Fine carving device for industrial product machining and using method of fine carving device

An industrial product, Jingdiao technology, applied in the direction of metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as poor stability, endangering the health of workers, and inability to process industrial products, so as to achieve easy adjustment, improve use effect, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

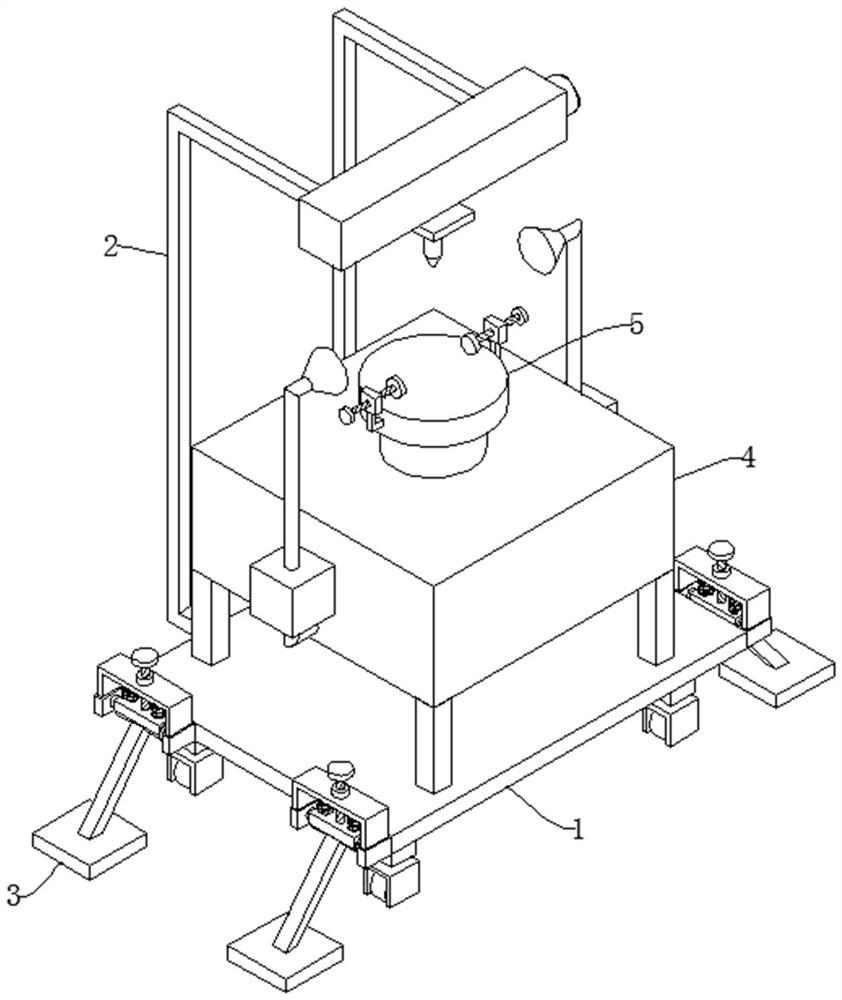

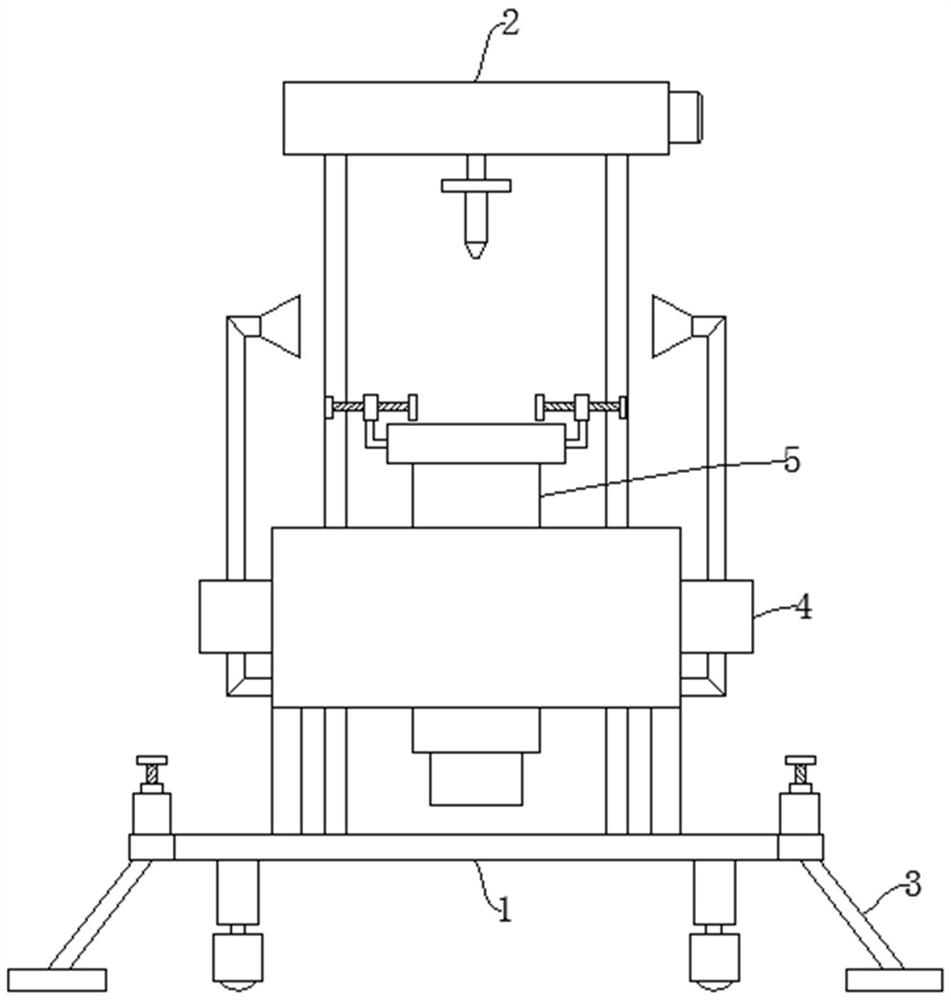

[0051] like figure 1 , figure 2 , Figure 4 , Image 6 , Figure 7 As shown, a fine carving device for industrial product processing includes a moving mechanism 1 for driving the device to move, a fine carving mechanism 2 for finely carving industrial products, and a fine carving mechanism 2 is fixed on the moving mechanism 1. It includes a fixing mechanism 3 for fixing the device, a purification mechanism 4 for purifying harmful gases generated during the fine carving process, and a rotating mechanism 5 for driving industrial products to rotate. The fixing mechanism 3 is installed on both sides of the moving mechanism 1 side, the purification mechanism 4 is fixed above the moving mechanism 1, and the rotating mechanism 5 is fixed above the purification mechanism 4;

