Modularized lead protection system

A protection system and a modular technology, applied in the direction of construction and building construction, can solve the problems of easy gaps in bolt fixing, affecting the health of operators, and lack of proper protection measures, so as to reduce the labor intensity of material transportation and construction and labor costs, fast and convenient fixing, and the effect of ensuring radiation protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

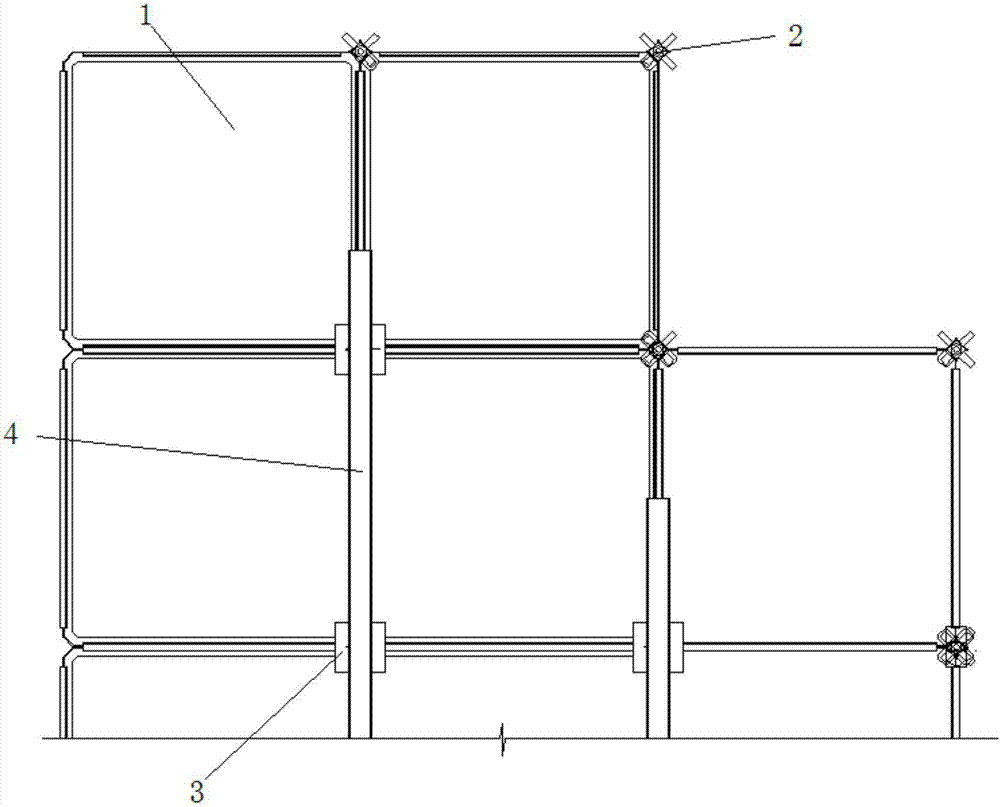

[0038] Such as figure 1 and figure 2 As shown, a modular lead protection system includes a mounting structure surface 100 and several rectangular lead protection modules 1;

