Cloth seaming structure, manufacturing technology and protective garment

A production process and fabric technology, applied in the field of fabric seam structure, production process and protective clothing, can solve problems such as leakage of radiation, human injury, etc., achieve comprehensive protection, reduce production time, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

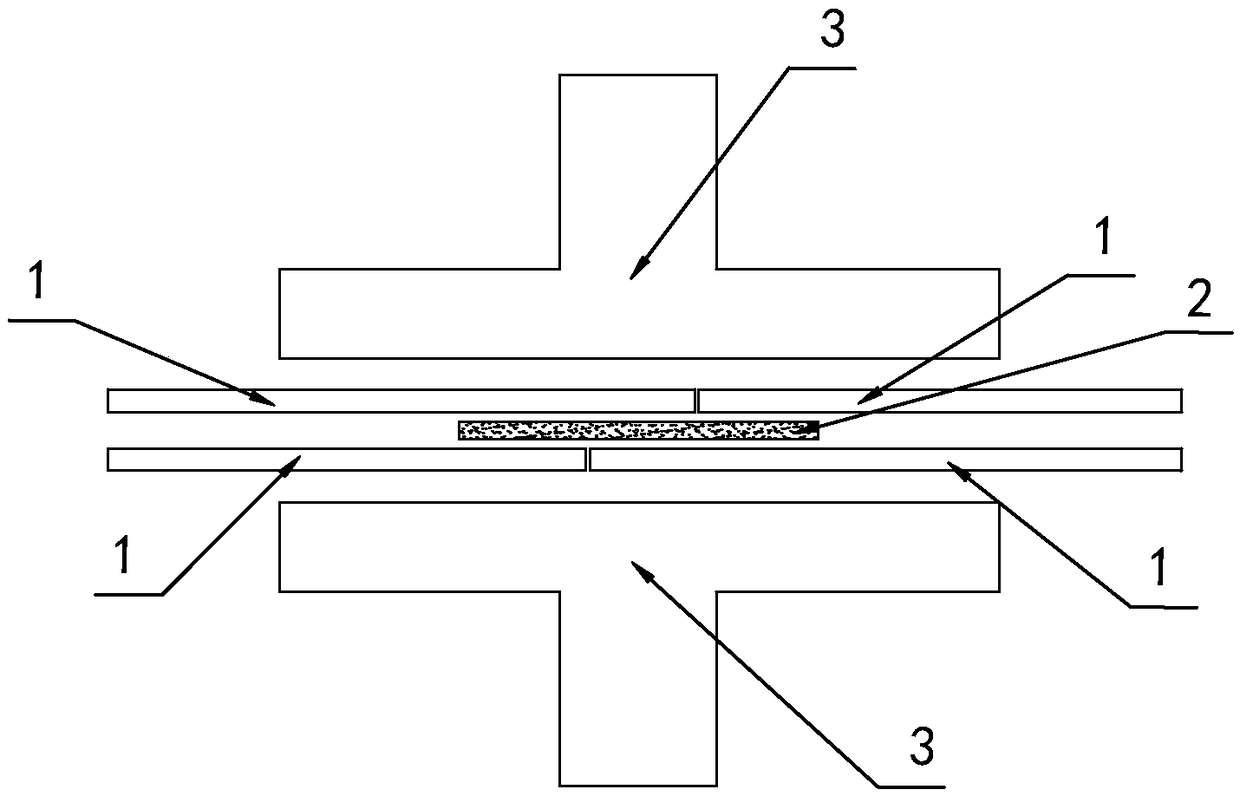

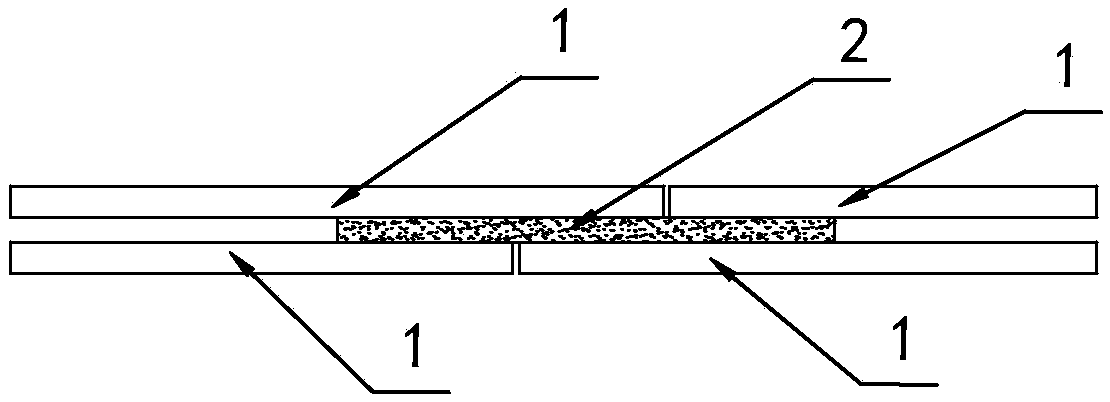

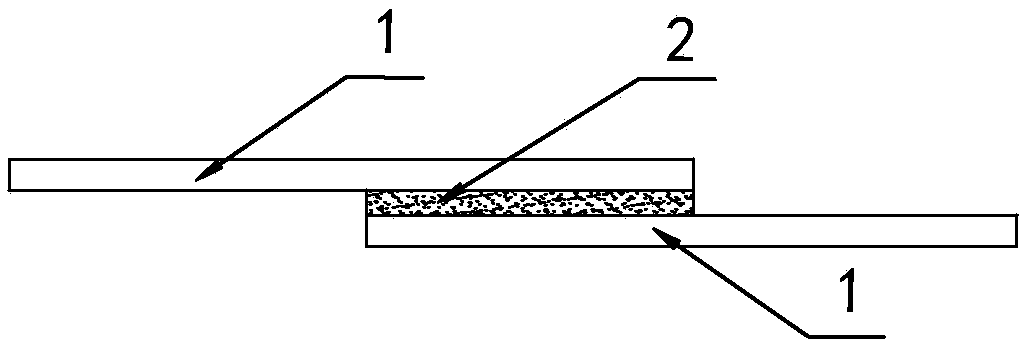

[0028] refer to Figure 2 to Figure 7 , the present invention is a fabric seam structure, including a plurality of fabric layers 1, at least two. Adjacent fabric layers 1 are all stacked at the joining position, and stacking can also be provided except at the joining position. For single-layer or multi-layer clothing, a certain width of lamination is required at the joint position, which can be staggered to avoid the joint end, and can further improve its firmness. For most multi-layer garments, in addition to the lamination of different layers, there are splicing between the same layers of fabric pieces. Generally, they are spliced on the same plane without forming protrusions or depressions, that is, forming a small seam. Adhesive layers 2 are arranged between the cloth layers 1 at the joint positions, and the thickness, width and length of the adhesive layers 2 are appropriately set according to the joint positions. The glued layer 2 is a hot-melt adhesive, generally p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com