Old roof waterproof refurbishment method and exposed weather-resistant color waterproof coating used

A waterproof coating and exposed technology, which is applied in asphalt coatings, roof insulation materials, coatings, etc., can solve the problems of partial maintenance, failure of waterproof and thermal insulation systems, and defects that are difficult to detect with the naked eye, so as to achieve no secondary pollution and excellent performance. Excellent anti-aging performance and film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

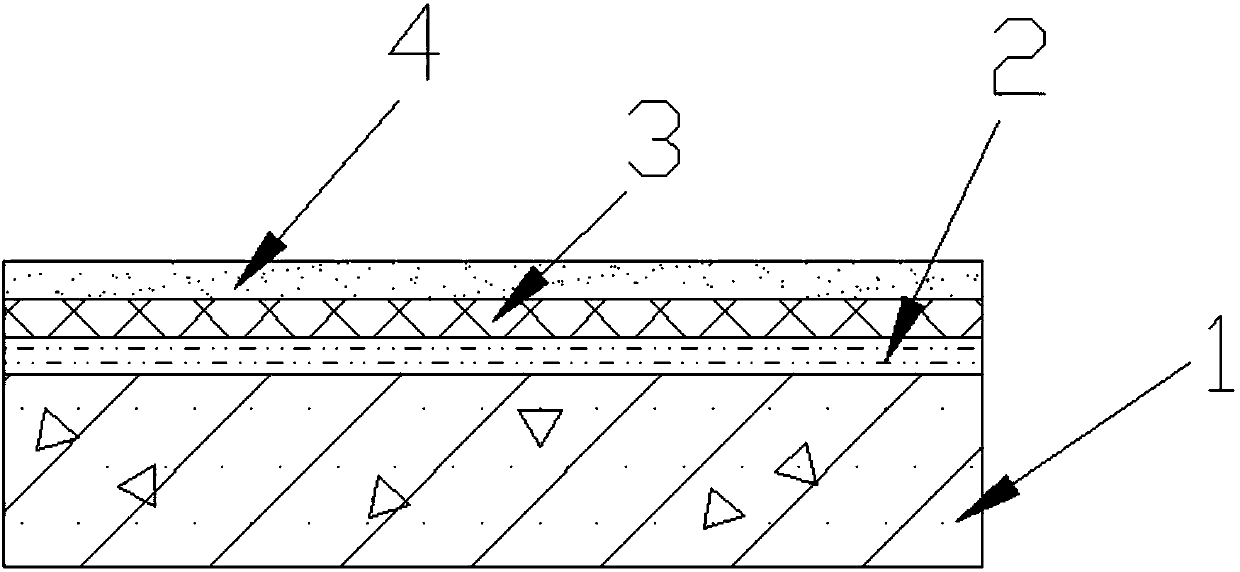

[0033] The old roof waterproof renovation construction method, first clean the base surface 1 of the old roof. Surface 1 is allowed to be wet but free of clear water, uneven, loose, bulging, peeling, cracked, pitted, etc., grease, dust, etc., and use a 2-meter ruler to check the flatness of base surface 1, and the deviation must not be allowed More than 5mm, no grease, dust, etc. Then strengthen the cracks on the roof. For wide cracks such as male and female corners, pipe root parts, expansion joints, deformation joints, and cracked base surfaces, use node sealing paste to carry out detail strengthening treatment; for narrow cracks (less than 1mm) spray water-based non-curing coating 2 (thickness 1.0mm, width about 200mm) and then lay non-woven fabric on it, the non-woven fabric is preferably needle-punched or spunlace non-woven fabric with a width of about 150mm, specification: 50 g / ㎡ , use a wide brush to lay the non-woven fabric flat and without wrinkles; the non-woven fab...

Embodiment 2

[0036] The difference from Example 1 is that the composition of the exposed anti-aging waterproof coating includes by weight: 50 parts of pure acrylic emulsion, 3 parts of propylene glycol, 55 parts of powder, 5 parts of filler and 4 parts of other auxiliary agents; The glass transition temperature of the pure acrylic emulsion is between -40°C; the powder is a mixture of quartz powder, titanium dioxide, ground calcium carbonate, kaolin, barium sulfate, wollastonite, mica powder, and talcum powder; the filler is A mixture of gaseous SiO2, ZnO, and quartz powder; the other additives include wetting agents, dispersants, defoamers, film-forming aids, cosolvents, preservatives, antifungal agents, thickeners, and pH regulators The mixture, the dosage of each component is dispersant 1.5, wetting agent 0.5, defoamer 0.8, preservative 0.3, antifungal agent 0.3, pH regulator 0.15, thickener 0.3, film-forming aid 1.5; The dispersant is a mixture of organic dispersant and inorganic disper...

Embodiment 3

[0038] The difference from Example 1 is that the composition of the exposed anti-aging waterproof coating includes by weight: 30 parts of pure acrylic emulsion, 2 parts of propylene glycol, 35 parts of powder, 3 parts of filler and 2 parts of other auxiliary agents; The glass transition temperature of pure acrylic emulsion is between -15°C and -40°C; the powder is talcum powder; the filler is quartz powder; the other additives include wetting agents, dispersants, and The dosage is 1 dispersant and 0.3 wetting agent; the dispersant is an inorganic dispersant; the thickener is cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com