Pluggable system and optical transceiver applicable to pluggable system

An optical transceiver and plug-in technology, which is applied in electromagnetic transceivers, instruments, optics, etc., can solve problems such as poor communication quality and insufficient connector coordination, and achieve the effect of reducing thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

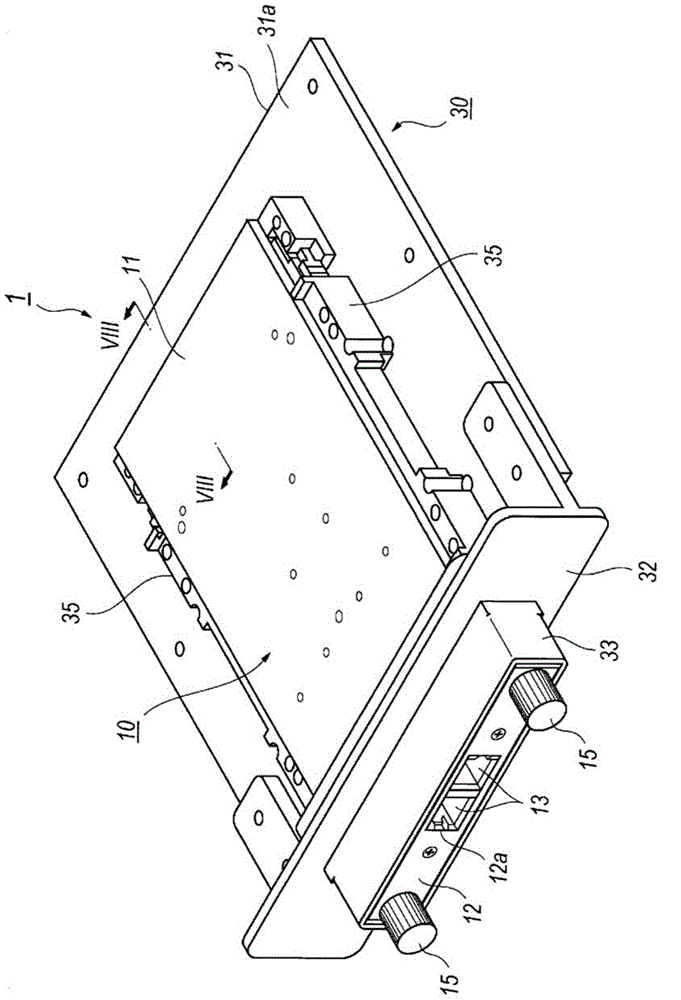

[0037] figure 1 is a perspective view of a plug-in system 1 comprising an optical transceiver 10 and a host system 30 according to a first embodiment of the present invention. The optical transceiver 10 belongs to a so-called plug-in optical transceiver conforming to the CFP standard.

