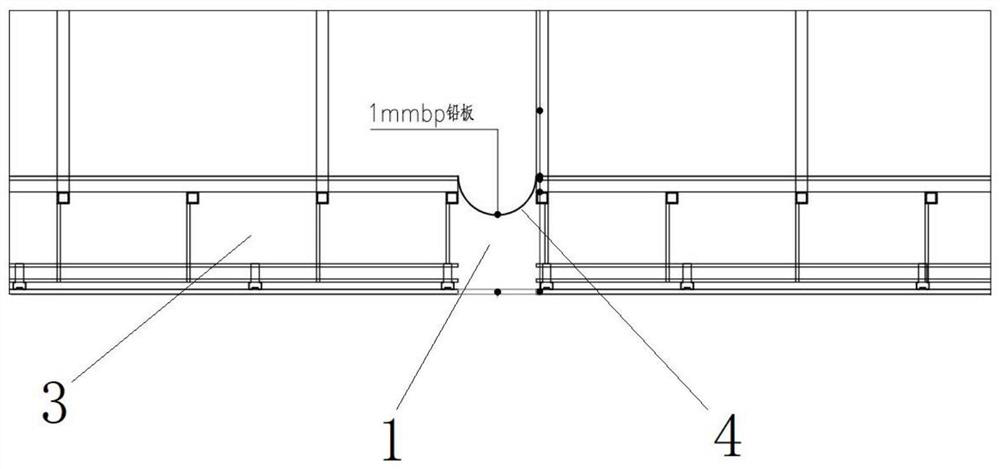

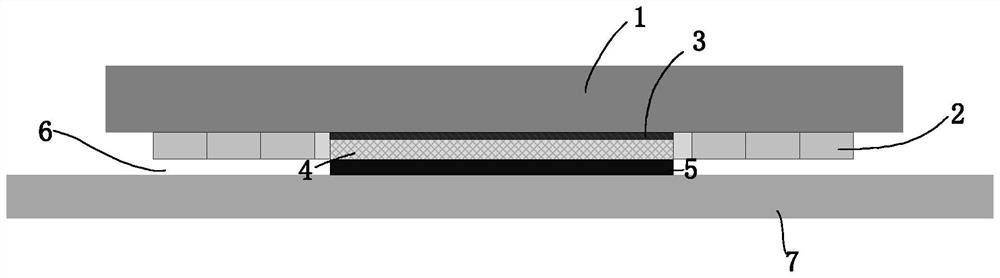

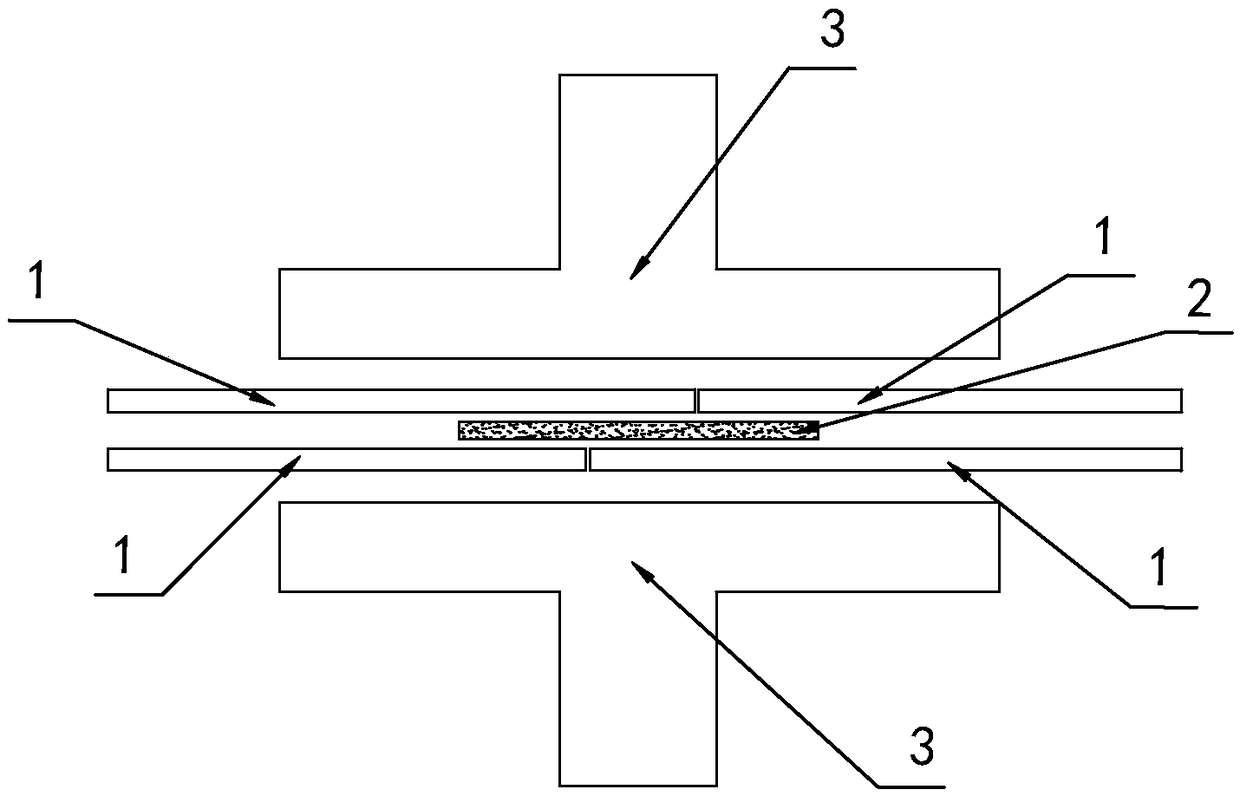

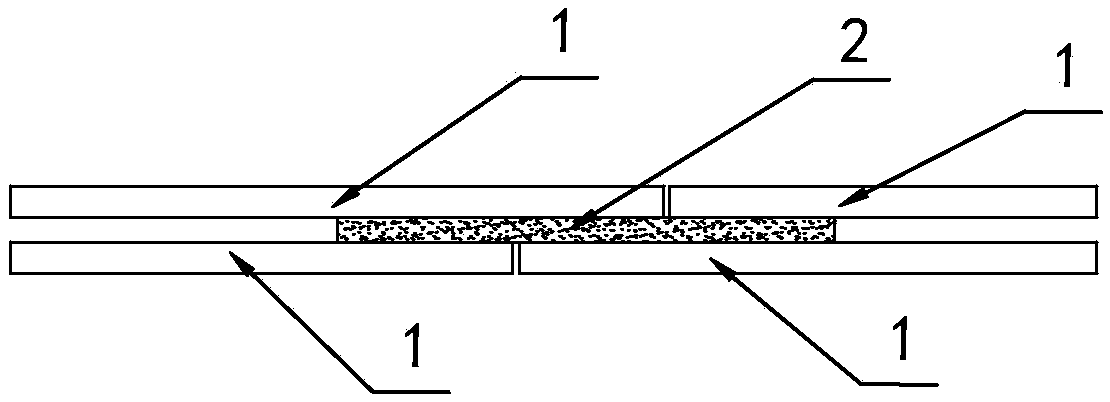

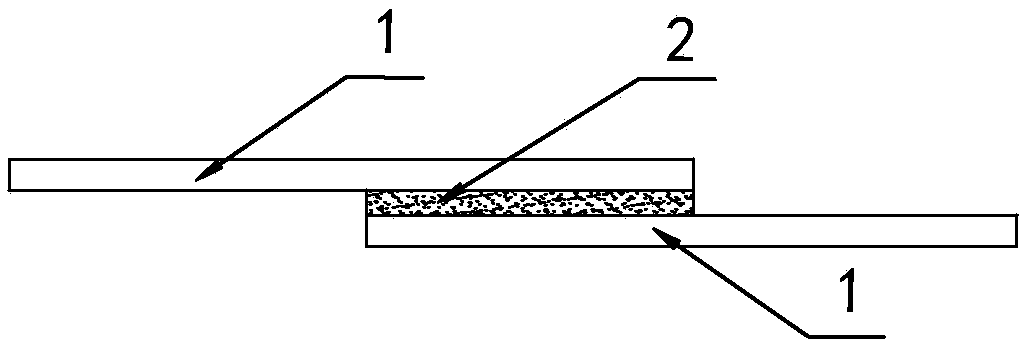

Filling device for expansion joint of ray protection engineering building structure