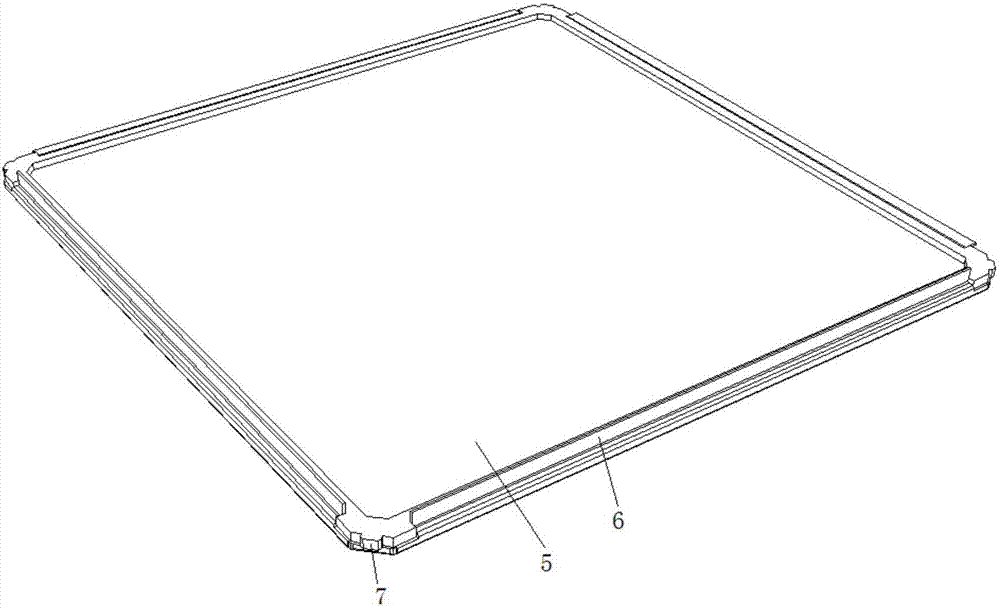

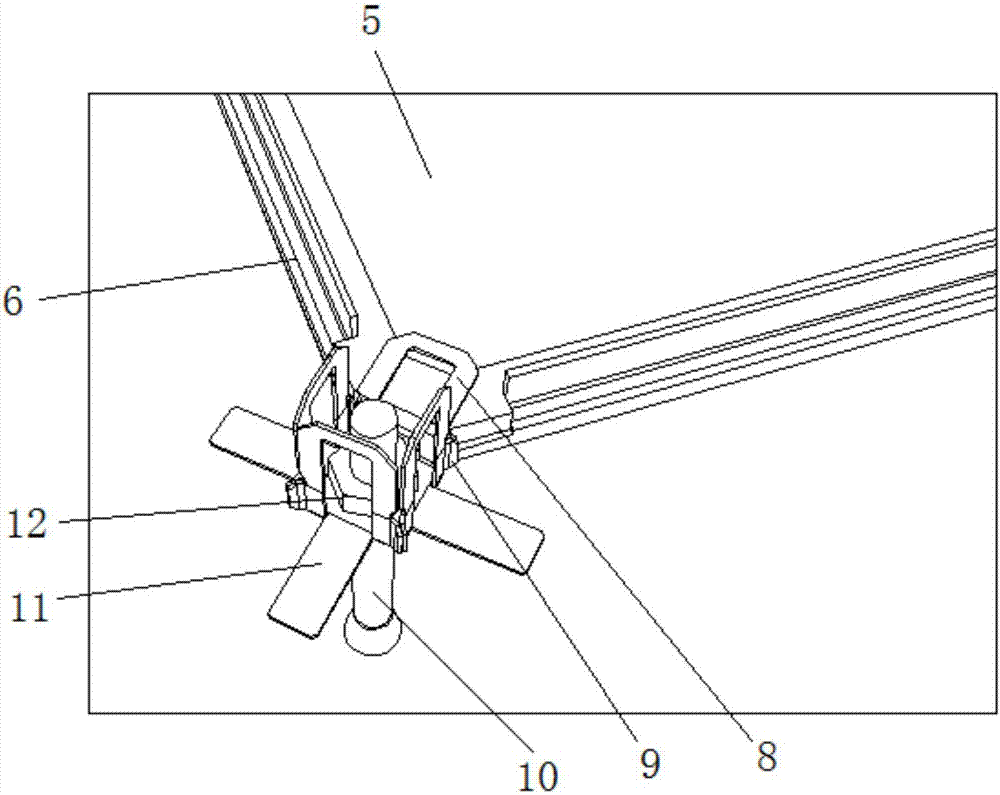

[0039] The rectangular lead protection module 1 includes a liner 5 and a main protective lead plate 6, and the main protective lead plate 6 covers the bottom surface of the liner 5 and is fixedly connected with the liner 5;

[0040] The edges of several rectangular lead protection modules 1 are offset against each other to form a modular lead protection board. The four corners of the rectangular lead protection modules 1 are respectively prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com