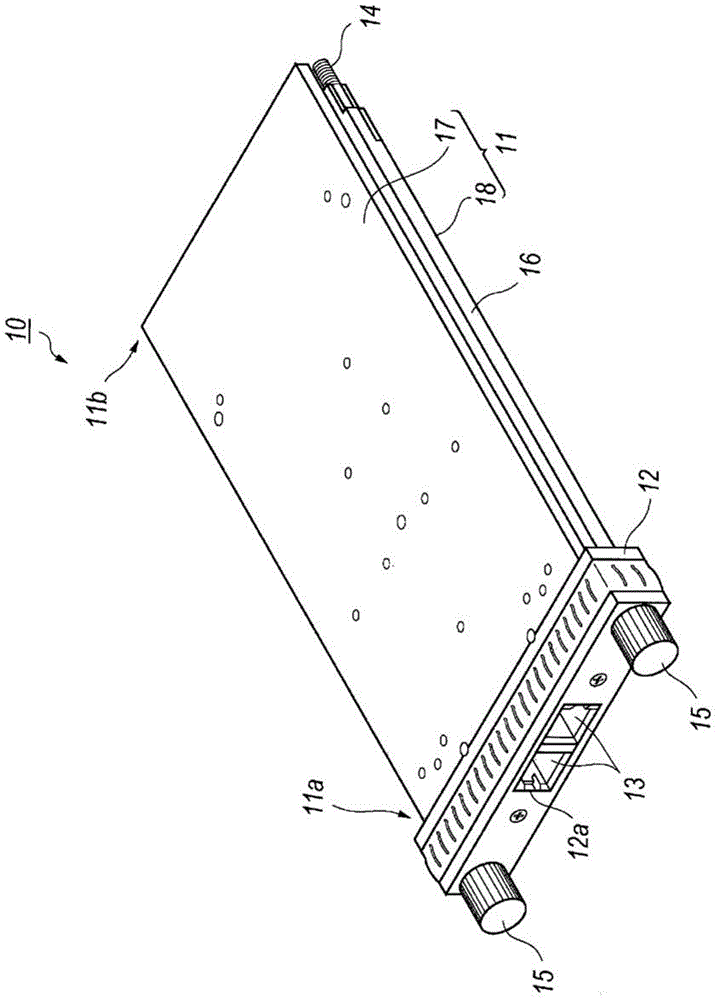

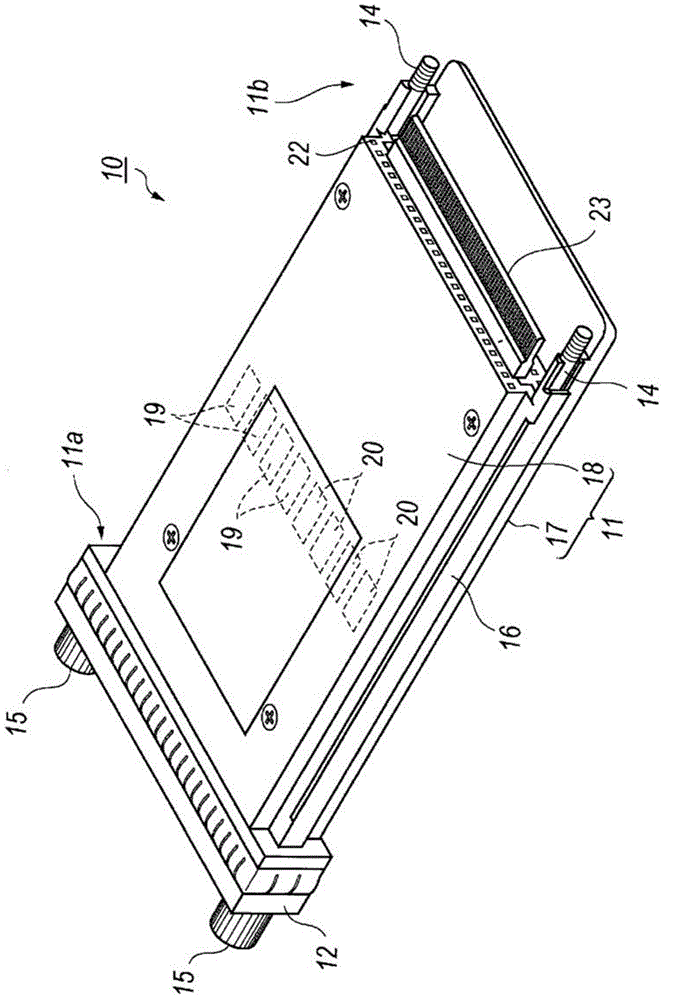

[0038] figure 2 It is a perspective view of the time transceiver 10 seen from the front top, image 3 The optical transceiver 10 is shown as viewed from the rear and below. Such as figure 2 and image 3 As shown, the optical transceiver 10 includes a housing 11 and a front cover 12 , and the front cover 12 is attached to the front end 11 a of the housing 10 . From the standpoint of heat dissipation and casting performance, the housing 11 may be made of, for example, aluminum or zinc.

[0039]In the following description, it is assumed that "front" refers to the side where the front cover 12 is fitted and "rear" refers to the other side where the electrical plug 23 is provided, for illus...

no. 2 example

[0054] A plug-in system including an optical transceiver and a host connector cover according to a second embodiment of the present invention will be described below. Figure 13 A plug-in system of a second embodiment is shown, wherein a plug-in system 1A includes an optical transceiver 10A and a host system 30A.

[0055] Figure 14 is a perspective view of the rear of the optical transceiver 10A; the optical transceiver 10A is provided with a rear 22A instead of the rear 22 of the previous embodiments. Other arrangements of the optical transceiver 10A are the same as those of the aforementioned optical transceiver 10 . The rear portion 22A is substantially flat, that is to say, the difference between the rear portion 22A of this embodiment and the previous embodiment may be that: the rear portion 22A is not provided with the concave portion 11A or the convex portion A21.

[0056] Figure 15 is showing Figure 13 A perspective view of host system 30A is shown. The differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com