PendingCN113653203ASolve the defects of expansion jointsTechnical Issues in Preventing Radiation LeakageBuilding constructionsExpansion jointMechanical engineering

The invention relates to a filling device for an expansion joint of a ray protection engineering building structure, and belongs to the technical field of radiation protection. The filling device is filled in an expansion joint of a building construction surface, and a lead plate with an elastic structure is arranged in the expansion joint; and the cross section of the lead plate in the width direction is omega-shaped. According to the filling device, by arranging the filling lead plate with the elastic structure, expansion joints existing in a blank room are filled, and the technical problem of radiation leakage in the using process of a machine room is solved. According to the technical scheme, the manufacturing cost is low, and the effect of preventing the radiation leakage is safe and reliable.

Owner:上海黎东射线防护工程有限公司

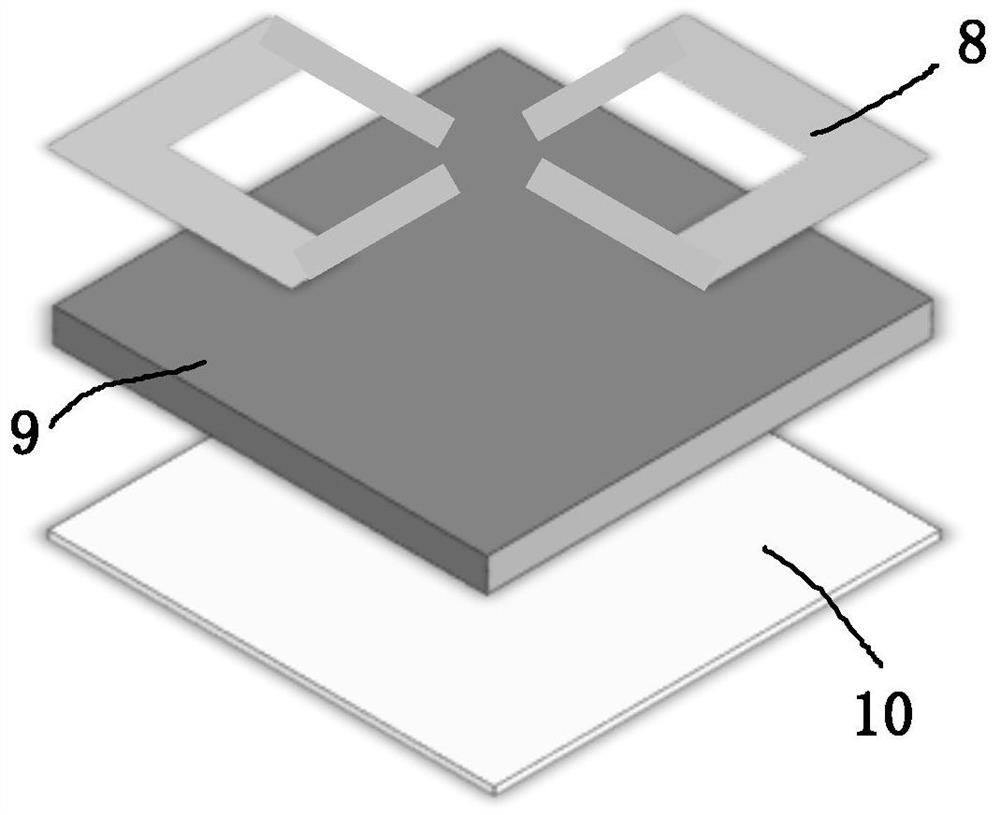

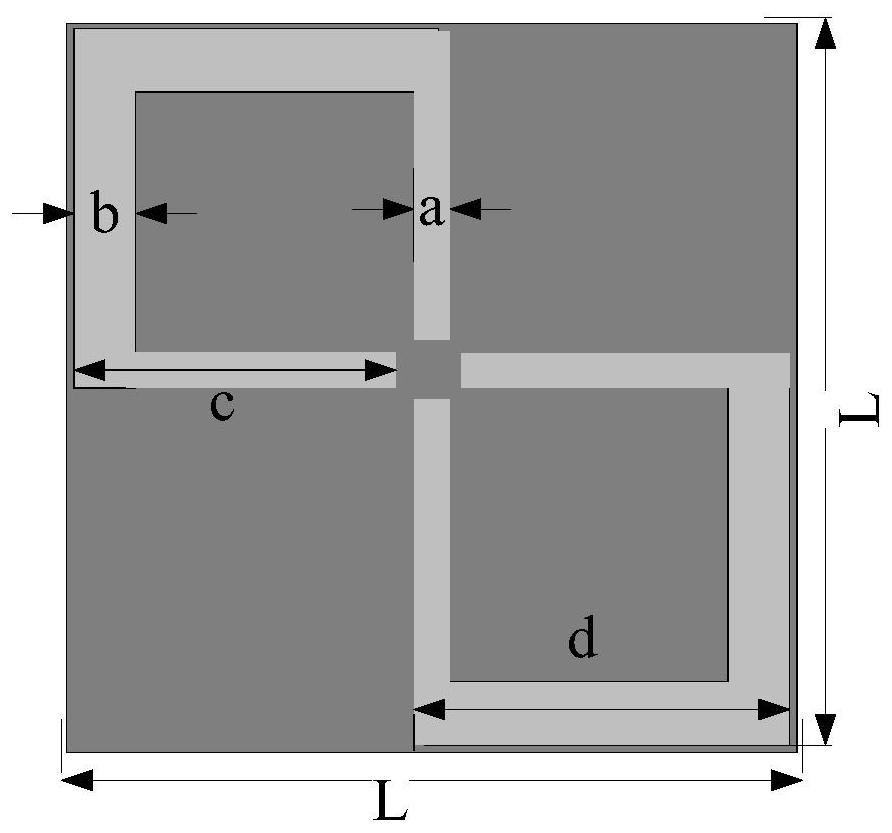

A high-performance electromagnetic radiation suppression structure

ActiveCN113286418BGuaranteed thermal conductivityLow costCross-talk/noise/interference reductionAntennasEngineeringThermal adhesive

Owner:海宁利伊电子科技有限公司

Optical transceiver having enhanced EMI tolerance

An optical transceiver that reduces the EMI radiation leaked therefrom is disclosed. The optical transceiver includes a top cover and the bottom base to form a cavity into which a TOSA, a ROSA, and a circuit are set. The top cover provides a combed structure in a rear portion thereof, where the combed structure has a plurality of fins with a distance preferably less that quarter wavelength λ / 4 of the noise wavelength to be reduced. The combed structure operates as a short stub for the electromagnetic wave traveling longitudinally in the cavity.

Owner:SUMITOMO ELECTRIC IND LTD

Cloth seaming structure, manufacturing technology and protective garment

PendingCN109393610AEffective all-round protectionAvoid harmProtective garmentSpecial outerwear garmentsManufacturing technologyRadiation leakage

The invention discloses a cloth seaming structure and a manufacturing technology of the cloth seaming structure. The cloth seaming structure comprises a plurality of cloth layers, the adjacent cloth layers are stacked at the seaming positions, gluing layers are arranged among the cloth layers at the seaming positions, so that needle holes can be effectively avoided, thus the production quality isimproved, and the production flow is simplified. Particularly, the cloth layers adopt radiation-proof cloth, and the gluing layers adopt hot melt adhesive. For the manufacturing technology, pressurizing and heating devices are used for carrying out hot melting gluing on the cloth layers stacked at the seaming positions, so that the production cost and production time are reduced, and the production efficiency is greatly improved. For a protective garment manufactured by adopting the manufacturing technology, the harm caused to the human body by radiation leakage leaking from needle holes at the seams can be avoided, and then the all-round protection can be effectively carried out on the human body.

Owner:GUANGZHOU VIEWMED MEDICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com