[0052] The fixed mechanism 3 comprises a rotating shaft 301, a fixed sleeve 302, an oblique bar 303, a fixed plate 304, an end plate 305, a fixed frame 306, a threaded sleeve 307, a first threaded rod 308, a...

Embodiment 2

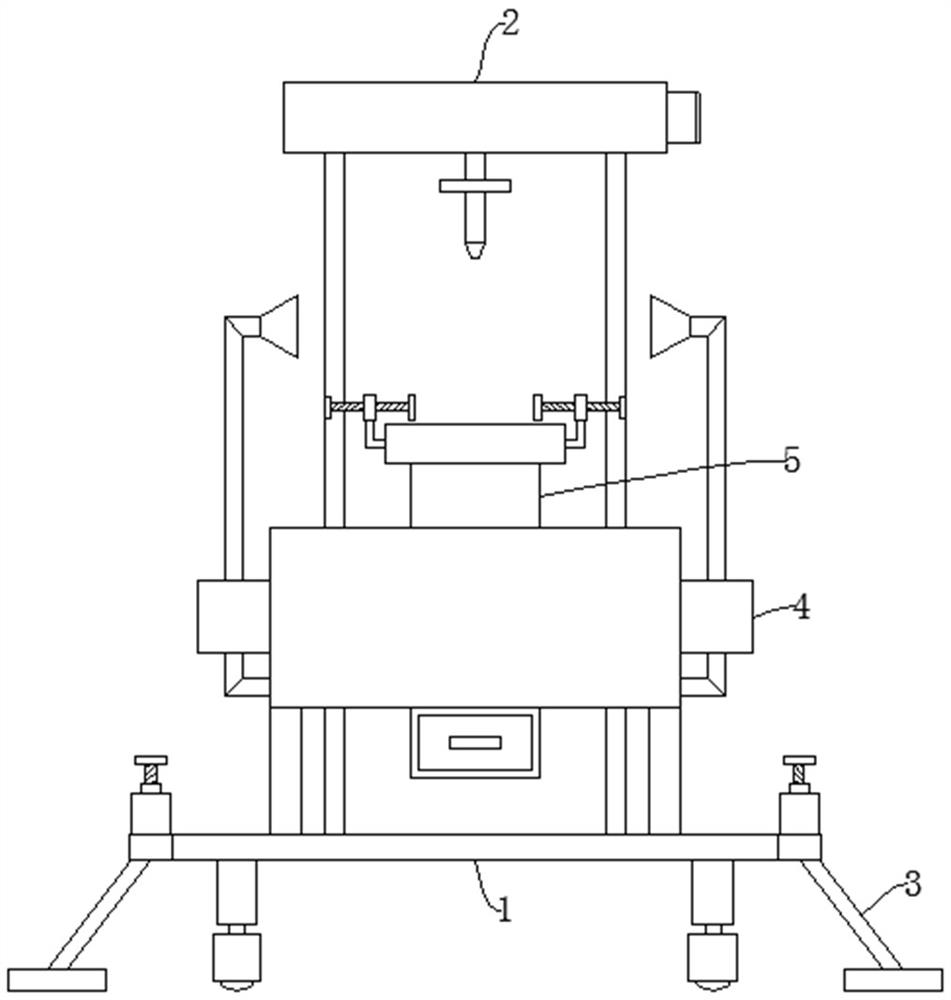

[0058] like figure 1 , image 3 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the threaded cover 4061, the fixed ring 4062, the movable ring 4063, the storage cylinder 4064, and the annular air mesh 4065 are replaced by the fixed shell 4066, the storage box 4067, the rectangular air mesh 4068, Handle 4069, the primary purified gas enters the storage box 4067 through the fixed cylinder 405, and the activated carbon in the storage box 4067 performs secondary purification on the gas, and the gas after the secondary purification is discharged through the rectangular ventilation net 4068, and the activated carbon in the storage box 4067 needs When replacing, pull the handle 4069, and the handle 4069 drives the storage box 4067 to move, and the activated carbon in the storage box 4067 can be replaced after the storage box 4067 is taken out from the fixed shell 4066.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com